AI in Manufacturing presents a transformative opportunity to revolutionize the industry entirely. Be it increased productivity, reduced expenses, enhanced quality, or minimized downtime, while large factories stand to gain significantly, it’s imperative for smaller manufacturing units to grasp the accessibility of high-value, low-cost AI solutions.

At Assert AI, we pride ourselves on offering cutting-edge computer vision solutions that redefine the standards of inspection efficiency and accuracy. Our innovative approach leverages existing CCTV infrastructure or seamlessly integrates additional cameras to meet specific inspection requirements. With our AI vision algorithm, we optimize inspections using our patented AI models for superior defect detection, item classification, optical character recognition, and presence/absence checks.

Applications in Manufacturing

Let’s delve into potential applications of computer vision technology, drawing insights from real-world scenarios to showcase how it addresses various industrial challenges.

1. Injection Molding Machine Monitoring

By integrating AI image recognition with IP cameras, we enable real-time detection of mold closure, preventing machine malfunctions and minimizing downtime.

2. Inspection of Stamped Metal Parts

(create ok tested, match 99.2%)

Utilizing AI models trained on various defect videos and images, our solution ensures accurate detection of imperfections on stamped metal parts such as Body panels, Seat rails, ECU housings, Brake backing plates, Radiators, Engine oil pans, Bumper reinforcement bars and other parts in the automotive industry.

3. Visual Inspection of Automotive Weld Beads

With AI-powered simulations, our system can identify weld bead defects under varying brightness, ensuring reliable inspection regardless of lighting conditions. It involves visually examining welds to identify surface discontinuities. Visual Inspection also ensures that a weld meets a standard or engineering specification.

4. Rubber Tire Inspection

Through Optical Character Recognition (OCR) powered by AI, our system ensures precise identification of serial numbers on rubber tires, facilitating correct matching with outer tires during production.

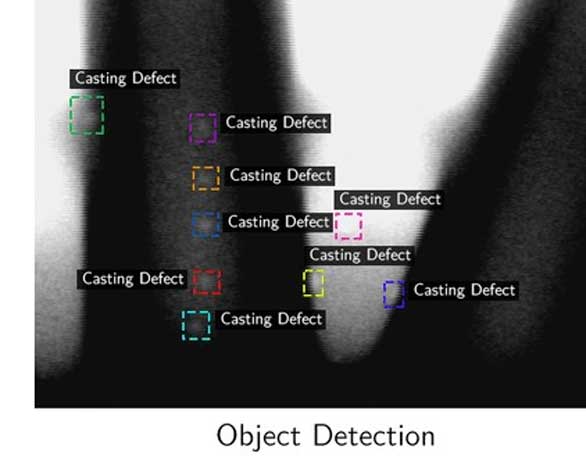

5. AI Defect Detection for Spiral-Surfaced Metals

Using AI segmentation tools, our system learns to recognize subtle defects on spiral-surfaced metal parts, refining production quality.

6. AI Detection of Welding Defects

Leveraging AI, our system quickly identifies irregular-shaped welding defects, ensuring consistent welding quality in hazardous environments.

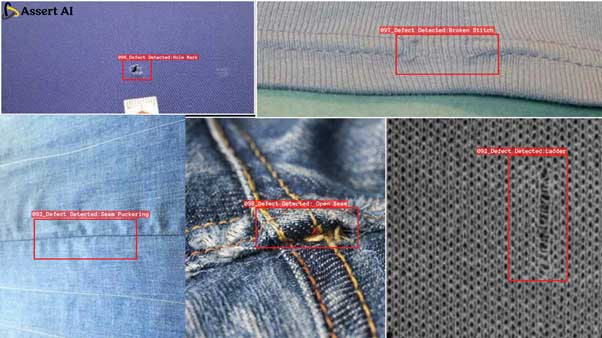

7. Defect Detection and Classification for Textiles

With AI-based defect detection, our system enhances textile quality control, swiftly identifying and classifying defects for improved production efficiency.

8. AI Quality Control for Medical Consumables

Our AI inspection system accurately detects assembly errors in safety syringes, optimizing production processes and enhancing product reliability.

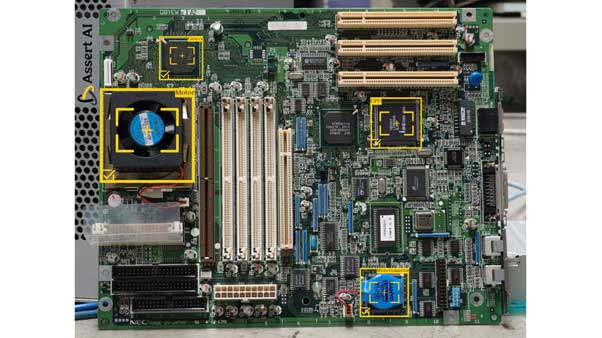

9. Detecting Faulty and Missing Laptop Components

Through AI-powered visual inspection, our system identifies missing parts or assembly errors in laptops, improving yield and efficiency.

10. Blister Pack Inspection Using AI

With AI-driven inspection, our system ensures accurate detection of packaging defects in pharmaceutical blister packs, enhancing product reliability.

11. Visual Inspection of Glass Bottles

Utilizing advanced image processing, our AI system automates defect detection on glass bottles, ensuring consistent product quality.

12. Quality Inspection of Golf Clubs

Through AI-based defect recognition, our system enhances the finishing quality of golf club heads, meeting consumer expectations.

13. AI Inspection of Plastic Buckles

With multi-tool AI defect detection, our system accurately identifies defects on plastic buckles, enhancing production efficiency.

14. Inspecting Safety Certification Marks

Leveraging AI anomaly detection, our system ensures the accuracy of safety certification marks, enhancing product reliability.

15. Inspecting Aluminum Product Packaging

Through AI-powered anomaly detection, our system identifies printing defects on aluminum packaging, maintaining brand reputation and consumer trust.

Key Features

- AI Training: Our defect detection system can learn new items from as few as a few video samples. Our AI experts annotate this data to reach high accuracy levels and reduce false alerts.

- On-prem deployment: Our on-prem deployment feature ensures data security and compliance by hosting our AI solutions directly within your facility, providing peace of mind and control over sensitive information.

- Intuitive Interface: Assert AI’s user-friendly Dashboard lets users receive real-time alerts, view insights around efficiency, productivity, and asset monitoring on multiple devices in real-time. The dashboard control hierarchy is based on user roles, offering easy-to-understand charts and graphs with customizable filters. On-prem deployment ensures data security and compliance.

- Diverse AI Vision Applications: Assert AI offers outstanding performance and versatility for a range of AI inspection applications, providing tailored automation solutions for specific industry needs. Real-time actionable insights within 2-3 seconds maximize client ROI.

- AI Drone-based Solutions: Our AI drone Falcon is ideal for monitoring hard-to-reach areas, blind spots, and makeshift infrastructure.

Computer vision technology empowered by AI offers unparalleled capabilities in revolutionizing quality and safety inspection across various manufacturing sectors. By harnessing these cutting-edge solutions, companies can unlock new levels of efficiency, reliability, and competitiveness in today’s dynamic marketplace. At Assert AI, we’re committed to driving innovation and empowering manufacturers to thrive in the digital age. Join us in embracing the future of manufacturing with AI-driven quality and safety inspection solutions.