With intelligent automation solutions, computer vision applications in industrial manufacturing has revolutionized the manufacturing process and workflow. As part of Industry 4.0, the upcoming manufacturing revolution, the manufacturing sector has been using a variety of automation technologies. The manufacturing sector is implementing a variety of cutting-edge technologies as part of industrial automation to revolutionize the way products are created, including artificial intelligence (AI), machine learning (ML), the internet of things (IoT), computer vision, robotics, and more.

How Computer Vision Applications Modernize Industrial Manufacturing

The modernization of the industrial manufacturing has seen the need for Computer Vision Applications in Manufacturing which provides Computer Vision Solutions for Manufacturing.

Let’s see how it provides assistance:

1. Root Causing

What can be better than a production and assembly lines that have every step captured on video while a product is being built? Computer vision applications makes it possible. Root causing captures the building process of a product on video to take any serial number and carefully review what went wrong (not by a person but an AI algorithm) during the production of the flawed product and get help from real-time alerts in case of any anomaly to eliminate damages, defects and disruptions.

2. Product Assembly

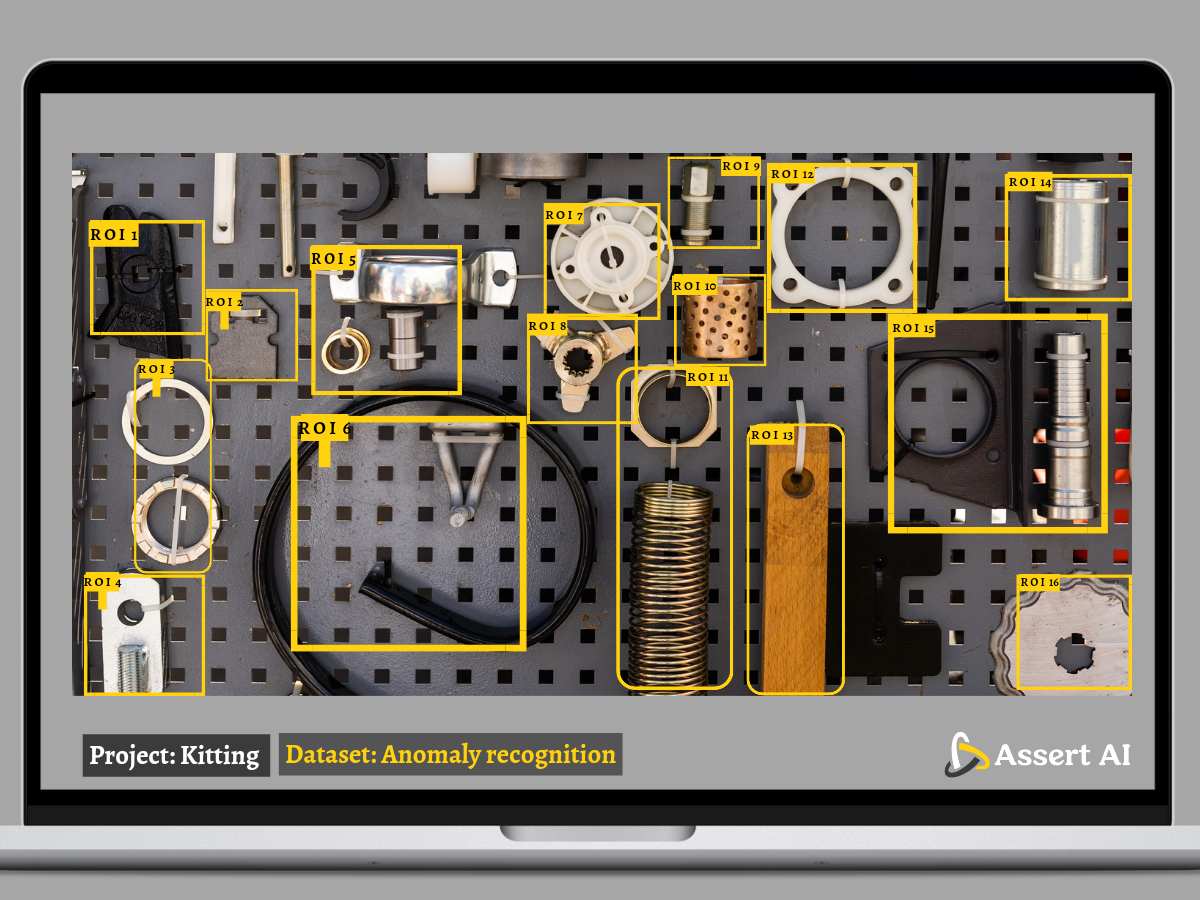

Part Kitting

The increasing influence of automation in the manufacturing sector is clear to see. The procedures involved in product assembly benefit from the usage of Computer Vision Applications in Manufacturing industries. To increase production rates, almost every industrial behemoth you are aware of is employing automated product assembly lines. The 3D model designs are produced using computer vision utilizing particular software. It enables the system to carry out the assembly procedures precisely. To maintain effective product assembly operations, it also helps to continuously monitor the automatic machines and people. By giving workers instructions and keeping track of their progress to ensure that all steps are taken, it also helps manual assembly operations. Additionally, by adhering to strict evaluation criteria, CV may help you prevent circumstances that could result in product recalls, thereby guaranteeing better product quality and therein, higher customer satisfaction.

3. Defect Protection

Production lines sometimes fall short of detecting all current or potential flaws in the manufacturing processes with 100% accuracy. Both the makers and the customers may suffer losses as a result of these flaws. Additionally, it can raise client unhappiness, which might be catastrophic for the company. Computer Vision Solutions for Manufacturing includes identifying both macro and micro level production line flaws with real-time alerts for correction and actionable insights. Industries can make their manufacturing lines defect-free by investing in computer vision-based detect detection toolkit. AI-based computer vision systems can assist using algorithms that can detect, identify, classify defects and anomalies in real-time and trigger instant alerts and notifications.

4. Personnel And Equipment Safety

One of the top priorities for manufacturing facilities around the world is personnel and equipment safety. AI-powered computer vision systems can aid in lowering the likelihood of any unpleasant mishaps in fields where employees work in hazardous environments. The method of having a team member sit and watch the screens to keep track of activity at the office is error-prone. To prevent mishaps, machine vision can assist and make sure that the right security and safety procedures are followed at the workstations. Even if an accident does occur, computer vision aids management in determining its position and severity. The right steps should be taken to ensure the equipment and personnel safety with the help of PPE Detection, Fire & Smoke Detection, equipment monitoring, cycle count etc.

5. Automating Quality Control

Many outstanding developments in industrial automation can be attributed to machine vision. The area of quality control is one of the most notable accomplishments. Because of their increased productivity, improved manufacturing process accuracy, and decreased operational costs, CV-based automated systems are a valuable addition to inspection operations. They provide an excellent option for quality and process control. A camera aimed at a production line takes pictures that are subsequently captured by a CV-based automated system and compared algorithmically to a predefined image to identify defective items. The application is widely used for flaw identification, geometric inspection, packing control, product categorization, surface finish inspection, colour and texture analysis, etc.

Also read:

Reduce Warehouse Costs During Erratic Economic Climate

Wrapping Up

Computer Vision Solutions for Manufacturing include automated sorting, counting, inspection during manufacturing and packaging. Computer Vision Applications in Manufacturing decrease human involvement, maximize operational effectiveness, and cut labor expenses. Machine Vision examinations, which enable objective non-contact evaluation, are particularly well suited to the industrial setting.