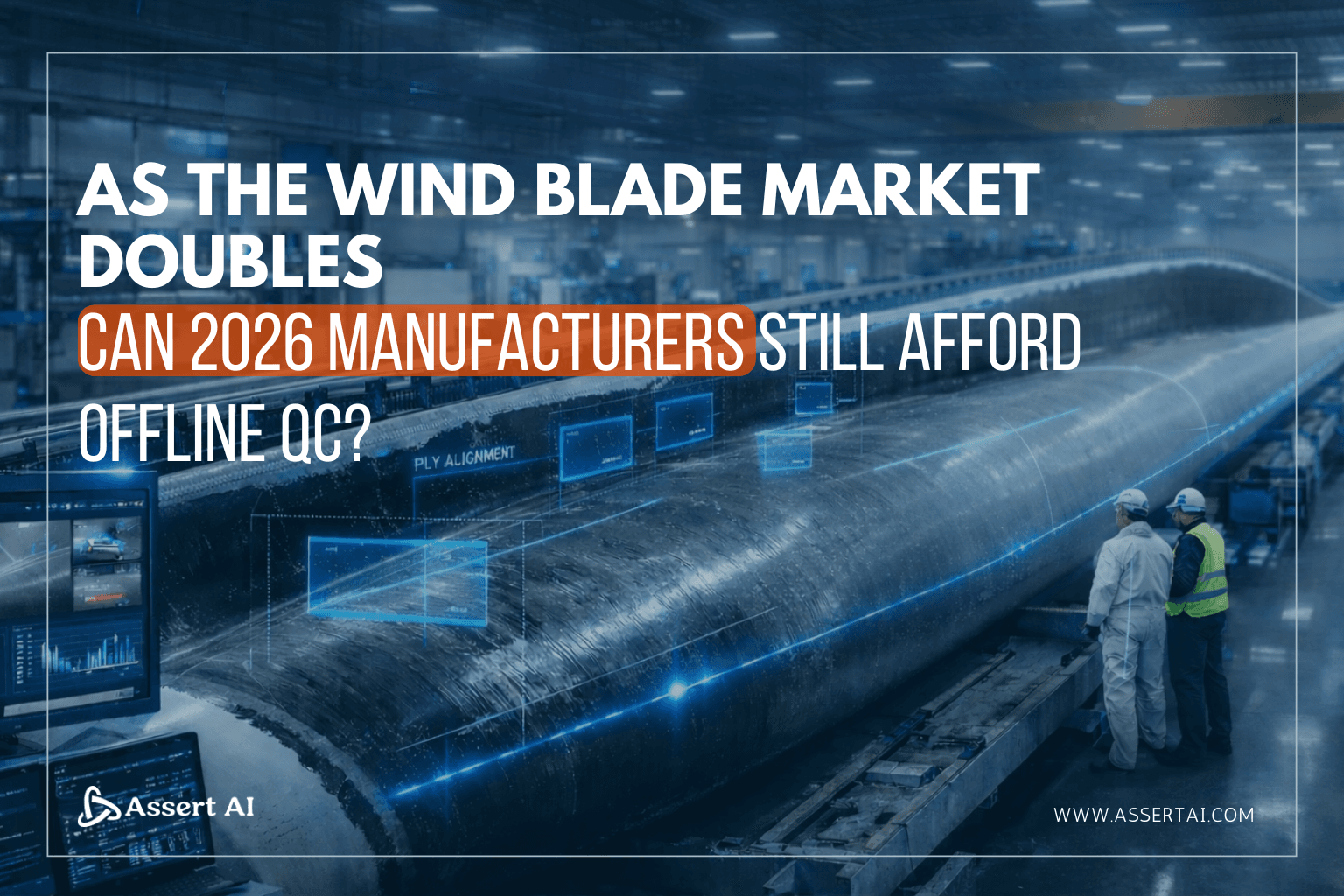

Wind turbine blades are designed to last decades, harnessing the raw force of wind into renewable power. But hidden inside their composite shells lies a fragile truth: a single misstep in the ply layup process can compromise an entire blade.

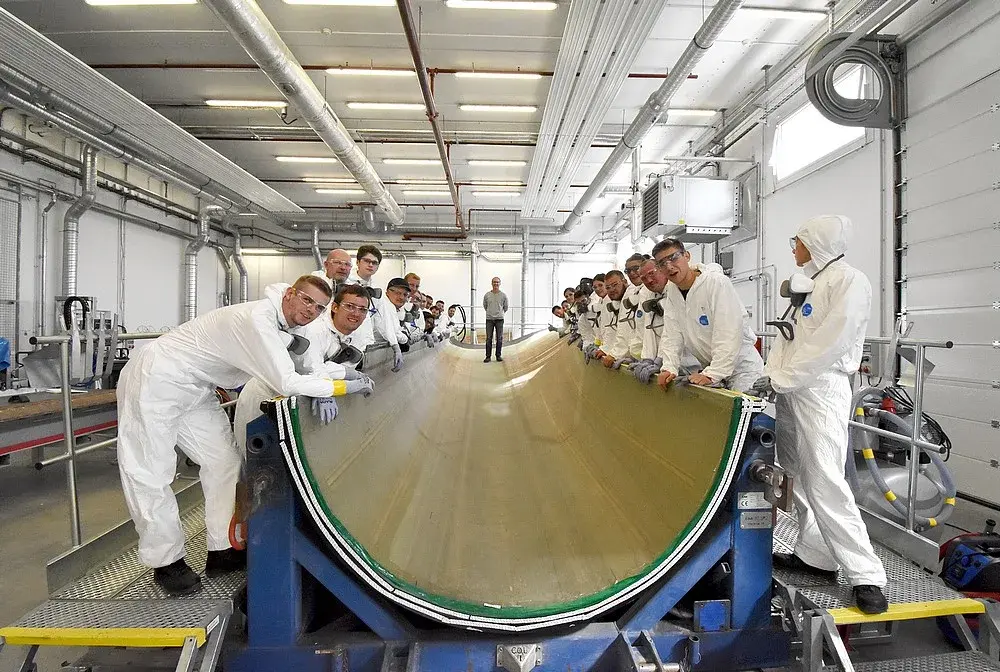

The ply layup process is one of the most delicate and labor-intensive stages of manufacturing. It’s here that layers of fiberglass or carbon fiber are meticulously placed and bonded with resin. Done right, layup produces a strong, lightweight structure capable of enduring 20–25 years of service. Done wrong, it plants time bombs of weakness that may not explode until years later when failures cost millions.

The Layup Problem

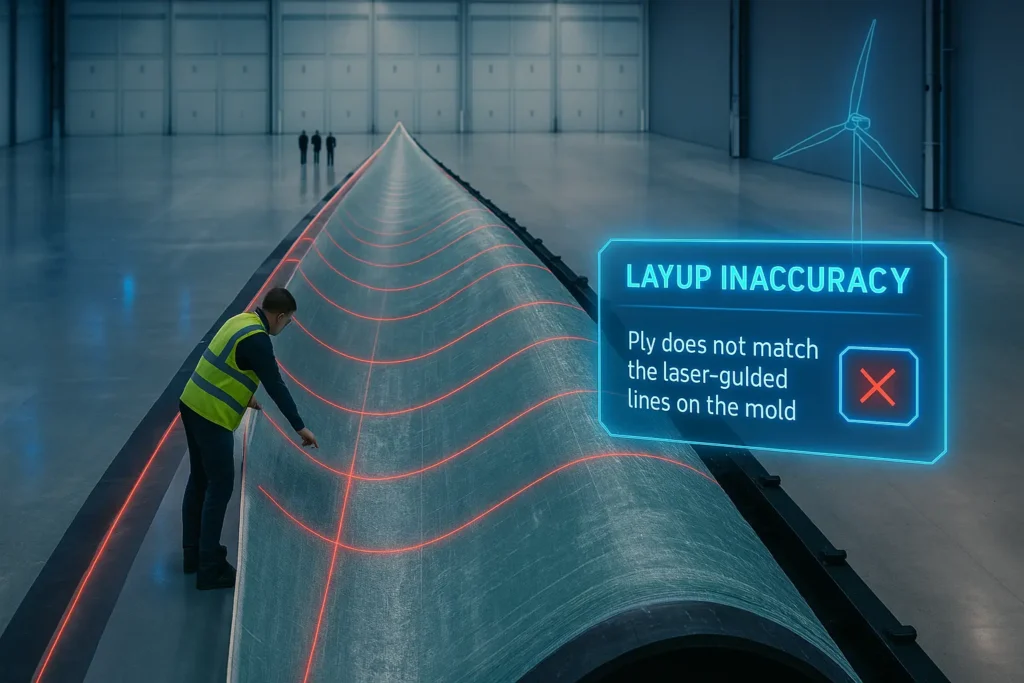

Invisible Errors

Tiny voids, wrinkles, air bubbles, or misaligned fibers often escape manual detection. While invisible at the factory, these flaws can evolve into micro-cracks, delamination, or localized stress points, drastically reducing blade strength.

Human Dependence

Despite advances in automation, layup remains a manual, precision-heavy task. Workers must handle large fiber sheets under time pressure and varying conditions. Fatigue, rushing, or inconsistent inspection practices create opportunities for defects to creep in. Even well-trained teams are vulnerable to unintentional human error, which remains one of the most persistent sources of quality risk.

SOP Deviations in Ply Layup

In practice, operators sometimes stack multiple plies of different types together, bypassing standard operating procedures and guided dimensions. While some factories still rely on manual logs and others deploy laser projection systems for assistance, in both environments deviations occur. Workers often unaware of the downstream impact, may treat these steps as routine, but every overlooked guideline carries weight. What seems like a shortcut on the factory floor can translate into multimillion-dollar risks: premature blade failures, unplanned farm downtime, and even safety hazards for communities if a blade fractures in operation.

Costly Consequences

Even “minor” layup defects can cut blade lifespan by years. Premature blade replacements cost $200,000 or more each for onshore turbines and far higher for offshore, where logistics, vessels, and cranes push replacement costs into the half-million dollar range.

According to ABJ Drones field data, micro-cracks are among the most common early failure modes, and many can be traced back to layup inconsistencies. In short: what seems like a small oversight during production often leads to catastrophic losses in the field.

Why Traditional QA Falls Short

Blade manufacturers already deploy multiple quality checks but the layup stage still slips through the cracks.

Visual Inspections: Skilled inspectors can spot major wrinkles or resin-rich areas, but subtle fiber shifts or micro-voids are almost impossible to see.

Destructive Testing: Pulling samples or testing sacrificial blades can reveal defects but only after costly materials have already been wasted.

Manual NDT (Ultrasound, Thermography): These techniques are accurate, but they’re slow, expensive, and difficult to scale across full-size blades stretching 80–120 meters.

The result? Layup remains one of the biggest blind spots in blade quality assurance. A flaw at this stage often goes undetected until it’s too late.

Why Layup Matters More Than Ever?

With global wind capacity projected to triple by 2030 (IEA), blade manufacturing is scaling at unprecedented speed. Larger blades some longer than a football field are being produced under tighter timelines and higher demand.

This growth amplifies the risks:

- Larger blades mean more material and more chances for defects.

- Speed-to-market pressures increase the likelihood of rushed layups.

- Warranty claims and recalls can run into hundreds of millions of dollars, as seen in recent high-profile blade failures from leading OEMs.

A single missed defect at layup can ripple into global supply chain delays, financial hits, and reputational damage.

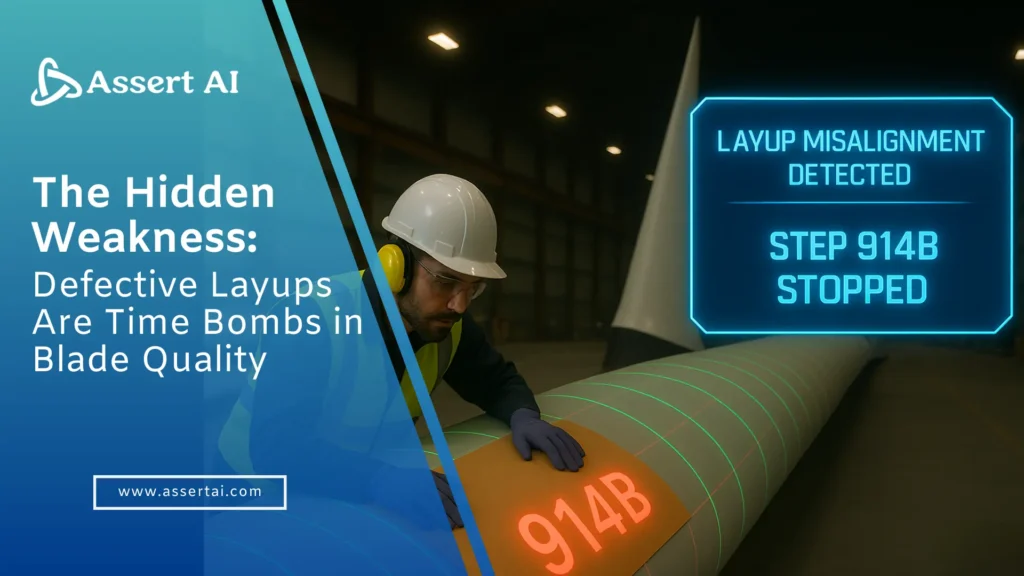

ORBIT: Embedding Precision into Layup

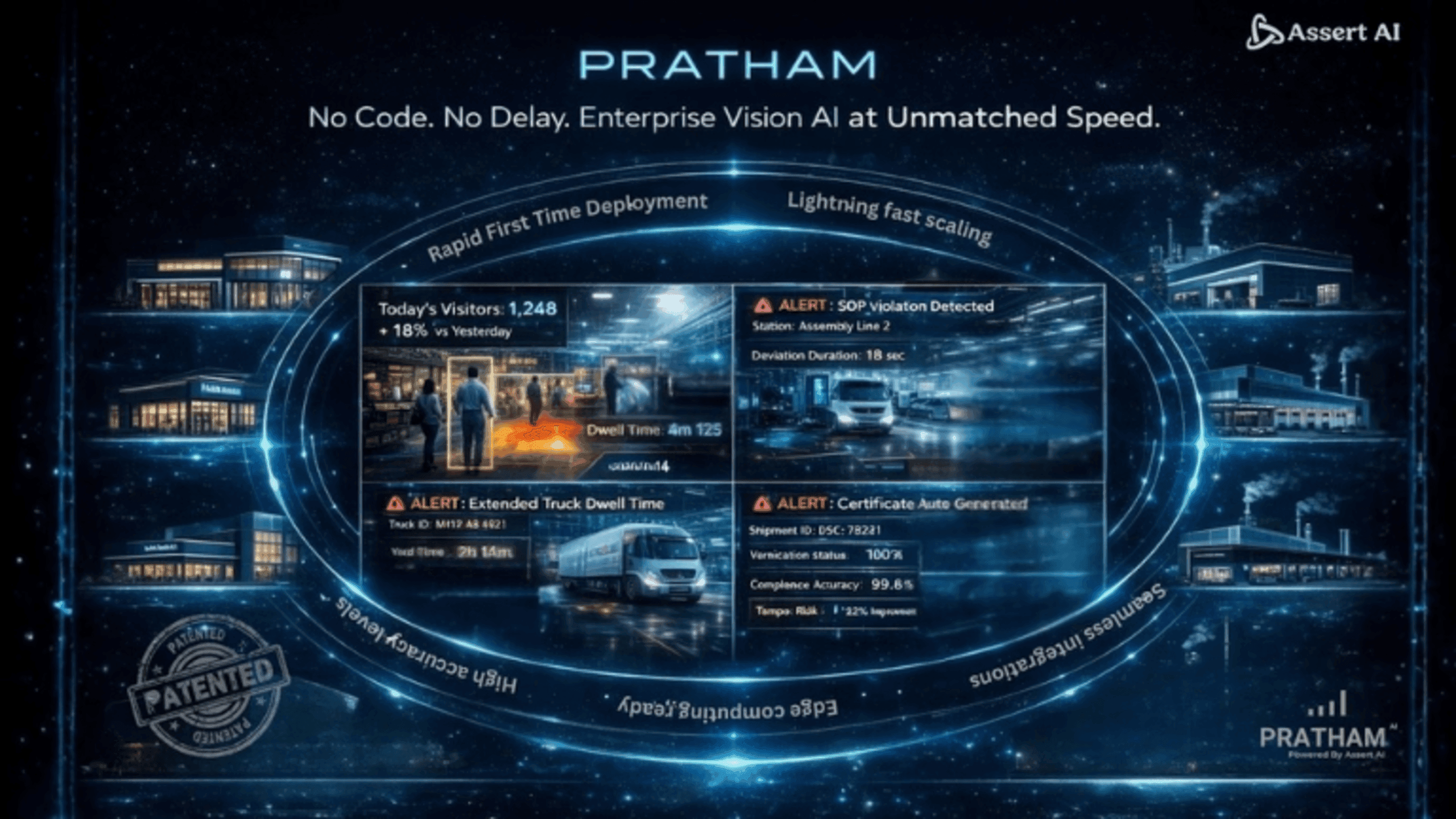

This is where ORBIT changes the game. By embedding AI and computer vision into the manufacturing floor, ORBIT ensures real-time layup quality control.

- High-Resolution Monitoring

ORBIT continuously scans ply placement, adhesive bonding, and curing stages. Subtle irregularities imperceptible to human eyes are flagged instantly.

- Anomaly Detection Algorithms

Machine learning models, trained on thousands of defect images, catch early signs of voids, wrinkles, or fiber misalignment. ORBIT doesn’t just detect what’s obvious it predicts patterns of failure before they escalate.

- Process Consistency

Every blade is monitored under the same exacting standards, eliminating the variability of manual inspection and ensuring repeatable, reliable quality.

- Data Feedback Loop

Each detected anomaly is logged into ORBIT’s defect intelligence library. Over time, this data improves not only immediate production but also informs better layup design, training, and process optimization.

- Reduced Failures, Longer Life

By intervening early, ORBIT ensures that blades deliver their full 20–25 year design lifespan. The impact is measurable: fewer warranty claims, reduced scrap rates, and dramatically lower risk of field failures.

The difference? Where traditional QA patches problems after the fact, ORBIT prevents them before they exist.

Turning Layup Blind Spots into Quality Benchmarks

The future of wind energy depends on producing more blades, also on producing better blades that deliver on their promise of long life and reliable performance. Layup, though hidden inside every blade, is where much of that promise is won or lost.

ORBIT brings unprecedented precision to this critical stage, transforming it from a blind spot into a benchmark of quality.

When a Wind Blade Fails: The Hidden Six-Figure Toll You Never Saw Coming

The Real Environmental Cost: Wind Blade Waste Is Undercutting “Clean Energy”

Resilience Begins in Manufacturing

Layup failures may begin in the shadows, but their costs are impossible to hide measured in dollars, downtime, and damaged trust.

With ORBIT, manufacturers build blades on a foundation of consistency, strength, and proactive assurance.

Don’t let defective layups become ticking time bombs. ORBIT ensures your production line builds strength, not hidden weaknesses.