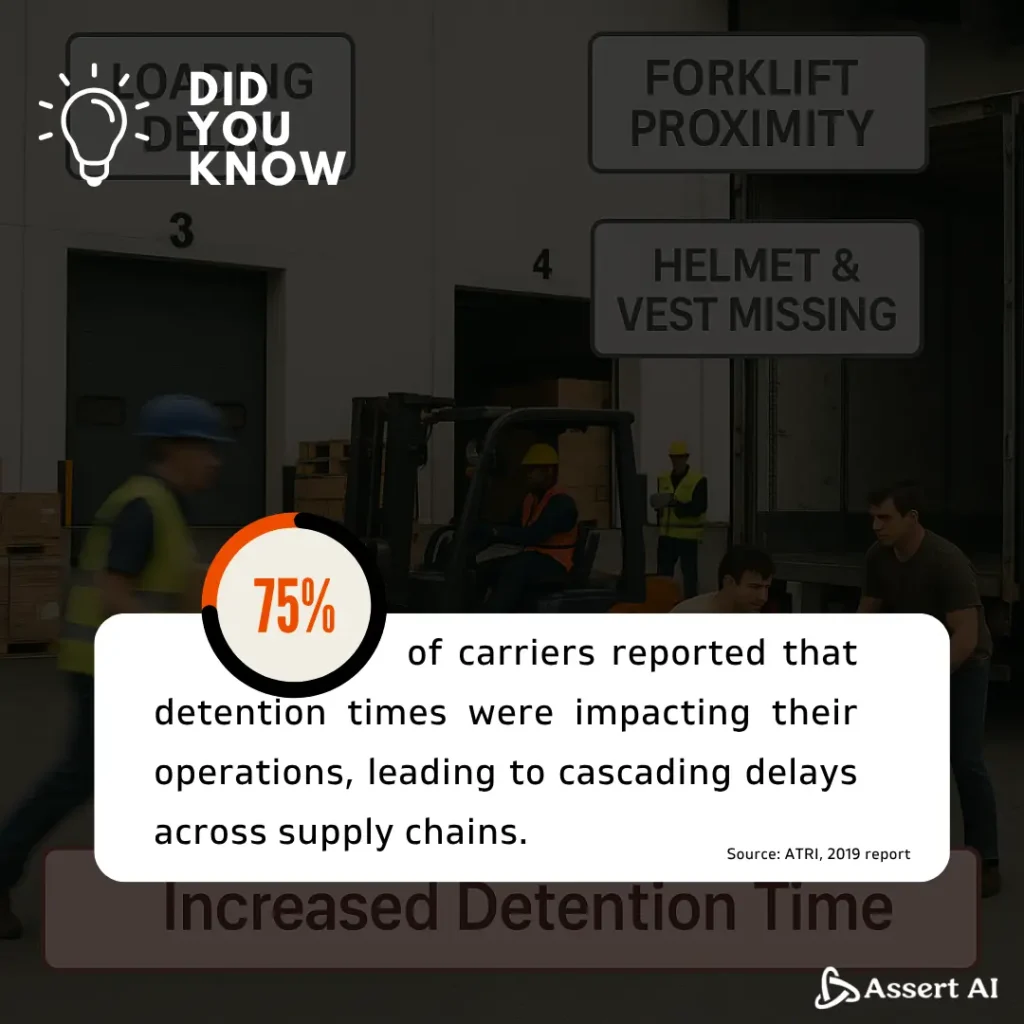

Nothing derails a busy day at the warehouse faster than detention and dock delays. They show up uninvited, overstay their welcome, and leave you 90-/*picking up the bill. And without real-time warehouse tracking, they’re nearly impossible to kick out.

For retailers and distribution center operators, detention fees and dock congestion don’t just cause headaches, they hurt bottom lines, impact relationships with transport partners, and reduce customer satisfaction due to delayed shipments.

Let’s break down why this happens and more importantly, how to fix it.

Why Dock Delays and Detention Happen (And Yes, It’s Often Internal)

Before we talk fixes, let’s be honest- many dock delays start inside the four walls of your own facility:

- Poor Planning and Scheduling

Without real-time warehouse tracking, trucks showing up late is one factor, but often it’s your schedule clashing with theirs, leading to delays. Last-minute slot changes, unclear appointments, or failing to stagger arrivals properly can throw the entire dock into disarray.

- Lack of Real-Time Visibility

When your team doesn’t have a live view of inbound trucks, dock availability, or staging areas, they’re left scrambling. Result? Idle docks, confused staff, and trucks waiting endlessly to be processed.

- Inefficient Resource Allocation

Dock doors might be available, but if there aren’t enough forklifts, pallet jacks, or trained personnel at the right time, unloading slows to a crawl. Busy periods often highlight these mismatches between workload and staffing.

- Paperwork Pile-Ups

Manual check-ins, misplaced documents, or outdated processes create bottlenecks. Even a small clerical mistake can snowball into half-hour holdups at the dock.

- Poor Internal Communication

If warehouse teams, supervisors, and yard staff aren’t synced, delays are inevitable. A dock might be clear, but if no one’s told the receiving team, or if the carrier isn’t notified, everyone ends up waiting.

Proven Strategies to Reduce Detention and Dock Delays

Here’s what retailers and distribution center leaders can do, starting today:

1. Smarter Appointment Scheduling

Work closely with carriers to implement a dock appointment system. Spread arrivals throughout the day and prioritize based on load criticality or dock availability.

Pro Tip: Use dynamic scheduling. If a dock clears early, notify waiting carriers instantly.

2. Real-Time Communication with Carriers

Ensure dispatch teams and carriers stay in constant communication through messaging apps or Transport Management Systems (TMS). Even 30 minutes of advance notice about delays, if not real-time tracking, can help reallocate dock staff or equipment.

3. Pre-Check Documentation Digitally

Where possible, shift to digital check-ins. Have drivers submit documentation before arriving, cutting down paperwork processing time at the gate.

4. Optimize Yard Management

It’s not just what’s happening at the dock, it’s the entire yard. A disorganized yard means trucks can’t find where they need to go, leading to wasted minutes or even hours.

Quick Win: Simple signage, trained marshals, or RFID-based gate passes can drastically reduce confusion.

5. Regular Data Review

If you don’t measure it, you can’t fix it. Review detention reports monthly. Where are the patterns? Which carriers are consistently late? Which docks are underperforming?

Let’s Do Better: Using Visual AI to Eliminate Blind Spots

If you’ve done all of the above and are still grappling with delays and bottlenecks, the missing piece might be real-time visibility into warehouse activities- not theoretical, but real, on-the-ground visibility.

That’s where Visual AI comes in.

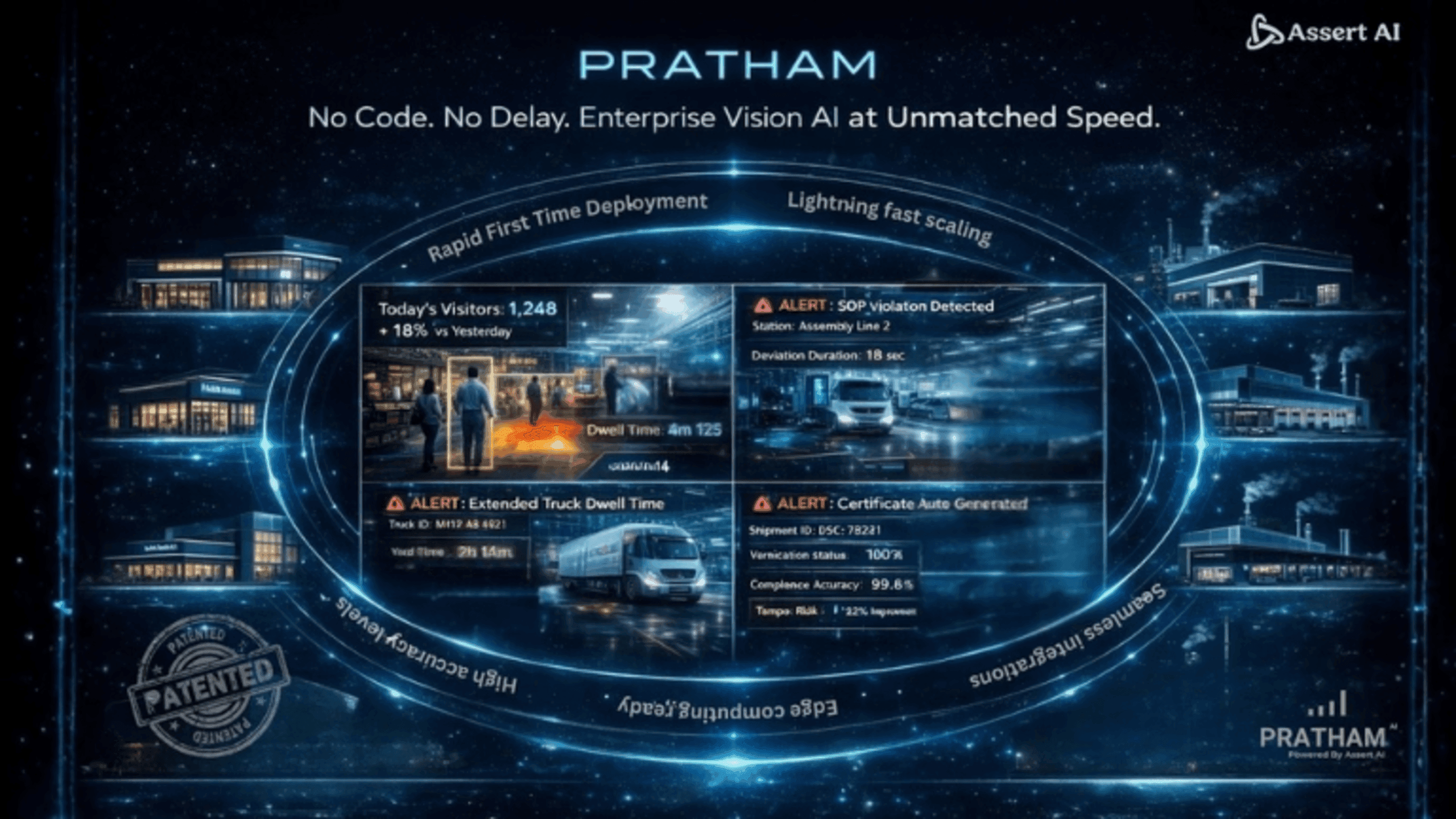

Visual AI systems can connect to your existing CCTV cameras to monitor, track, and alert teams in real-time. Here’s how it makes a tangible difference:

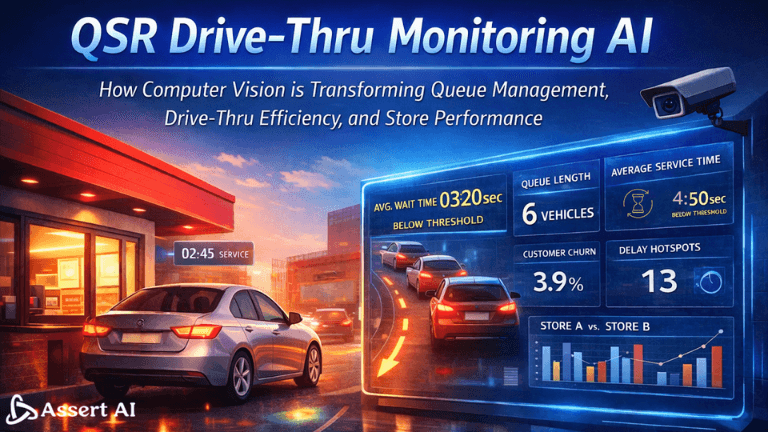

- Real-Time Dock Occupancy Monitoring

Instantly see which docks are occupied, which are free, and how long trucks have been waiting, without walking the yard. - Truck Arrival Detection

No need to rely on manual call-ins. Visual AI detects when a truck arrives at the gate or dock and automatically notifies your team. - Dwell Time Alerts

Set thresholds: If a truck stays beyond the allocated unloading time, the system raises an alert, helping you intervene before detention kicks in. - Data for Continuous Improvement

Visual AI generates real-time dashboards and reports on average dwell times, utilization rates, and peak congestion hours- giving you the data you need to fix systemic issues.

And the best part? These systems typically work with your existing infrastructure. So in most cases, no expensive hardware swaps are required.

Find out how to stop revenue leaks → Reduce Retailer Deductions with Computer Vision

Reducing detention and dock delays is a leadership responsibility. It’s about bringing together processes, people, and, where needed, technology to ensure smooth, profitable operations. Start with planning, communication, and data, and if blind spots remain, Visual AI can fill the gaps through real-time warehouse tracking.

In an industry where every wasted minute chips away at margins, better visibility means better profitability.

If you’d like to see how Visual AI works in action, request a walkthrough. Start fixing detention problems today, not tomorrow.

Sources:

- ATRI Detention Impact Report, 2019: https://truckingresearch.org/2019/12/17/impact-of-detention-on-truckers/

- FreightWaves Research: https://www.freightwaves.com/news/detention-of-truck-drivers-continues-to-increase-atri-study-says