Get ready for the future of manufacturing! The fourth industrial revolution (4IR) is taking the industry by storm, ushering in a new era of technological advancements. From computer vision to artificial intelligence, robotics, and the industrial internet of things (IIoT), 4IR technologies are revolutionizing the way factories operate. This transformation presents a multi-trillion dollar opportunity, paving the way for factories to achieve greater accuracy, efficiency, and safety. Thanks to the power of computer vision, machines can now automate strenuous tasks, detect product and machinery issues, and improve safety conditions for workers by leveraging visual data and converting it to actionable insights. With these cutting-edge technologies at our fingertips, the future of manufacturing is looking brighter than ever!

As competition in the industry heats up, companies are looking for innovative ways to stay ahead of the game. Manual quality inspection processes in manufacturing units are often time-consuming and prone to errors, leading to significant revenue leakage from faulty products and wasted resources. One technology that’s really stealing the show by offering automation? Computer Vision. This amazing AI technology allows computers to see and understand visual data, making it a game-changer for the manufacturing world. By using computer vision to optimize manufacturing processes, businesses can reduce revenue loss, boost productivity, and increase their bottom line.

Computer vision technology is a vital component of Industry 4.0, transforming the way manufacturing plants operate. AI algorithms can be applied to existing CCTV systems or additional drone cameras to reduce revenue loss in manufacturing units by automating quality control and inspection processes. This technology can help identify defects or anomalies in real-time, reducing the need for manual inspections and increasing efficiency and productivity.

Real-world examples and statistics demonstrate the potential value of this technology with estimated ROIs ranging from 10% to 60%. As the manufacturing industry becomes increasingly competitive, computer vision will become a secret weapon to dodge the revenue loss, gain a competitive advantage and take your manufacturing enterprise to the next level.

Assembly Line Optimization

Computer vision can optimize assembly lines by reducing the time and effort required to complete tasks. This technology can detect and track objects, recognize patterns, and analyze data in real-time. This allows manufacturers to identify bottlenecks, improve process flow, and reduce waste. One example of assembly line optimization using computer vision is Ford’s use of the technology to improve their paint job process. Tom Dougan, project manager, global paint applications at Ford said, “We are trying to find things that are almost beyond the threshold of human detection. The operators used to spend 70% of their time searching the vehicle over, maybe finding something, maybe not.”

He continued, “Now, (with computer vision technology), they are able to focus 90% of their time on polishing the vehicle and making sure that it meets our standards for quality.” By using cameras and sensors, they are able to identify and eliminate defects in real-time, reducing their paint rejection rate by 80%.

Defect Detection

Another application of computer vision that can identify defects in products, such as scratches, cracks, or missing components. By detecting defects early in the manufacturing process, companies can reduce waste, improve product quality, and avoid costly recalls. By using AI-powered visual inspection, Nestle is able to identify and remove defective and broken products, detect even transparent objects in any position and detect laws, missing spoons etc before they reach the market, reducing their waste by 30%.

Nestle also is using computer vision to boost manufacturing efficiency in some of their KitKat manufacturing lines that are self-regulating. “We have loops in those lines, so they detect the product quality, they measure the attributes of the wafer, for instance, and then they regulate the process back,” said Stefan Palzer, Chief Technology Officer. “So, it’s a self-controlling mechanism. But we are also employing machine learning approach for preventive maintenance. So, that allows us to reduce downtime of our lines”, he added.

Predictive Maintenance

Computer vision can also be used for predictive maintenance, which allows manufacturers to identify and fix potential problems before they cause downtime or breakdowns. This technology can monitor machines and equipment, analyze data, and predict when maintenance will be required. This can save companies time and money by reducing unplanned downtime and avoiding costly repairs. One example of predictive maintenance using computer vision is Siemens’ use of the technology to monitor their gas turbines. By using AI-powered visual inspections, they were able to detect and repair potential issues before they caused downtime, correcting costly mistakes before they occurred, resulting in a 10% increase in turbine availability.

Volkmar Sterzing, Head of RG Learning Systems, Seimens AG states, “We were surprised at how much better the gas turbines could be run this way. To ensure that a gas turbine runs optimally, you always have to search for a balance in which several undesired effects such as combustion dynamics, loss of efficiency and emissions are kept as low as possible. If you improve one variable, you will worsen a different one. Artificial intelligence knows how to find the sweet spot.”

Quality Control

Finally, computer vision can be used for quality control, which allows manufacturers to ensure that their products meet the highest standards. This technology can analyze visual data, identify defects, and sort products based on their quality. This can help companies reduce waste, improve product quality, and increase customer satisfaction. Coca-Cola’s use of computer vision to ensure quality control using an automated visual AI based system is a real-world example of Computer vision visual inspection that detects liquid level, bottle cap missing, deformed bottles, missing label, and more, reducing their defect rate by 30%.

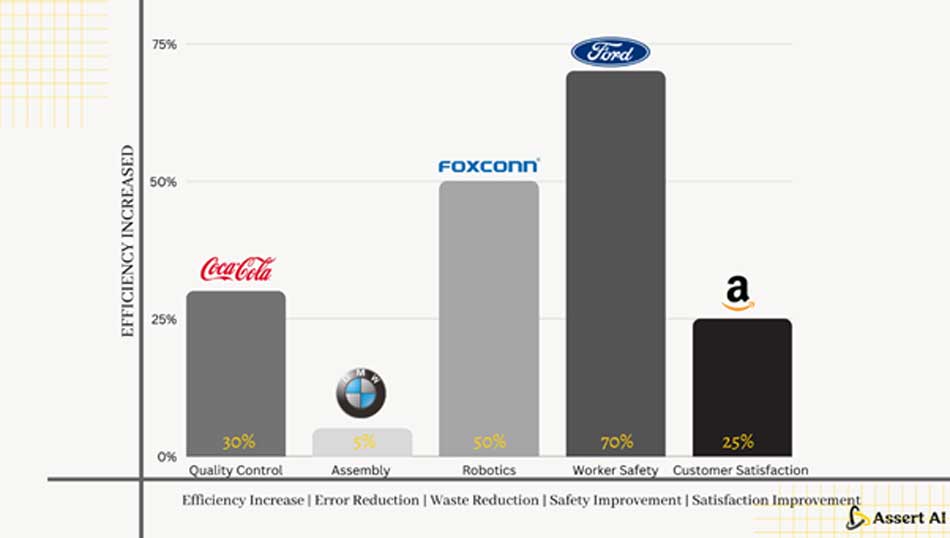

Estimated ROI of Computer Vision Technology in Manufacturing Sector

The potential return on investment (ROI) of computer vision in manufacturing is a captivating realm with varying outcomes. Delving into the depths of assembly line optimization, we witness ROI spanning from 10% to an astounding 30%. In the realm of defect detection, the ROI ascends to remarkable heights, reaching from 20% to an impressive 50%. As we unravel the prospects of predictive maintenance, ROI manifests within the captivating range of 15% to a staggering 40%. Finally, venturing into the realm of quality control, ROI soars to remarkable levels, encompassing an extraordinary spectrum of 25% to a mind-boggling 60%. These estimations, grounded in real-world examples and compelling statistics, underscore the immense value that computer vision can bring to the manufacturing industry.

Wrapping up

Computer vision is a powerful technology that can help dodge revenue loss for manufacturing plants. By optimizing assembly lines, detecting defects, predicting maintenance, and ensuring quality control, companies can reduce waste, improve efficiency, and increase profitability. Real-world examples and statistics demonstrate the potential value of this technology, with high ROI. As the manufacturing industry becomes increasingly competitive, computer vision will become an essential tool for companies seeking to gain a competitive advantage.