The landscape of supply chain management is ever-shifting, and the year 2024 promises to be a pivotal moment in this journey. As we gear up for the challenges and opportunities ahead, let’s explore the trends that will reshape the industry’s priorities and strategies.

The Unravelling of Supply Chain Priorities

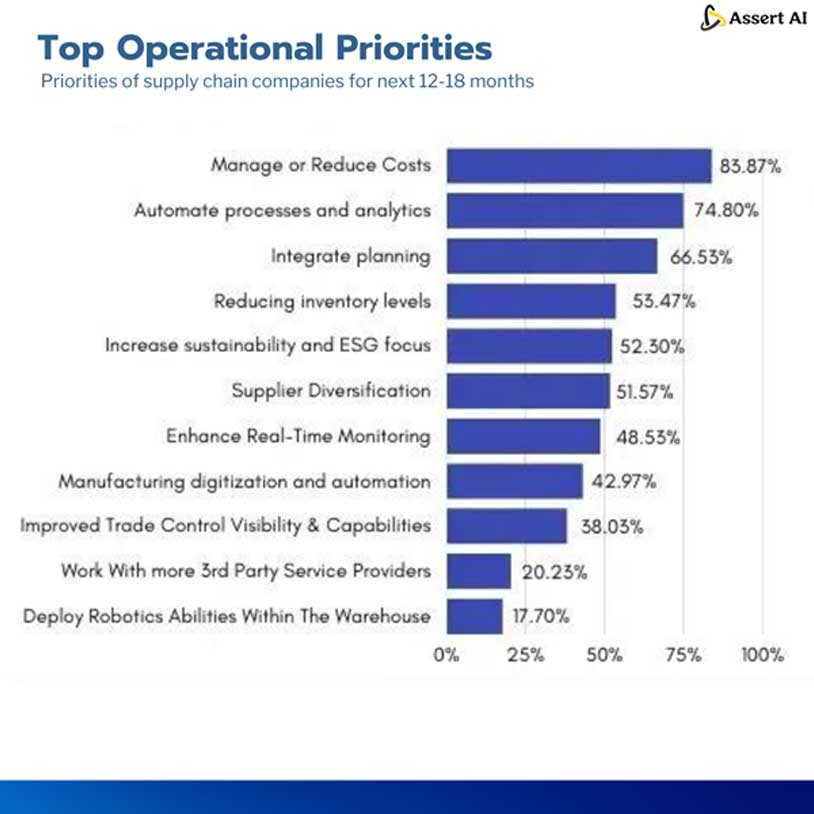

1. The Cost Conundrum

In today’s economy, cost management is a battle many companies face head-on. The supply chain stands as a formidable ally in the quest to manage or reduce costs. Optimizing transportation, warehousing, and inventory management is the key. Leveraging strategies like optimized routing, shipment consolidation, and the adoption of cutting-edge automation technology can significantly reduce costs. Streamlining warehouse operations, reducing operational costs, improving efficiencies and enhancing throughput add to the arsenal. The formulaic science behind cost reduction is also based on optimizing inventory levels for improved cash flow and profitability.

2. Automation, Analytics, and the Supply Chain

Automation is the force reshaping the supply chain landscape. Companies are rapidly adopting technologies like artificial intelligence, computer vision, drones, and robotics to automate processes, enhance efficiency, and trim costs. Automation, in all its forms, empowers companies to streamline operations, minimize errors, and boost overall productivity. The analytical prowess of machine learning and data-driven insights is the compass guiding companies to identify inefficiencies and steer toward improved decision-making.

3. The Unison of Planning

In an interconnected world, supply chain planning needs to be a harmonious symphony. Companies must bridge the planning gap across departments, partners, and suppliers. Collaborative integration ensures a seamless flow of goods and services. Sharing insights and coordinating activities are the bedrock for optimizing supply chain operations, reducing lead times, and elevating customer service.

4. The Quest to Trim Inventory

Effective inventory management is the cornerstone of a well-oiled supply chain. Excess inventory can hold up capital, inflate costs, and undermine profitability. Balancing the scales through optimized inventory levels, aligning supply with demand, and taming the specter of stockouts is the name of the game. With the aid of demand forecasting and inventory management tools, companies can strengthen inventory planning, slash excess stock, and accelerate their cash flow.

5. Embracing Sustainability and ESG

Sustainability is the new cornerstone, impacting customers, investors, and regulators. Adhering to sustainable practices and the adoption of Environmental, Social, and Governance (ESG) criteria can polish a company’s brand reputation, court customers, and secure long-term success.

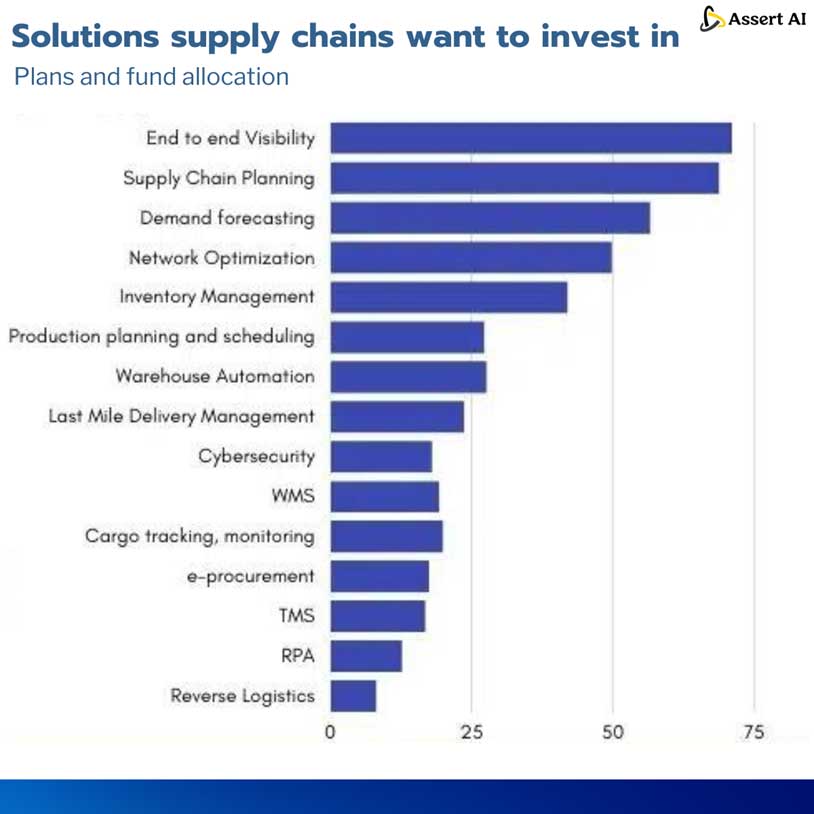

The Pioneering Solutions

With these priorities in mind, let’s unveil the top solutions companies are ardently embracing to turbocharge their supply chain performance.

2. Supply Chain Planning: Demand forecasting, capacity planning, and production scheduling algorithms are the wizards in optimizing supply chain operations. Offering precise forecasting, predictive maintenance, diminished lead times, and a tighter rein on stockouts.

3. The Power of Demand Forecasting: An elemental component of inventory management, demand forecasting stands as a lighthouse. It uses historical data, market trends, customer behaviour and even insights generated through visual inputs that never existed before, to illuminate the path of accurate demand prediction, optimizing inventory levels, nurturing cash flow, and bolstering profitability.

4. Network Optimization: Crucial for a cost-efficient voyage and improved customer service, network optimization tools are the compass. They help streamline routing, optimize vehicle lifecycle, shrink transit times, and elevate delivery performance. All of which translates to cost reduction, customer satisfaction, and a competitive edge.

5. Inventory Management Solutions: Inventory management is the heart of supply chain management. Companies wielding these tools can fine-tune inventory levels, unmask slow-moving items, and harmonize reorder points. Investing in these solutions means curbing excess inventory, minimizing stockouts, and improving overall supply chain efficiency.

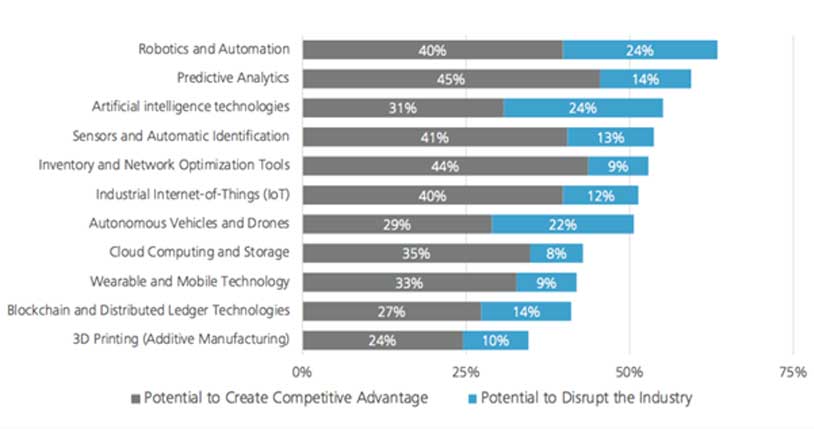

AI Pioneers in Supply Chain Management: Unveiling the Numbers

In the realm of supply chain management, the adoption of artificial intelligence (AI) is a tale that’s still unfolding. According to a recent report from MHI and Deloitte, a mere 12% of businesses have taken the plunge into AI integration in their supply chain operations. To add to the intrigue, AI has witnessed a rather unexpected shift in its disruptive potential. It’s no longer reigning as the undisputed champion; it now sits in fourth place, bowing to sensors and automatic identification, as per the same study’s latest edition.

But what lies beneath these numbers? A McKinsey global survey endeavours to unravel this enigma. The survey delves into the cost and revenue impact of AI adoption across 33 use cases and eight business functions, including the realm of supply chain management. The findings are nothing short of intriguing. A majority of early AI adopters (63%) have witnessed revenue increases, and nearly 44% have reported significant cost savings.

The spotlight falls on the high performers, where the impact is truly profound. They are three to four times more likely to report seismic shifts exceeding ten percent in terms of both revenue and cost metrics. The numbers tell a compelling story: 63% of these high performers experience notable revenue bumps, and a closely following 61% achieve commendable cost reductions. The AI trailblazers are silently but decisively reshaping the supply chain landscape. It’s not just about the numbers; it’s about a new era dawning in supply chain management.

The Enigmatic Rise of Elastic Logistics

Lean processes have paved the way, but in this new era, supply chains demand an elastic touch. Elastic logistics ushers in the ability to adapt to market fluctuations seamlessly. Artificial intelligence offers the dexterity required to adjust with minimal disruption.

Elastic logistics extends its reach to variables like sailing schedules, carrier space, container usage, and route optimization. This flexibility is a sturdy shield against the tides of overstocking and underutilized vessel space, bestowing businesses with stability and a competitive edge.

The IoT Revolution

Beyond blockchain, the rise of IoT devices is revolutionizing the visibility of supply chains. From the wings of airplanes to the wheels of trucks, video analytics provides real-time updates on shipping and delivery. IoT in warehouses and retail outlets is amplifying visibility across production, inventory management, and predictive maintenance. These real-time insights pave the way for proactive customer service, minimal downtime, and an overall hike in supply chain efficiency.

By integrating IoT data with business intelligence software, companies are endowed with the gift of data-driven decisions. Such integrations enable companies to make informed choices in their supply chain strategies.

The Overture to Transparency and Visibility

Consumer concerns regarding the impact of modern business on society have catalysed the demand for increased transparency. Companies are now stepping into the spotlight, shedding light on the sustainability of their supply chains and efforts to reduce their carbon footprint. The journey, however, is not yet complete. Further transparency regarding the supply chain’s impact on various facets of society is imperative.

A paradigm shift in global trade practices may usher in mandatory corporate disclosures related to various supply chain practices. Companies will have to offer insights into the impact of their supply chains on areas such as job creation, sourcing practices, labour types, and transportation modes. Disclosing this data will not only enhance brand image but also ensure regulatory compliance.

Maintaining transparency and readiness in the face of supply chain disruptions is the hallmark of a resilient, forward-thinking supply chain.

As we venture further into 2024, the supply chain landscape is brimming with transformation. Elastic logistics, the IoT revolution, transparency, and visibility are set to be the cornerstones of the new era. The path to success lies in embracing these changes and adapting to thrive in a dynamic and ever-evolving market.