As supply chain managers, you understand the significance of inventory management in ensuring operational efficiency and customer satisfaction. With the help of AI-powered visual recognition technology, real-time stock management can be achieved, providing unparalleled accuracy and transparency in supply chain operations. In this post, we explore the benefits of real-time inventory visibility and how it can optimize supply chain management.

Benefits of Real-Time Inventory Visibility for Supply Chain Management

Inventory management automation is a critical challenge in supply chain management. Accurate and timely current stock status tracking and control are crucial for organizations to meet customer demand while minimizing excess inventory and associated costs. Inaccurate inventory records and inefficient inventory management can result in stockouts, delayed order fulfillment, reduced customer satisfaction, and decreased revenue. Additionally, inventory management becomes even more complex in global supply chains, where multiple locations, languages, and regulations must be considered. Therefore, efficient and effective inventory management is essential for successful supply chain operations and requires advanced technology and sophisticated processes.

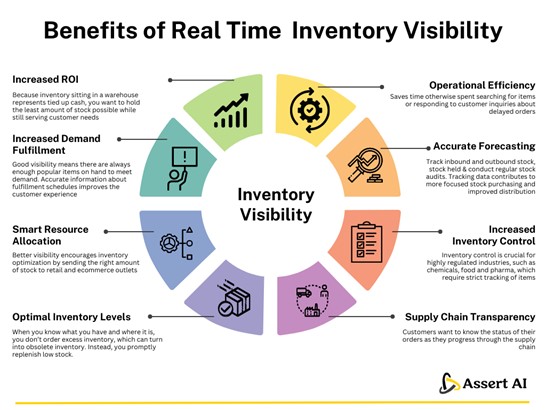

Here are the benefits of real-time inventory visibility:

Smart Resource Allocation

Stock management automation lets supply chain managers allocate resources effectively and automate the process. With accurate and timely insights, managers can prioritize high-demand items and ensure that resources are allocated to where they are needed the most.

Accurate Forecasting

Dynamic inventory monitoring enables accurate forecasting. By tracking inbound and outbound stock and conducting regular stock audits, managers can better predict demand and expand distribution. This leads to better decision-making and helps avoid excess inventory and stock shortages.

Optimal Inventory Levels

Stock optimization is critical for supply chain management. With real-time inventory visibility, managers can ensure optimal stock levels by avoiding overstocking and stock shortages. This improves efficiency and reduces the risk of inventory obsolescence.

Also Read: Common Warehousing Mistakes and How You Can Avoid Them

Real-time inventory visibility provides complete visibility of stock levels, location, and movement. This helps managers to track inventory in real-time and identify any issues before they become problems. This helps improve customer satisfaction by providing accurate information on order fulfillment status.

Increased ROI

With optimized inventory levels, supply chain managers can reduce inventory holding costs and increase cash flow. This allows companies to invest in other areas of the business.

Increased Demand Fulfillment

Efficient inventory management automation ensures that popular items are always in stock to meet customer demand. Accurate information about fulfillment schedules improves the customer experience and helps to build brand loyalty.

Supply Chain Transparency

Immediate stock availability tracking improves supply chain transparency by providing accurate information about stock levels and movement. This helps to identify bottlenecks and inefficiencies, leading to improvements in supply chain processes.

Continuous inventory status monitoring streamlines supply chain processes and improves operational efficiency. By reducing manual processes and providing real-time information, managers can optimize inventory management and focus on value-added activities.

Real-time inventory visibility is essential for supply chain management. By providing accurate and timely information, managers can optimize stock levels, improve customer satisfaction, and increase ROI. With the help of AI-powered visual recognition technology, real-time stock view can be achieved, providing unparalleled accuracy and transparency in supply chain operations.

Watch Video:

Top 10 Computer Vision Use Cases for Manufacturing Sector