Potential Causes of Forklift Accident

Accidents Forklift accidents can occur due to various reasons, including operator error, limited visibility, crowded workspaces, and distracted driving. These incidents can have a profound impact on both your employees and your business. With FAPS, we address these causes head-on by leveraging advanced computer vision algorithms that provide real-time monitoring and instant alerts, significantly reducing the risk of accidents.

Operator error

Improper use of controls, or failure to follow safety protocols

Limited visibility

Blind spots, obstructed views, or poor lighting conditions.

Congested Workspaces

Overcrowded areas, narrow aisles, or obstructions that impede safe maneuvering.

Distracted driving

Use of mobile devices, talking to colleagues, or engaging in other activities while operating the forklift.

Inadequate Maintenance

Malfunctioning safety features, or worn-out tires that increase the risk of accidents.

Lack of communication

Insufficient communication between forklift operators and other workers, leading to collisions or other accidents.

Overspeeding

Operating the forklift at excessive speeds or disregarding safety guidelines.

Improper Loading

Incorrectly loaded or unbalanced loads that can cause the forklift to tip over or lose stability.

Environmental Factors

Slippery surfaces, uneven terrain, or adverse weather conditions that affect forklift operation.

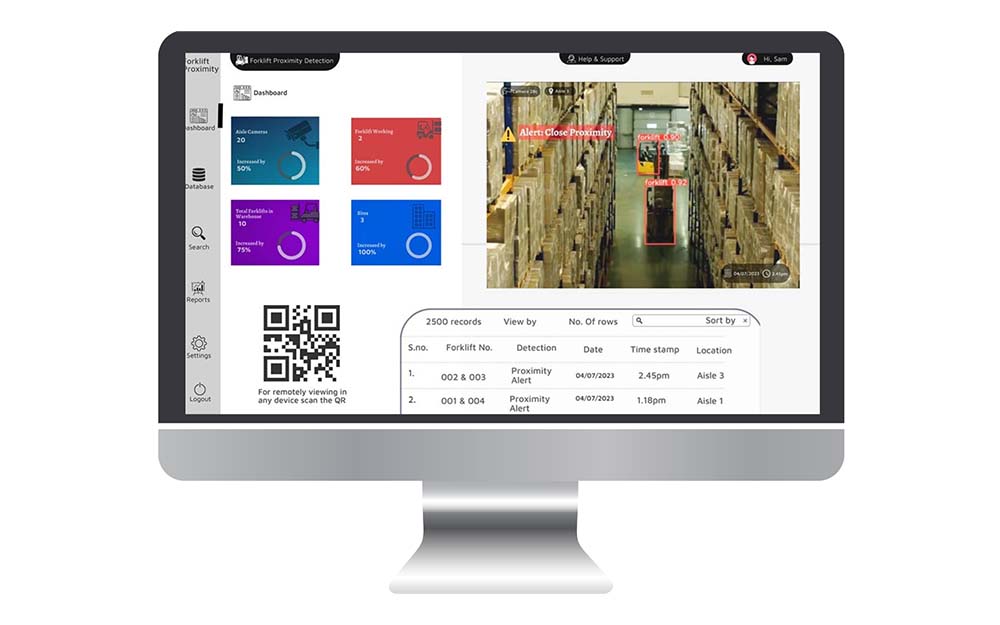

By harnessing the power of computer vision technology, Forklift Accident Prevention Systems (FAPS) effectively mitigate the risk factors leading to forklift accidents by providing continuous real-time monitoring, timely alerts, and operator guidance. This advanced solution enhances situational awareness, promotes responsible operator behavior, and ultimately fosters a safer work environment.