In today’s fast-paced business landscape, quality control plays a critical role in ensuring customer satisfaction and brand reputation. However, traditional quality control processes often come with hidden costs that can significantly impact operational expenses. In this blog post, we’ll explore the various ways your current quality control process may be impacting your bottom line and how implementing computer vision solutions can save you money while enhancing efficiency and accuracy.

The Cost of Human Error: More Expensive Than You Think

Industry statistics reveal that human error accounts for a significant portion of quality control issues, leading to costly rework, product recalls, and dissatisfied customers. According to a study by the American Society for Quality (ASQ), the cost of poor quality can reach up to 15-20% of a company’s total revenue. This means that every mistake made during quality control activities can directly impact your profitability.

The Needle in the Haystack: Inefficient Inspection Processes

Traditional quality control often relies on manual inspection processes that involve visually scanning products for defects. This approach is not only time-consuming but also prone to oversight. It’s like searching for a needle in a haystack without a magnet! When a single defective product slips through the cracks, it can lead to customer complaints, returns, and even damage your brand’s reputation.

The Butterfly Effect: How One Defect Can Cause Havoc

Just like the delicate balance in nature, one defective product can cause a ripple effect throughout your supply chain. Imagine a single faulty component used in the manufacturing process of a larger product. If not detected early, it could result in a cascade of defects, expensive product recalls, wasted materials, and a considerable drain on operational costs. The impact is similar to a small butterfly flapping its wings and causing a hurricane on the other side of the world!

Human Limitations vs. Machine Precision: The Battle of Accuracy

When it comes to accuracy, humans have their limitations. Fatigue, distractions, and inherent subjectivity can all affect the consistency and reliability of manual inspections. On the other hand, computer vision solutions powered by AI can analyze vast amounts of visual data in real-time, ensuring precision and accuracy at a level unattainable by human inspectors alone. It’s like comparing a fleet of tireless robots to human inspectors with limited attention spans.

Cost-Efficiency Revolution: Embracing Computer Vision Solutions

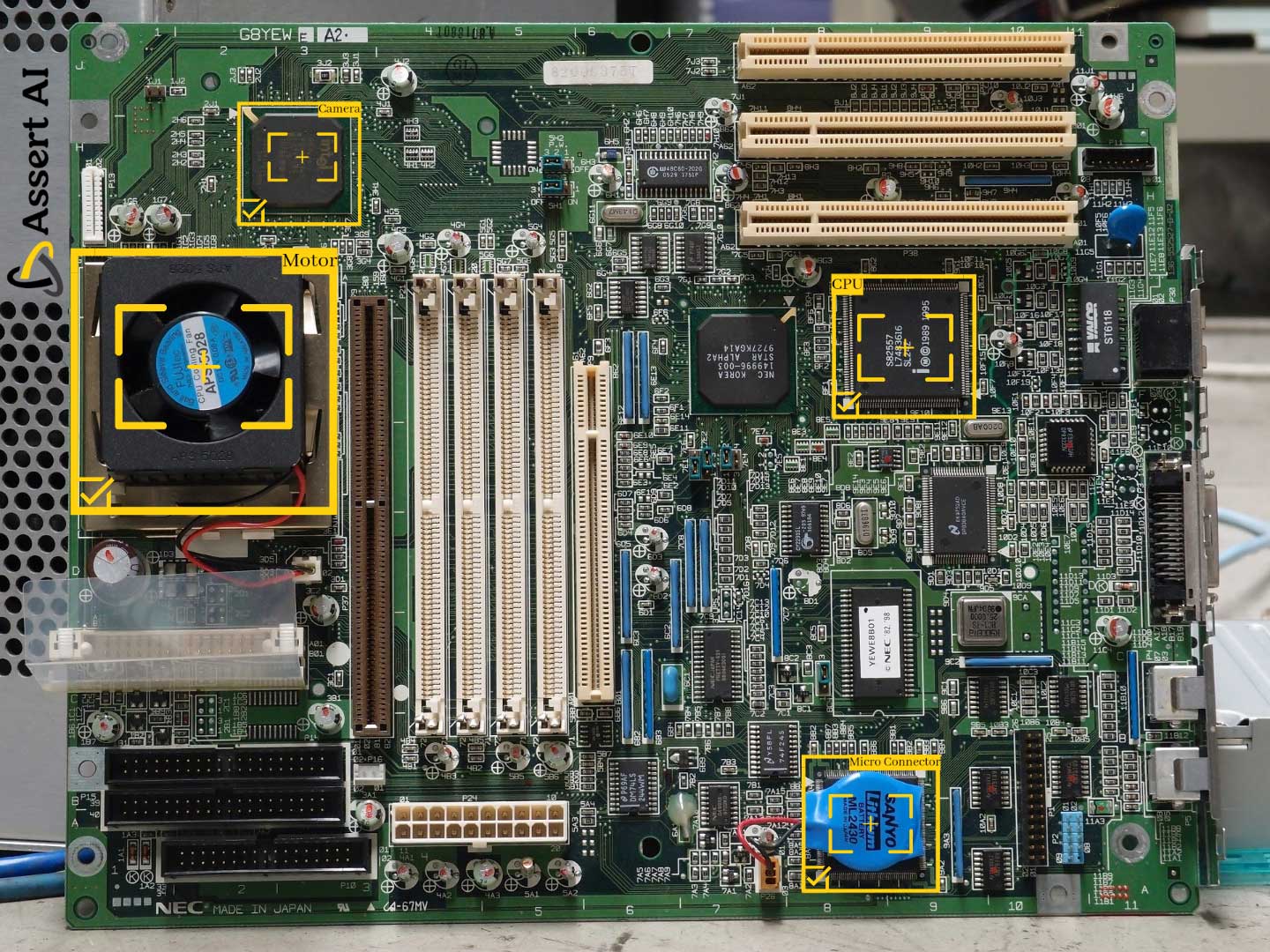

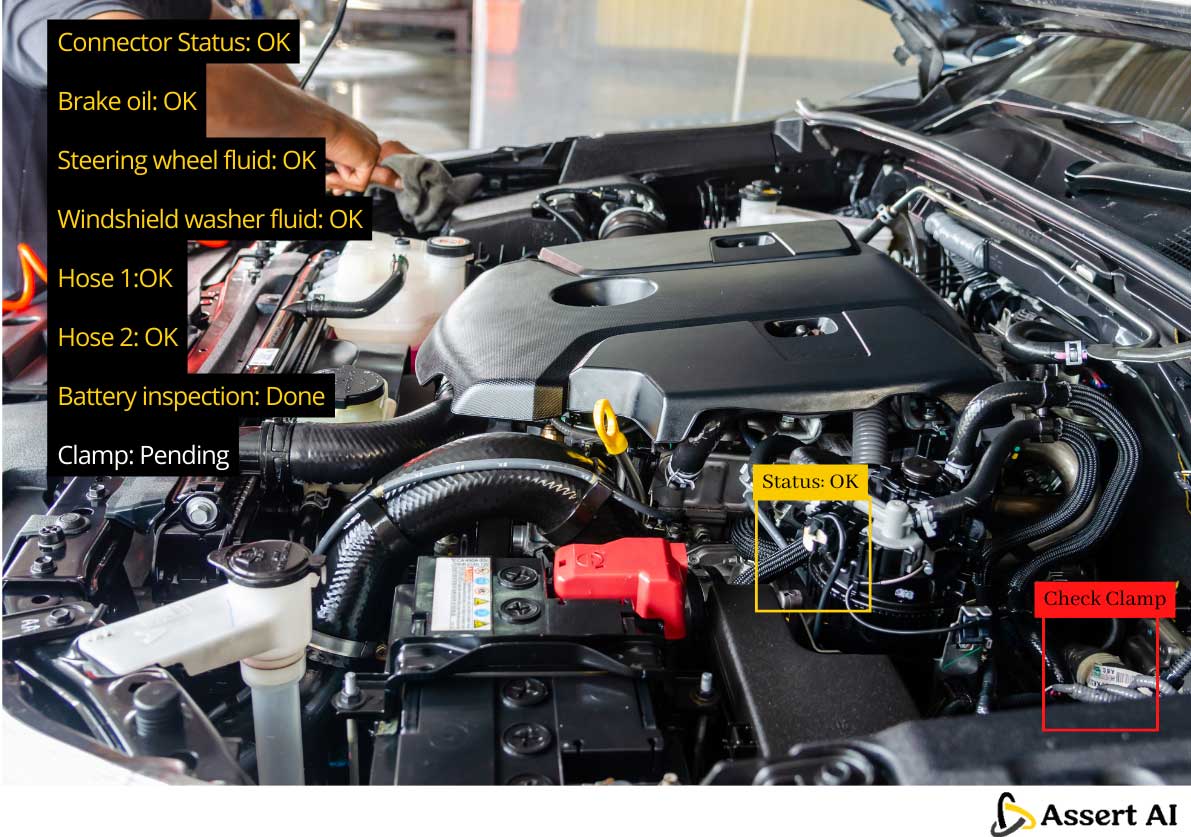

The good news is that advancements in computer vision technology offer a cost-efficient solution to transform your quality control process. Computer vision systems can autonomously scan and analyze products, detecting even the tiniest defects with unmatched precision. By reducing human error, minimizing inspection time, and optimizing resource allocation, computer vision solutions help businesses cut operational costs while maintaining quality standards.

From Reactive to Proactive: Predictive Maintenance

Computer vision systems not only identify defects but also provide valuable insights for predictive maintenance. By continuously monitoring equipment and machinery, these systems can detect signs of wear and tear, enabling businesses to schedule maintenance activities proactively. This shift from reactive to proactive maintenance helps prevent costly breakdowns, extends the lifespan of assets, and optimizes production efficiency.

Building Trust with Customers: Enhanced Brand Reputation

Implementing computer vision solutions not only saves operational costs but also boosts customer satisfaction and brand reputation. By ensuring consistent quality and minimizing defects, you can gain your customers’ trust, leading to higher customer loyalty and positive word-of-mouth. After all, customers value reliable products, and an investment in quality control technology demonstrates your commitment to delivering exceptional value.

Wrap up

Your current quality control process might be silently siphoning away your profits through human error, inefficient inspection methods, and costly defects. Embracing computer vision solutions can help you save operational costs, enhance accuracy, and elevate your brand’s reputation. By leveraging AI-powered technology, you can transform your quality control process into a more efficient, accurate, and cost-effective operation. Remember, investing in the right tools today will ensure a brighter and more profitable tomorrow. So, why wait? It’s time to harness the power of computer vision and revolutionize your quality control process.