Because safety isn’t just about hard hats and hope.

Why Are We Talking About Safety?

Let’s get real for a second.

One loose bolt. One distracted moment. One “I’ll just skip the helmet this time.”

That’s all it takes to flip your factory floor from a place of productivity to a scene from an accident investigation video.

In the world of manufacturing, safety isn’t just a checklist, it’s a lifeline. It saves lives, prevents losses, and boosts efficiency like nothing else.

But here’s the kicker: Traditional safety protocols? They’re often reactive. And in safety, reactive is already too late.

Say hello to real-time safety monitoring. It’s like giving your facility eyes, brains, and lightning-fast reflexes minus the coffee breaks.

The Safety Pyramid: A Proven Predictive Model

Heinrich’s Safety Pyramid is a statistically validated model demonstrating the correlation between unsafe acts and severe incidents.

What This Pyramid Tells Us?

Prevention starts at the bottom.

Addressing 3,00,000 unsafe acts can prevent:

✅ 30,000 near misses

✅ 300 minor injuries

✅ 30 serious injuries

✅ And potentially 1 fatality

Root causes are often ignored because they:

- Depend on shared understanding

- Are hard to quantify

- Need extensive training to correct

- Aren’t always backed by data

Yet, they are the leading indicators of future high-severity events. Identifying and addressing them early is critical for any data-driven safety strategy.

Near Misses: The Almost-Accidents That Matter Most

So what exactly is a near miss?

Think of it like this: You almost stepped on a banana peel but caught yourself just in time. No injury, but still… pretty close, right?

In manufacturing, a near miss might be:

- A forklift zooming past someone by inches

- A worker entering a restricted zone

- A machine malfunctioning without causing injury this time

These are golden moments of insight if you’re paying attention. And guess what? Most facilities aren’t.

Real-time safety monitoring flips the script. It captures these “almost” before they become “definitelys.” That’s how you stop accidents before they even happen.

Dive Into Real-Time Intelligence: Exploring the AI-Powered Dashboards

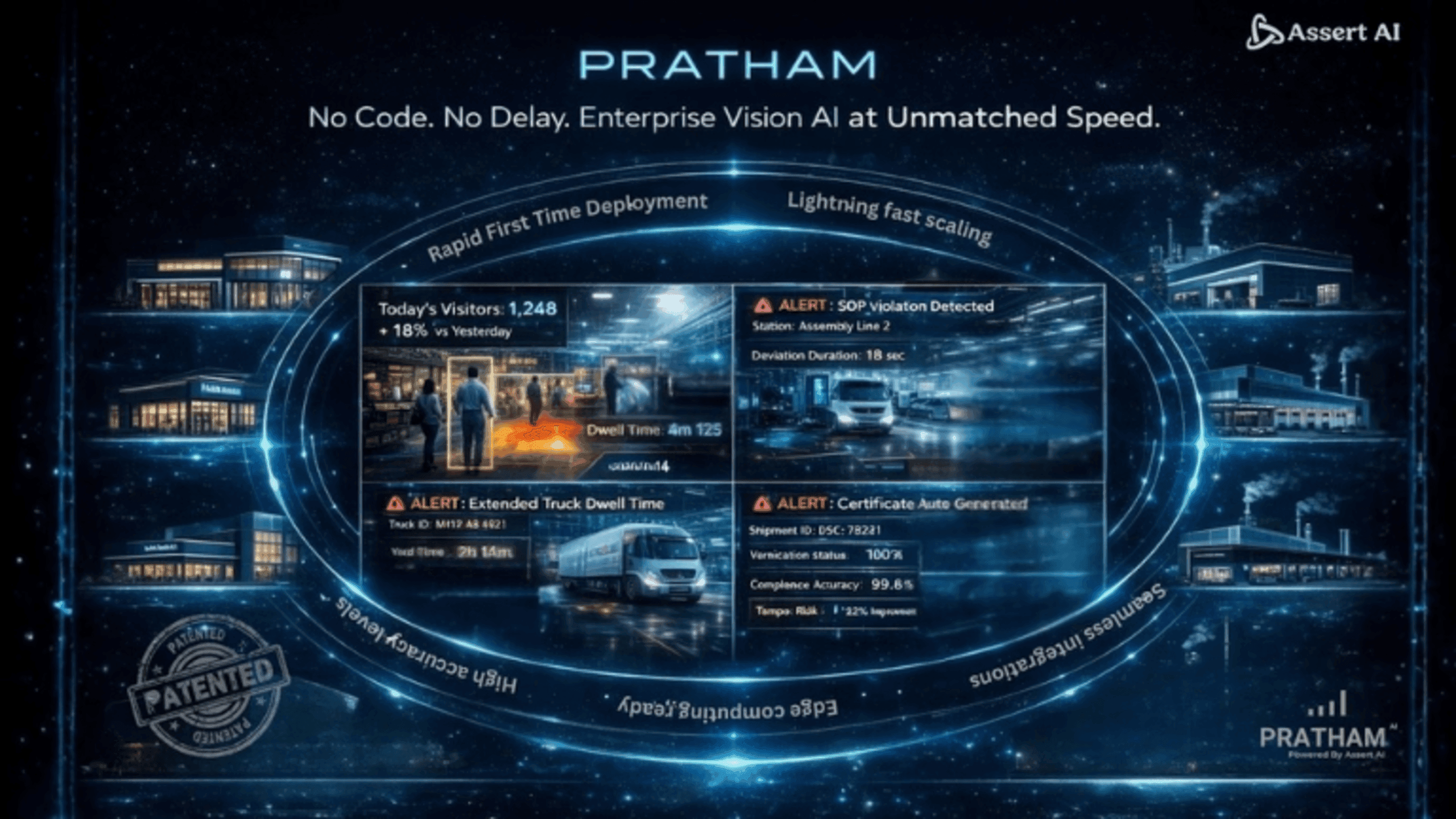

Ever wondered how powerful computer vision looks in action? These dashboard screenshots are your window into the heartbeat of Assert AI’s real-time monitoring system clear, visual, and packed with insights.

Each dashboard tells a story, a story of awareness, action, and advancement.

🛎️ Smart Alerts That Matter

Our AI engine doesn’t just detect issues; it alerts you instantly. Each dashboard panel showcases real-time alerts, whether it’s a missing helmet in a manufacturing zone, unauthorized entry in a restricted area, or a near miss with a forklift in a warehouse.

You’ll notice alert boxes and highlights that are color-coded and timestamped, so the moment something goes wrong, you’re in the know.

🧠 From Detection to Direction: The Solution Layer

What sets our platform apart is that it doesn’t just stop at identifying problems. Our AI dashboards recommend solutions. You’ll see panels suggesting the next best action, be it alerting the supervisor, locking an access point, or tagging an event for review. The system helps in smart guided decisions.

🔍 Find What Matters with Filters

With hundreds of events happening daily, the custom filter options help you zoom in on exactly what you need, by zone, time, alert type, camera ID, or even specific employees. Whether you’re in logistics or hospitality, filtering ensures your focus stays sharp and strategic.

📈 Visualize Insights with Graphs

Forget raw data dumps. Our AI translates complex data into easy-to-read graphs that help you monitor trends, like footfall variation across zones, PPE compliance over time, or truck turnaround rates at loading bays. It’s all visual, all real-time, and incredibly actionable.

📸 The Moment Captured

Each alert comes with image snapshots , a visual cue of the exact moment an incident occurred. These images are time-stamped and camera-identified, helping with audits, training, or escalation. It’s like having a visual diary of every event that matters.

✅ Alert Status and Closure Workflow

What happens after an alert is raised? That’s where our platform truly shines.

As seen in the screenshot, each alert comes with an “Alert Status” column, showing whether it’s open or closed. Once reviewed, the alert is updated with feedback from users (e.g., “Wear helmet for head protection”), and the name of the responder is logged for transparency. The status update timestamp ensures traceability and audit readiness. This complete lifecycle, from detection to feedback to closure, helps organizations close safety loops efficiently.

So What Should Your Real-Time Safety Dashboard Actually Track?

Think of your safety dashboard like a digital guardian, one that’s always watching, never judging, and constantly alerting you (in real-time!) when something goes off.

Here’s what the smartest manufacturing facilities are tracking:

🧤 PPE Compliance

Are your workers really wearing what they should? Real-time monitoring can track helmets, gloves, masks, safety vests, and all the critical gear. Non-compliance is a rule break; moreover it’s a risk multiplier. With computer vision, detect instantly who’s missing what and trigger alerts before the hazard escalates.

🚗 Vehicle Overspeeding

Speeding forklifts or other industrial vehicles inside your plant? Major red flag. Overspeed detection with real-time alerts can help reduce crash risks, protect workers in shared zones, and prevent costly equipment damage. It’s not just about speed limits, it’s about saving lives and logistics.

🦺 Forklift Near Miss

Forklifts are essential, but also among the most dangerous equipment in manufacturing and warehousing. Real-time vision can detect near misses with pedestrians, other forklifts, or infrastructure, so you can implement safety buffers and redesign movement paths before accidents happen.

🚫 Unauthorized Entry

Not all zones are for everyone. Whether it’s a restricted area, hazardous machine zone, or clean room, your dashboard should flag unauthorized access instantly. Real-time alerts can prevent safety breaches, IP theft, and liability nightmares in one click.

🛠️ Machine Near Miss

Near misses around industrial machines often go unreported. Real-time computer vision systems detect unsafe proximity, incorrect posture, or absence of safety guards, helping teams take corrective actions before someone gets caught in the wrong place at the wrong time.

🧱 Perimeter Intrusion

Your safety system should start before the first door. Detect intrusions at outer perimeters, construction boundaries, or fence lines with real-time video intelligence. This protects not just people, but your entire infrastructure from potential threats.

Dashboards That Actually Save Lives (Not Just Look Fancy)

Let’s talk about real outcomes.

One of our clients in heavy manufacturing saw a remarkable year-over-year improvement in safety compliance, with unauthorized entry alerts dropping by 96.8%, and helmet violations reducing by over 30%.

All major alert categories saw a double-digit or higher percentage reduction, signaling a strong positive impact of safety interventions and monitoring systems deployed in FY 2024–25.

Dashboards are no longer just colorful graphs for monthly reports. They’re action tools. They empower:

- Safety managers to act fast

- Floor supervisors to intervene early

- Executives to invest where it counts

Don’t Just React. Prevent.

Safety doesn’t begin with accidents. It begins way before, with the near misses, the subtle signs, the data blips you didn’t even know were important.

Real-time safety monitoring is your best shot at making sure everyone gets home safe.

So, what’s your dashboard saying right now?

Ready to See Safety Like Never Before?

Let’s build a solution together that aligns seamlessly with your facility’s safety SOPs. Let Assert AI show you how real-time safety monitoring can make your facility smarter, safer, and more productive.