Introduction

In composite manufacturing, even the most seasoned operations teams are often frustrated by how elusive consistent quality can be. Despite best practices, defects still creep in, rework cycles drain productivity, and warranty claims show up long after shipment. The cost of these lapses isn’t operational, it’s strategic.

As composite manufacturing matures to meet the rigorous standards of industries like aerospace, wind energy, automotive, and defense, the financial impact of poor quality has become impossible to ignore. AI in quality assurance is now being seriously evaluated, not as a futuristic add-on but as an essential lever to protect margins and reputation.

The Financial Toll of Poor Quality

The consequences of poor quality extend far beyond the visible scrap bin or late-stage rework:

1. First Pass Yield (FPY) Losses Add Up Quickly

Low FPY in composite manufacturing often stems from material inconsistencies, misaligned layups, or minute deviations during curing. Every failed inspection is a sunk cost in labor, materials, machine time and opportunity cost. In high-mix, low-volume composite manufacturing environments, FPY rates can plummet to below 60% in some facilities, significantly affecting throughput.

2. Costly Rework and Scrap

Unlike conventional materials, composite rework is both expensive and uncertain. The rework of a composite blade, panel, or casing might involve thermal reshaping, sanding, or full replacement- none of which guarantee restored strength. Some estimates suggest rework can consume up to 50% of total production time for certain SKUs.

3. Warranty Claims and Reputation Damage

Subpar quality often isn’t fully visible until the product is already in use, leading to downstream failures and warranty claims. According to ASQ (American Society for Quality), the cost of poor quality can consume up to 20% of total sales in manufacturing companies, depending on the complexity and regulatory requirements of the industry.

[Source: https://asq.org/quality-resources/cost-of-quality]

Warranty-related costs don’t just include direct replacements; they encompass logistics, field support, reputation damage, customer churn, and potential litigation.

4. Safety and Liability Risks

When structural integrity is compromised, especially in industries like aerospace or automotive, the risks are systemic. According to Boeing’s AeroMagazine, around 80% of airplane accidents are caused by human error, while only 20% are due to machinery malfunctions.

Yet, investigations often reveal that what appears to be operator error is frequently rooted in design or manufacturing process limitations.

[Source: Boeing. MEDA Investigation Process. 2008. https://www.boeing.com/commercial/aeromagazine/articles/qtr_2_07/article_03_2.html]

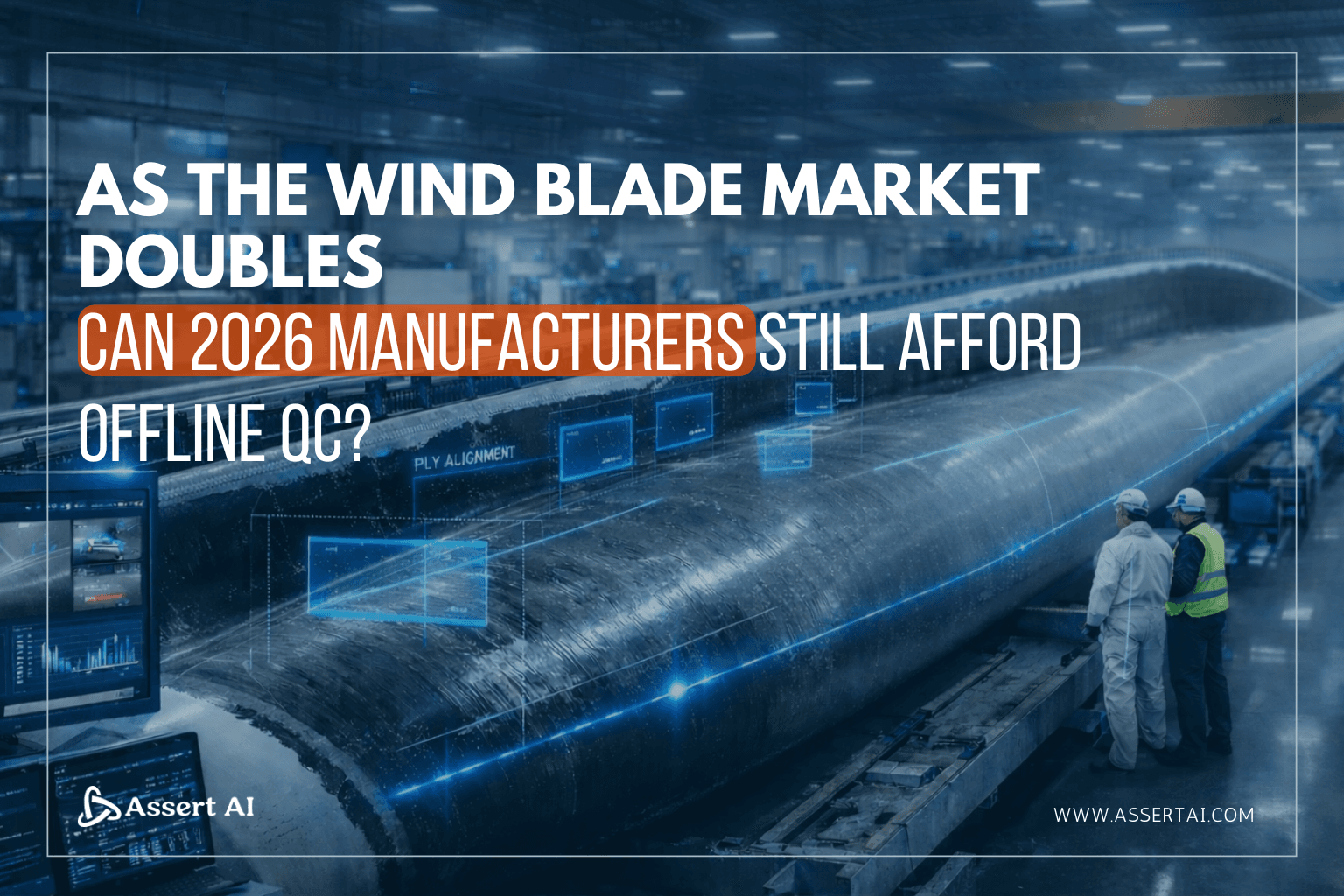

Why Composite Manufacturing Needs Precision at Scale

The nature of composite manufacturing makes traditional quality inspection and assurance methods inherently inefficient:

- Manual inspection is slow and subjective- even with checklists and gauges.

- Destructive testing limits scale– only a sample is tested, and defects can still escape.

- NDT methods (ultrasound, thermography, X-ray) are costly and often require downtime or specialized staff.

The demand for precision at scale, without slowing down production, calls for a smarter approach.

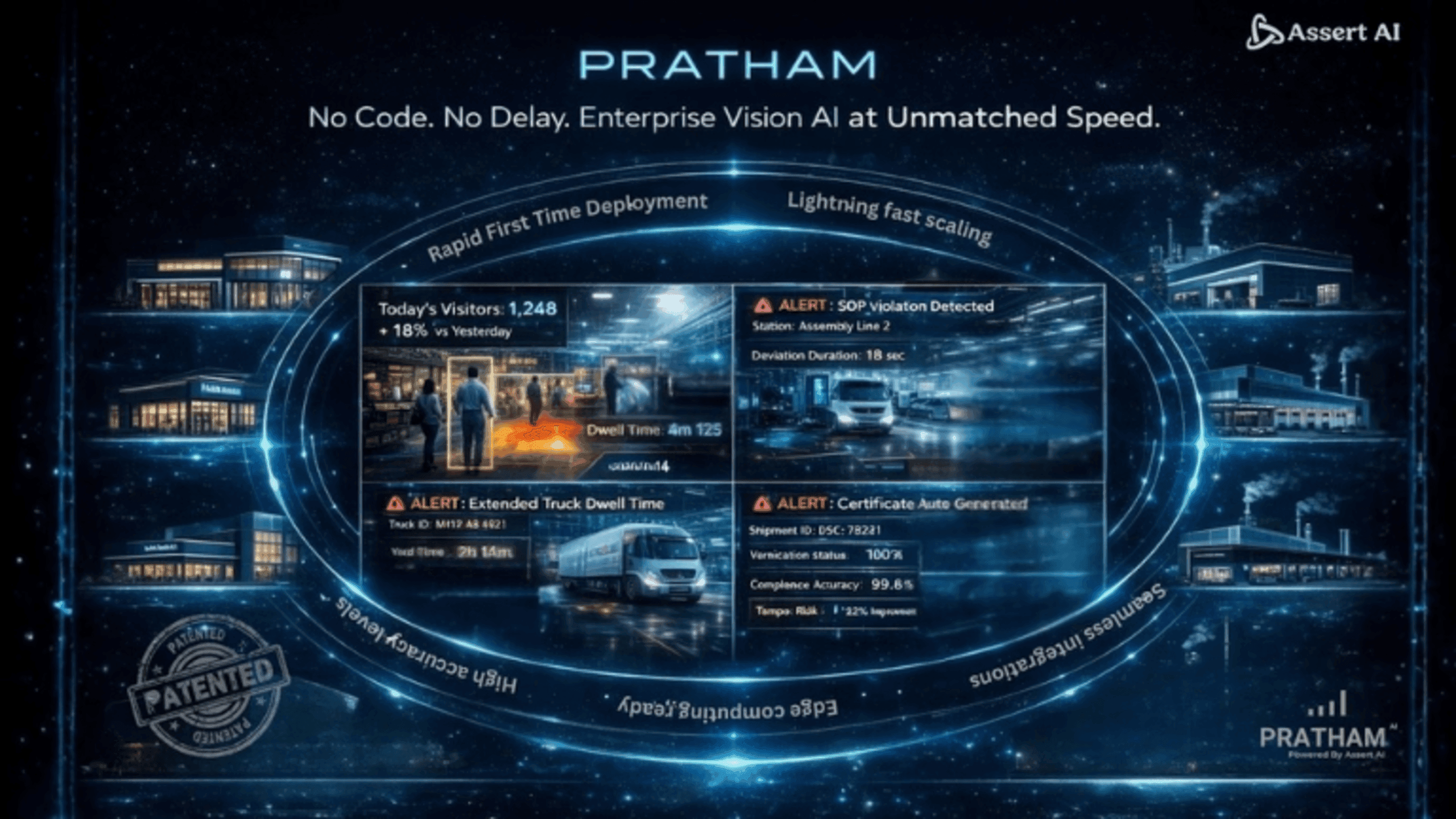

The Role of AI in Quality Assurance

While many quality tools have come and gone, AI in quality assurance represents a real shift- an intelligent layer that integrates into the process and makes it more resilient, not more complicated.

Here’s how AI for quality control is changing the game:

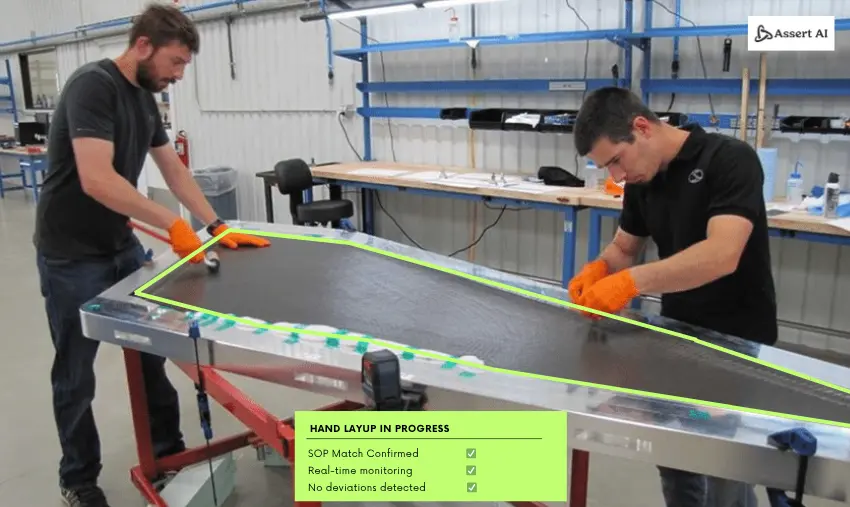

- Real-time visual inspection using computer vision in manufacturing allows systems to detect defects invisible to the human eye.

- AI learns from process history, flagging patterns of deviation and offering predictive quality alerts, not just retrospective defect logs.

- AI-driven computer vision solutions for manufacturing eliminate subjectivity, standardize evaluation, and enable traceability at every stage of production.

Unlike rule-based systems, AI adapts to new defect types, learning as it goes, making it far more scalable than traditional QA workflows.

For example, you can explore how our computer vision company is already delivering tangible benefits in composite and precision manufacturing by enabling real-time quality control across layers and curing stages.

Composite Quality Issues Can’t Be Solved with Conventional Methods Alone

There are certain lean manufacturing goals that simply cannot be achieved through conventional QA:

- Zero Defect Manufacturing: Impossible without consistent, objective, and real-time inspection.

- 100% In-Process Inspection: Unfeasible with human operators or traditional NDT.

- Closed-loop Feedback Systems: AI is required to feed data from the line back to process settings automatically.

Learn how AI Vision is going beyond destructive testing in composite manufacturing.

AI in QA: A Strategic Shift, Not a Tech Upgrade

Reducing the cost of poor quality in composite manufacturing isn’t just about cutting scrap or improving yield, it’s about safeguarding margins, de-risking operations, and building trust with customers.

While Lean, Six Sigma, and Total Quality Management will always be foundational, AI in QA adds a layer of precision and proactivity that human-dependent systems simply cannot match.

Also read: How Assert AI is transforming AI in manufacturing with advanced computer vision.

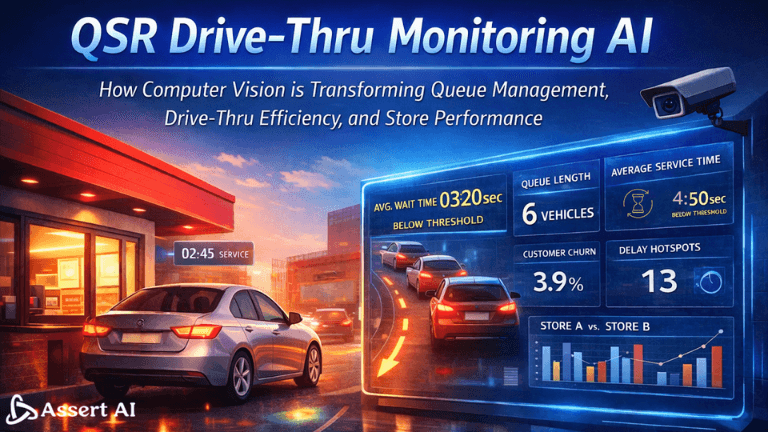

Let’s Talk—Is Computer Vision Right for You?

If you’re seeing gaps in your FPY, struggling with warranty costs, or simply want to understand where quality breaks down, we’d be happy to assess how computer vision in manufacturing can fit into your roadmap.

📍 Invite us to your facility—we’ll walk the floor with your team and offer practical guidance on:

- What quality bottlenecks are addressable with AI

- Whether your current process is ready for computer vision

- What ROI and metrics you can expect

👉 Reach out to schedule a no-obligation consultation and discover the right-fit quality strategy for your composite operations.