In this erratic & unpredictable economic climate, it is crucial to increase warehouse productivity as much as its critical to reduce warehouse costs. Maximizing business profits takes a well-planned strategy as the competition is high. Reducing the warehouse cost is essential for survival but at the same time, it is important to maintain the quality & customer service.

Warehouse cost differs on the bases of the facility type, storage space & services provided. The major warehouse costs include handling of inventory, operations management, and general management expenses. The efficient management of the warehouse is the pulse of a supply chain. Warehouses are facing increasing challenges of labor shortages, pandemic issues, and changing market conditions, making warehouse management a complex task.

How to Reduce Warehouse Costs?

Reducing the costs is one of the most important aspects to manage a warehouse successfully. Several factors help to reduce overall warehouse costs. The most important among them are:

- Reduce required space by optimizing storage

- Protect inventory by efficient inventory control

- Reduce labor costs by effective workforce management

- Reduce equipment cost by proper use of equipment

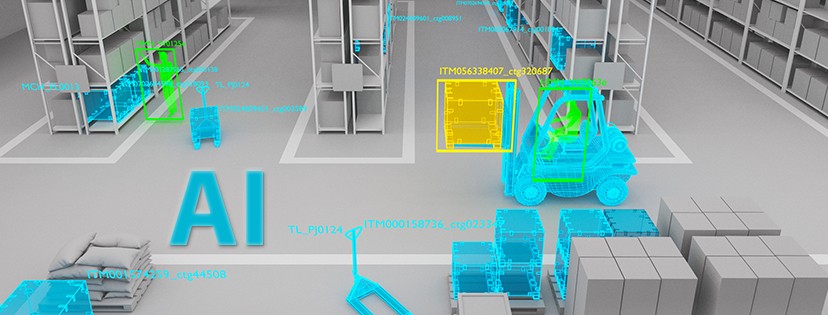

To help in successfully performing all these operations, companies need to embrace the digital revolution to ensure their business thrives and not just strives. Organizations need to focus on strengthening supply chain & logistics capacity, thus reducing warehouse costs. Leveraging AI for warehouse operations can be an effective way of doing that. Technology is the main factor controlling warehouse costs. An AI-based warehouse has several automated systems that improve efficiency, reduce errors, and save money. One of the many technologies in the field of AI is machine learning, which is the core of data analytics algorithms that power smart and modern warehouses. When used properly, machine learning in warehouse management can help in scalability & cost saving.

Storage Optimization

Efficient use of space is a critical issue in warehousing today. Poorly planned warehouse layout is a cause of plenty of warehouse accidents. Insufficient storage space or inefficient use of available spaces is the common problems of warehouses with a poor layout.

Automated systems like empty space detection show the floor & vertical space available for use. Also, object detection & tracking ensures the highest-selling inventory is easily accessible. Employing forklifts allows maximum utilization of available space.

Inventory Accuracy

Inventory in a warehouse should always be stored in properly identified areas. Accuracy & efficiency in handling inventory can lead to problems such as maintaining improper stock levels & build-ups of obsolete inventory. Lowered productivity, increased expenses & lost revenue are other impacts of inaccurate inventory.

AI-based automated systems like object detection, automatic packet counting, Bar code reading, logo detection, etc., offer real-time, accurate information about stock levels & compositions. Employing technology in inventory management can improve accuracy & reduce cost & time. RFID portals installed at strategic points automatically identify & track inventory as it enters & exits the warehouse, making it easier to locate a specific product, thus reducing costs due to lost or misplaced goods.

Labor Cost

An excellent warehouse manager is expected to increase productivity while minimizing labor costs. It is a balancing act for many warehouse managers. Generally, warehouses use expensive equipment & employ large labor forces from cleaners & packers to managers & administrators.

AI-based solutions are the lower-cost alternatives to human labor. AI can automate labor-intensive processes, thus reducing labor costs while improving quality. Automated systems can take on repetitive manual tasks ensuring that employees can focus on more important strategic tasks.

Preventive Maintenance to Reduce Warehouse Costs

Preventive maintenance is the prediction of potential machine failures in the factory by analyzing real-time data. Material degradation or corrosion is a very common problem for manufacturing processes that happen at the special temperature & environmental conditions. The result of this is the deformation of equipment. If not identified early, this can lead to major losses. For this reason, preventive maintenance is used for equipment monitoring.

Preventive maintenance is condition-based maintenance that monitors the equipment using sensor devices. These sensor systems provide data in real-time, which helps in making predictions when an asset requires maintenance, thus preventing equipment failure. Computer vision monitors equipment constantly based on different metrics. In case of any deviation from metrics, the sensors send an alert instantly to carry out maintenance activities.

Curb Theft & Loss for Cost Reduction

Another way in which AI can ensure smooth warehouse operations with reduced cost is by ensuring security & preventing loss. A warehouse is a large space & keeping track of every activity manually is a time & money-consuming task. Several AI-based solutions can ensure improved security & employee safety.

Automatic Number Plate Recognition (ANPR) system can track the authorized & unauthorized vehicle that enters or exits the premises in real-time and send instant alerts in case of intrusions.

Theft by humans within the premises can be controlled through Facial Recognition, Biometric Systems or Cross Line Detection. These systems can identify & track authorized employees in real-time. AI-based fire sensors can help to save a lot in content and structural damage by identifying fires at an early stage.

AI-technology systems help in intrusion detection to automatically identify any dangerous situation. Computer vision-based systems allow people to count and detect anomalies in movements, and crowd behavior analysis in real-time.

Final Words

Identify where & what type of cost-reducing measures is required the most in your set-up. AI is rapidly affecting the way modern warehouses perform their day-to-day operations & make long-term strategies. An integrated warehouse management system (WMS) can significantly be beneficial for your business to reach the desired objectives. AI-based intelligent warehouse solutions are helping organizations to improve operations & reduce costs by creating more efficient, flexible, and faster systems.

Want to improve warehousing operations & reduce warehousing costs without sacrificing the quality? Contact our experts & learn how you can run a more efficient & sustainable warehouse by leveraging our AI-based solutions into your present infrastructure.