Computer vision has indeed been influential in computerizing quality control due to its capability to locate, recognize, and examine product lines using algorithmic imaging techniques.

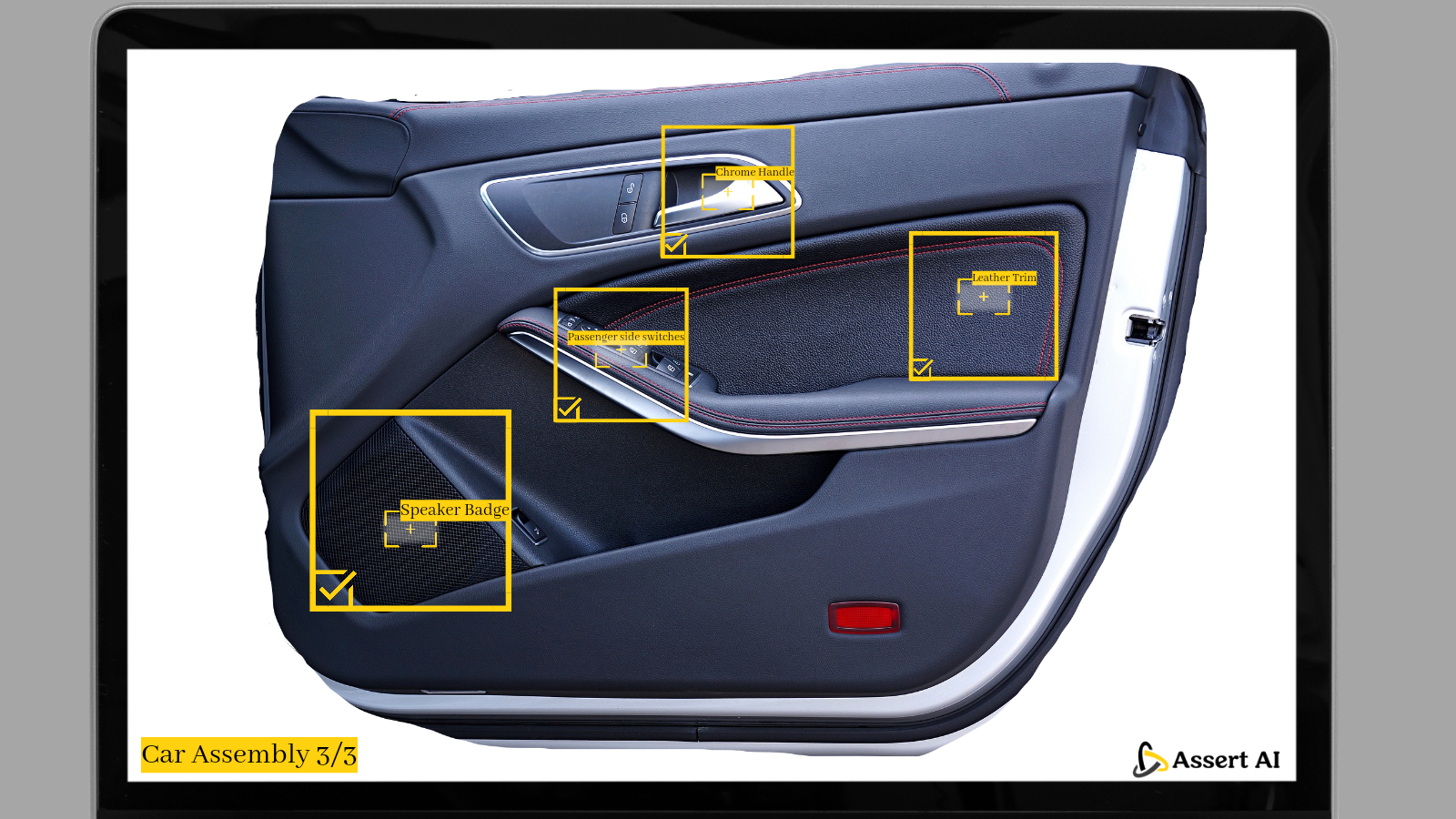

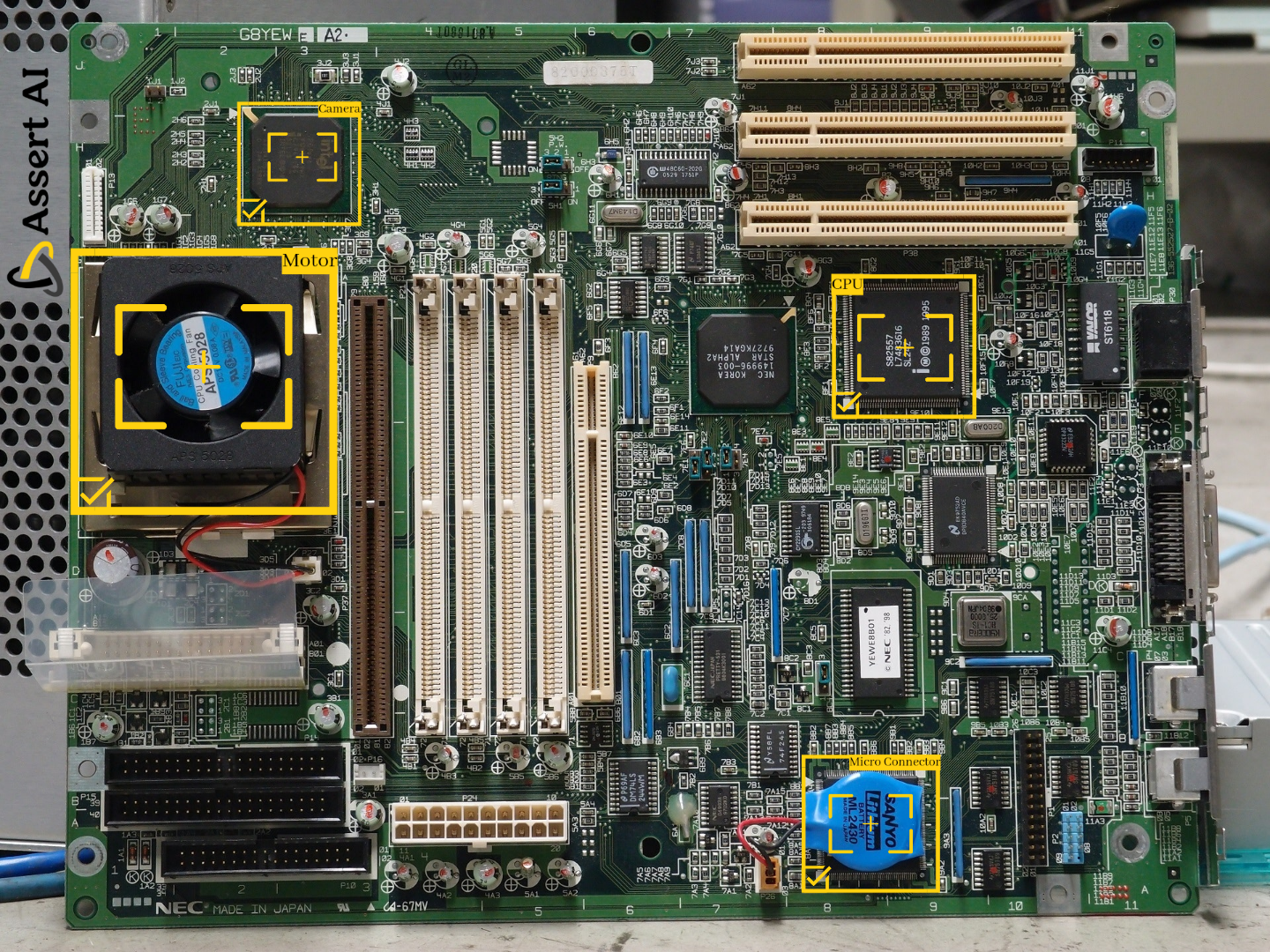

However, traditional algorithmic image processing has limitations that have typically restricted computer vision applications to component inspections. When the element is part of a bigger assembly, complex package, or kit, such as an automotive assembly, circuit board, or surgical kit, random product placement, lighting variations, as well as other variables can overpower the computations of traditional computer vision systems. As a result, final assembly, package, and kit inspection have remained largely a manual operation.

However, with the advent of technology and raised efficiency of computer vision, the entire process of manufacturing and its complex areas have been taken care of and entirely automated, part kitting being one of them.

What Is Kitting

Kitting is the process of selecting and conveying all of the components needed for the assembly of a specific product. Kitting is frequently done inside a production plant, in a cell separate from the basic production line, or by third-party logistics partners.

As previously stated, kitting in manufacturing is best advised whenever a product requires a large number of small parts. In other cases, the process is ideal for manufacturers who have a limited floor area for stacking required parts.

Additionally, kitting is useful when a manufacturing company creates customized products for its clients. For example, when generating a custom product that necessitates different-colored components or parts with different specifications, kitting is ideal.

Role of Computer Vision in Production Line and Kitting

Computer vision can help with accurate product assembly and reduce the time it takes to finish a product build. When trying to deal with fragile items or portions that cannot be easily maneuvered manually, computer vision provides superpowers to assembly line machinery.

With computer vision, manufacturing processes can be finished markedly more quickly and effectively because kitting offers all necessary components to the controller in control of the assembly. This is because workers do not have to search the production plant and storage area for specific product components. Instead, operators are given all they require in a solitary kit at their work area, enabling them to spend more hours on the actual assembly.

Additionally, kitting software automates data collection and aids in the tracking of all items used in manufacturing, making it necessary for producers who require evidence of traceability for compliance reasons.

The Work Process of AI Integrated Kitting

Due to rising consumer demand and expectations, packaging and kitting companies require the highest levels of accuracy and efficiency. However, the most significant impact of packaging and kitting errors is the cost implication. For many businesses, the most damaging outcome is downtime. This manifests as both opportunity cost and the production of additional parts. In some cases, these costs can amount to millions of dollars per shift.

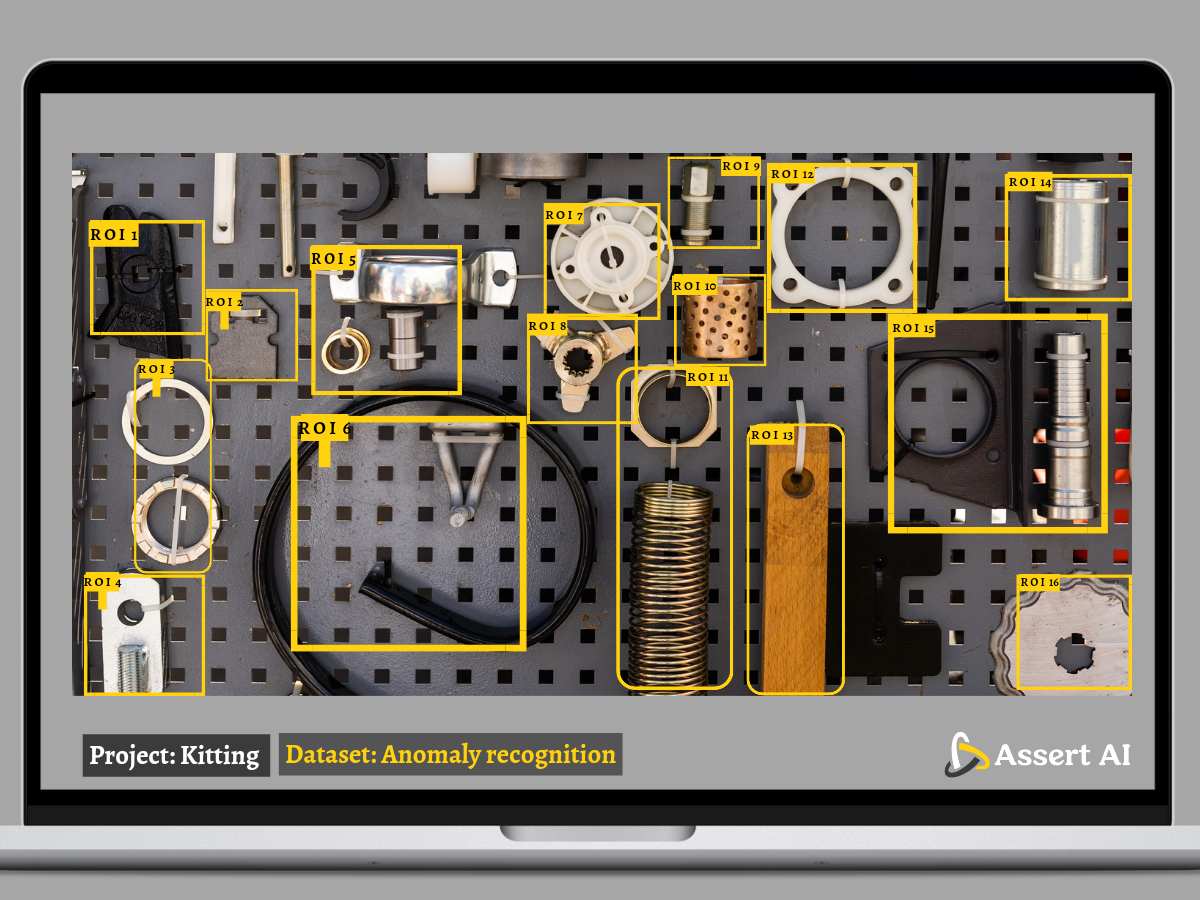

The kitting workstation now has a CCTV camera. Every possible “kit” has its anomaly model. A fixture is used to ensure that parts are in secure locations. By scanning a barcode on the kitting container, the operator tells the system which kit they are pulling for and the barcode indicates which kit is being built and what parts are to be expected.

When parts are missing or incorrectly placed in the kit, an error message is sent to an HMI via Modbus TCP via a PLC to alert the operator to double-check their work. In this case, a model must be created for each possible kit variant, which, while technically possible, requires a large amount of data. Multiple regions of interest (ROIs) are used to simplify model building and provide better quality metrics, building on the basic implementation. Each area of the kitting fixture can have its ROI.

All this makes model construction easier. Every possible part variant must be trained on each Region of Interest. However, rather than having to build a model for each kit, kits can be created by selecting the relevant parts from each model. Furthermore, rather than simply indicating that the kit is incorrect, the specific part that is incorrect can be identified using a multi-ROI inspection.

Conclusion

Because demand for some consumer goods is declining, manufacturers are slowing production and reducing the number of operators on the floor. Many people believe that now is a good time to start prototyping to better solve this problem when they ramp up again. The inspection game has changed thanks to AI in industrial kitting.