We are thrilled to share some groundbreaking news that unfolded at the recently concluded India Warehousing & Logistics Show 2023 at Nesco, Goregaon. We proudly unveiled our latest innovation – Falcon, an AI drone that is set to redefine the landscape of logistics and warehousing in India.

The excitement in the air and the buzz of industry leaders converging, made apt setting for Assert AI to proudly launch Falcon, making history as the first company in India to introduce an AI Vision drone. The event served as a pivotal platform, and we emerged as true trailblazers, pushing the boundaries of innovation both within our country and beyond.

Massive Traction at Expo from Industry Giants

Assert AI made a groundbreaking mark by unveiling India’s first AI Vision drone. Falcon, showcased amidst the bustling atmosphere of the event, became an instant focal point, capturing the attention of industry leaders and professionals alike. Notable figures from esteemed companies such as Aditya Birla Group, Reliance Industries, Asian Paints, and other key players graced the occasion, underlining the collective acknowledgment within the industry of Falcon’s pivotal role in redefining the trajectory of inventory management in the warehousing sector. The event served as a platform for showcasing the transformative capabilities of Assert AI’s cutting-edge technology, highlighting its potential to revolutionize and streamline operations in the sector. The Falcon’s debut marked a significant milestone, sparking discussions and paving the way for a new era of efficiency and innovation in the logistics landscape of India.

Let’s dive into what makes Falcon the game-changer in the world of warehousing:

Falcon’s Features

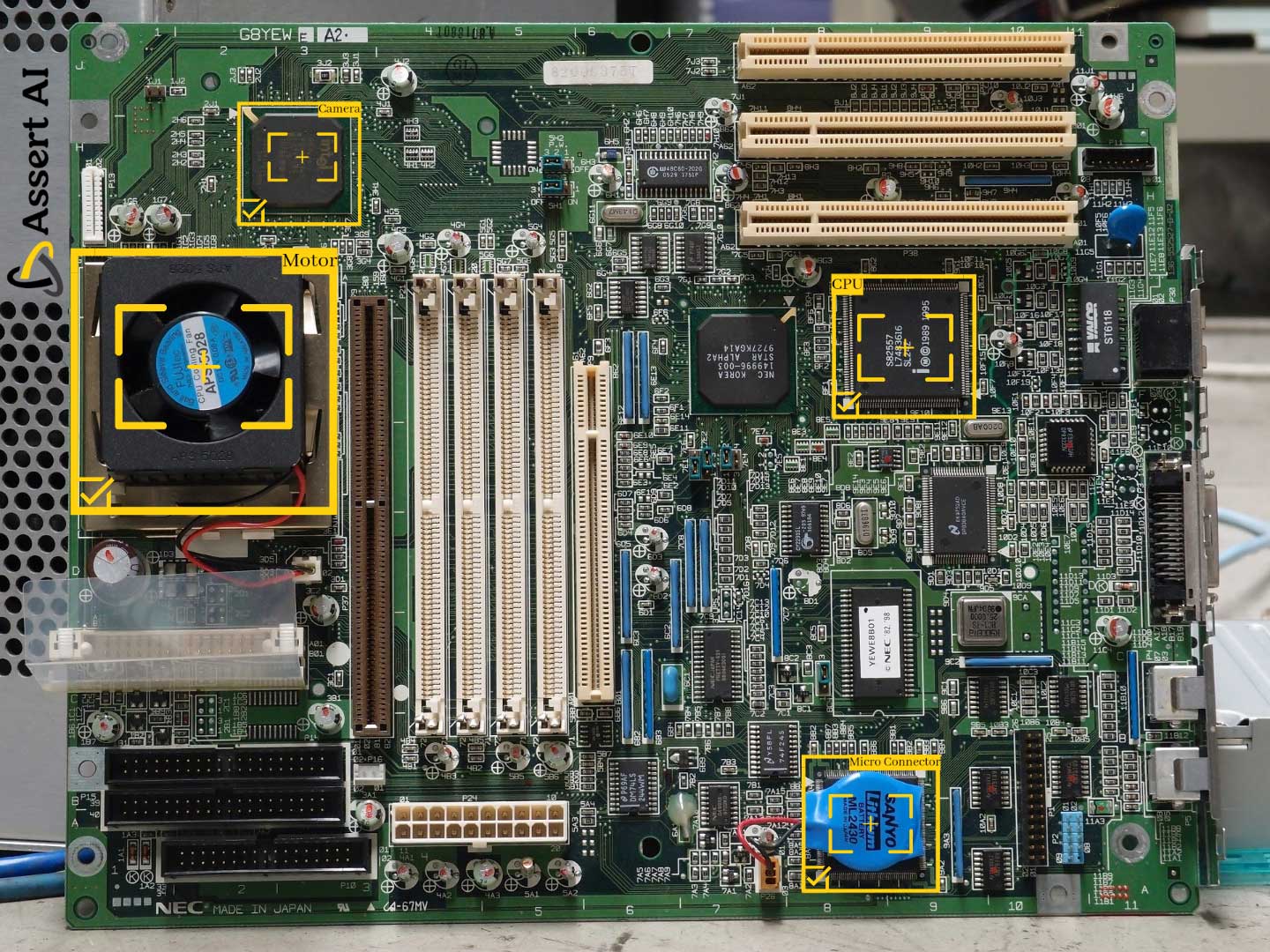

- Computer Vision Integration: Falcon is not your average drone. It incorporates cutting-edge computer vision technology, revolutionizing warehouse functioning by simulating human vision, mitigating human errors, and minimizing redundancy through its advanced automation capabilities.

- Semi-Autonomous Navigation: Falcon navigates through a combination of pre-programmed routes, real-time data analysis, and obstacle detection algorithms. Falcon can semi-autonomously navigate, optimizing routes, can be scheduled, deftly avoiding obstacles in real-time.

- Patented AI Technology: We take pride in our patented AI technology that powers Falcon, ensuring unmatched performance in inventory management.

- Data Analytics: Falcon doesn’t just fly; it analyzes. It provides data analytics, empowering businesses to make informed decisions promptly. Falcon seamlessly integrates with Warehouse Management Systems (WMS), ensuring efficient data transfer and enabling near real-time insights for streamlined decision-making in logistics and inventory management.

Applications that Soar

The applications of Falcon in warehousing are nothing short of awe-inspiring.

- Inventory Management: Falcon revolutionizes inventory management by seamlessly optimizing processes. It ensures precision and efficiency in tracking stock levels, employing advanced technology to streamline operations. This results in accurate data, empowering businesses to make informed decisions and maintain optimal inventory control.

- Product Mapping: Falcon generates precise product mapping in warehouse bins, enhancing inventory management by efficiently navigating, recognizing, and cataloging items. This optimizes data collection, ensuring real-time accuracy for inventory levels, item locations, and storage conditions, thereby streamlining decision-making processes and enhancing overall warehouse efficiency.

- Put-Away Audits: Falcon’s autonomous audits during the put-away process contribute to heightened inventory precision, enhancing overall warehouse organization and minimizing discrepancies.

- Empty Bin Detection: Leveraging advanced vision technology, Falcon not only identifies empty bins promptly but also efficiently locates missing packages, significantly reducing errors and optimizing retrieval processes.

- OCR: The inclusion of Optical Character Recognition (OCR) capabilities empowers Falcon to swiftly and accurately read labels and barcodes, streamlining the entire inventory tracking process for improved operational efficiency.

- Object Counting: Falcon’s prowess in precision counting extends to both individual objects and boxes, eliminating the need for manual counting. This ensures real-time, reliable inventory data, minimizing errors and facilitating more informed decision-making in managing stock levels.

We’re not just launching a drone; we’re launching a revolution. Falcon is more than a product; it’s a testament to Assert AI’s commitment to pushing the boundaries of innovation. We’re excited about the journey ahead as we continue to redefine what’s possible in the world of AI and logistics.

Stay tuned for more updates as we soar into the future with Falcon!