The Stakes Are Sky High. Literally.

From 250-foot wind turbine blades slicing through the atmosphere to next-generation aircraft with carbon fiber fuselages, composites form the foundation of mission-critical sectors such as aerospace, renewable energy, marine, and automotive. Their high strength-to-weight ratio offers superior performance but also demands absolute precision. Even a minor flaw can translate into significant safety concerns and multi-million-dollar liabilities.

A Legacy Challenge in a High-Tech World

Despite advanced technologies in adjacent areas, quality control in composite manufacturing remains archaic. Destructive testing, that is, breaking parts to validate their integrity, still dominates many production lines. This approach is not only slow and costly but also risks overlooking defects in the vast majority of parts that go untested.

The consequences of a single undetected error include:

- Safety hazards and failed audits

- Production downtime and rework costs

- Potential recalls and legal liabilities

Composite Manufacturing: A Complex, Irreversible Process

Manufacturing with composites involves hundreds of meticulously sequenced steps- from layering carbon fiber and applying resins to vacuum bagging and curing. In some workflows, there are over 800 stages. Once the resin cures, rework becomes nearly impossible. A minor oversight, such as an air bubble or dry spot can compromise structural integrity and performance.

Notably, a mid-spin wind turbine blade failure was traced back to insufficient resin during production. Read the full story here.

Destructive Testing: A Costly Standard

Destructive testing remains the traditional method for quality control:

- Sacrificing real components for sample tests

- Long turnaround times for lab analysis

- Low coverage- only a fraction of parts are tested

It’s an outdated, inefficient model that belongs to a different era.

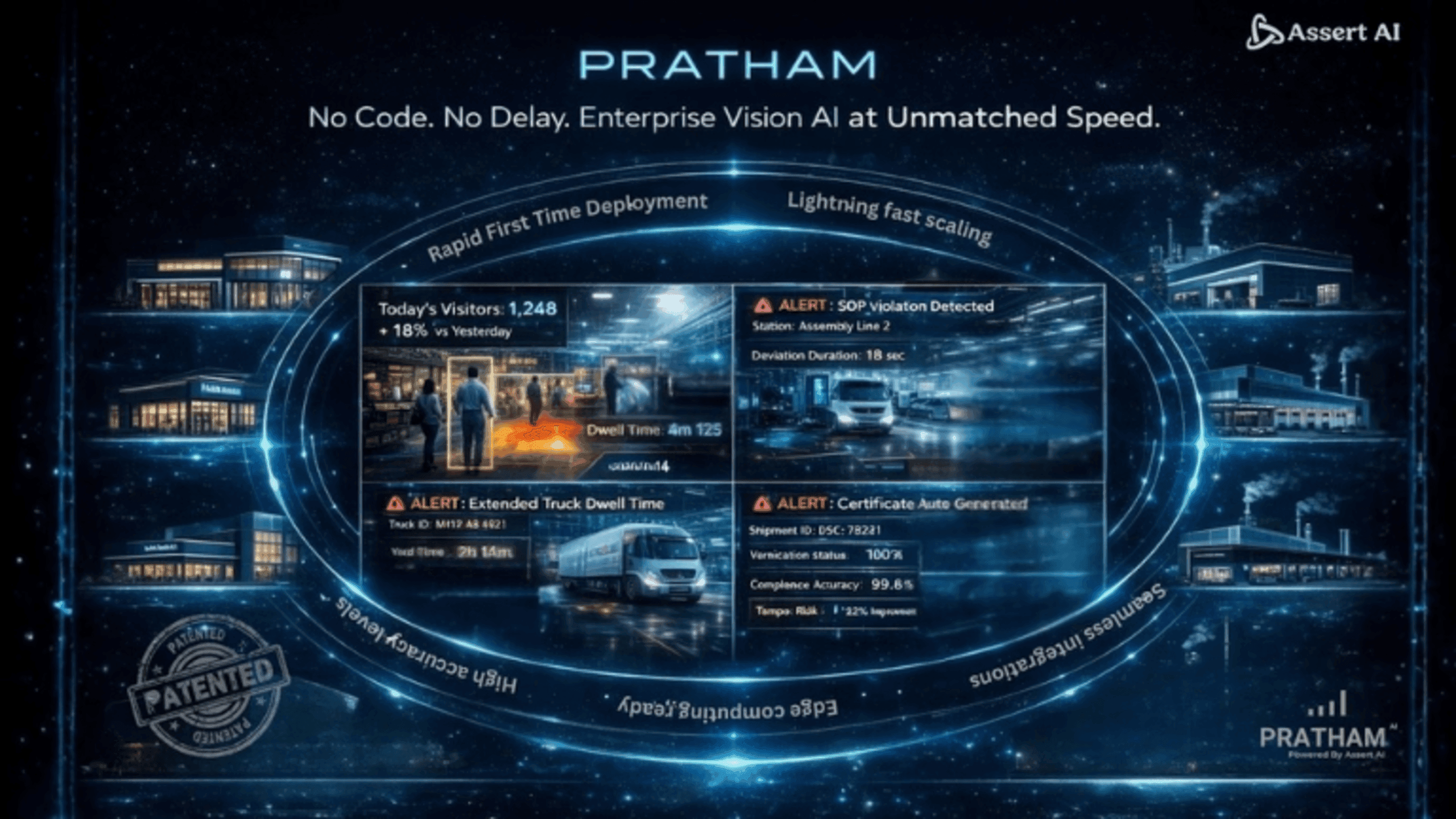

AI Vision: Transforming Quality from Afterthought to Real-Time Assurance

AI Vision introduces a paradigm shift, ensuring quality during the manufacturing process itself. It leverages high-resolution cameras and machine learning models to provide:

- Real-time process monitoring

- Laser-guided SOP (Standard Operating Procedure) projections

- Automated visual verification and compliance logging

- Traceable quality documentation with timestamps and operator IDs

This system enhances consistency, mitigates human error, and embeds quality control into every production step.

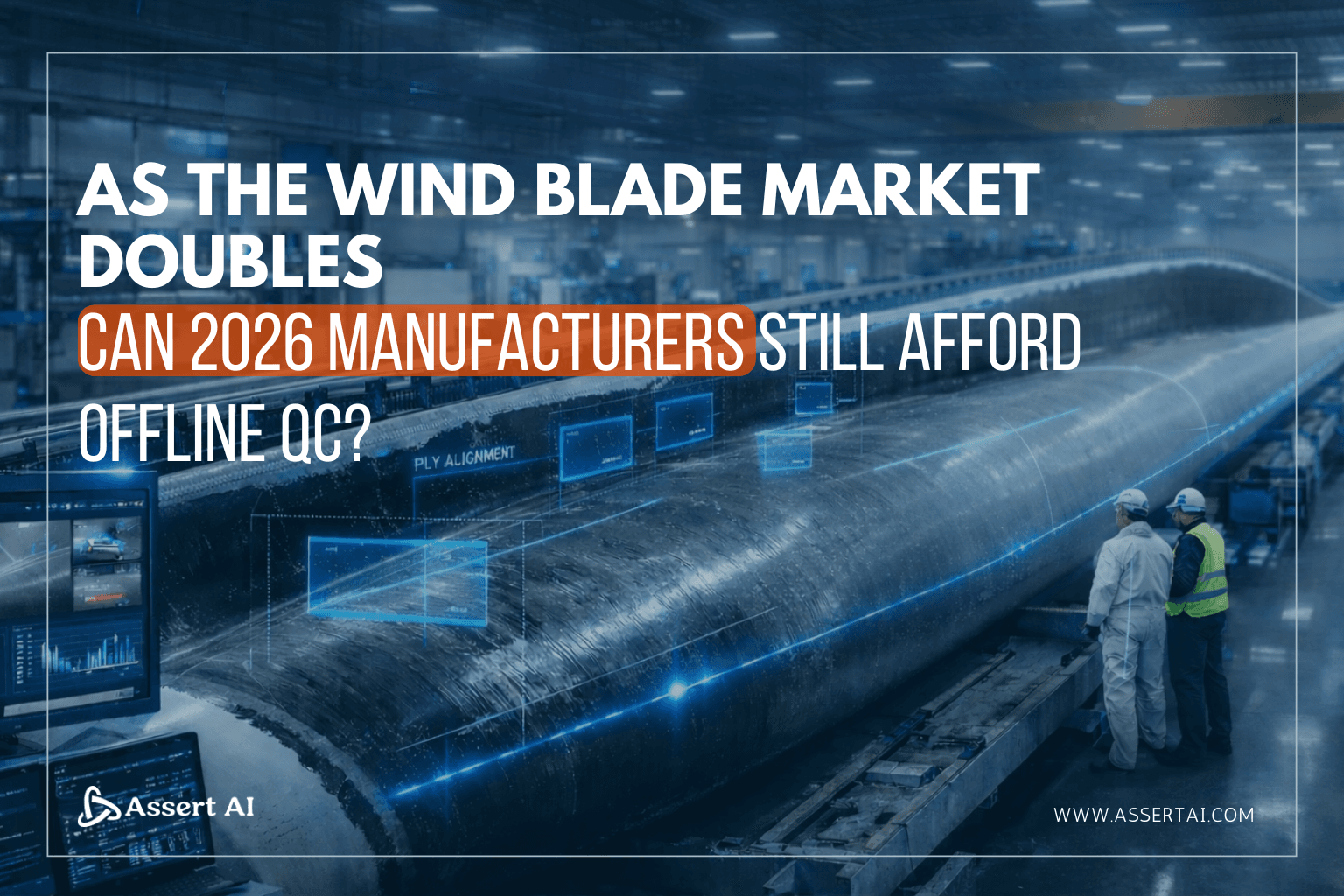

A High-Impact Use Case: Wind Turbine Blades

Wind turbine blades, often exceeding 100-250 meters in length, are constructed manually- layer by layer. Most defects, such as air entrapment, dry spots, and misalignments, are visual and easy to miss but have serious consequences. The controlled, well-lit environments in which blades are produced make them ideal candidates for AI Vision systems.

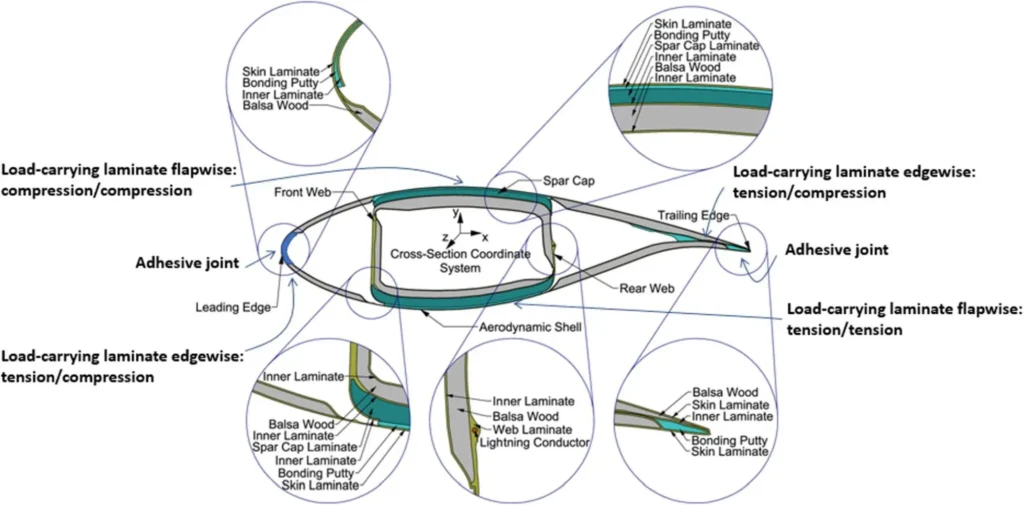

Understanding the Hidden Damage Risks in Blades

Numerous studies have identified key defect types that originate in early manufacturing stages:

| Type | Description |

| Type 1 | Damage formation and growth in the adhesive layer joining skin and main spar flanges (skin/adhesive debonding and/or main spar/adhesive layer debonding ). |

| Type 2 | Damage formation and growth in the adhesive layer joining the up and downwind skins along leading and/or trailing edges (adhesive joint failure between skins ). |

| Type 3 | Damage formation and growth at the interface between face and core in sandwich panels in skins and main spar web (sandwich panel face/core debonding ). |

| Type 4 | Internal damage formation and growth in laminates in skin and/or main spar flanges, under a tensile or compression load (delamination driven by a tensional or a buckling load ). |

| Type 5 | Splitting and fracture of separate fibres in laminates of the skin and main spar (fibre failure in tension; laminate failure in compression ). |

| Type 6 | Buckling of the skin due to damage formation and growth in the bond between skin and main spar under compressive load (skin/adhesive debonding induced by buckling, a specific type 1 case ). |

| Type 7 | Formation and growth of cracks in the gel-coat; debonding of the gel-coat from the skin (gel-coat cracking and gel-coat/skin debonding ). |

Detecting the Undetectable: The Real Risks Inside Every Blade

Source: Science Direct

These defects compromise structural performance and can trigger warranty claims, recalls, and reputational risks.

Assert AI: Preventing the Unseen

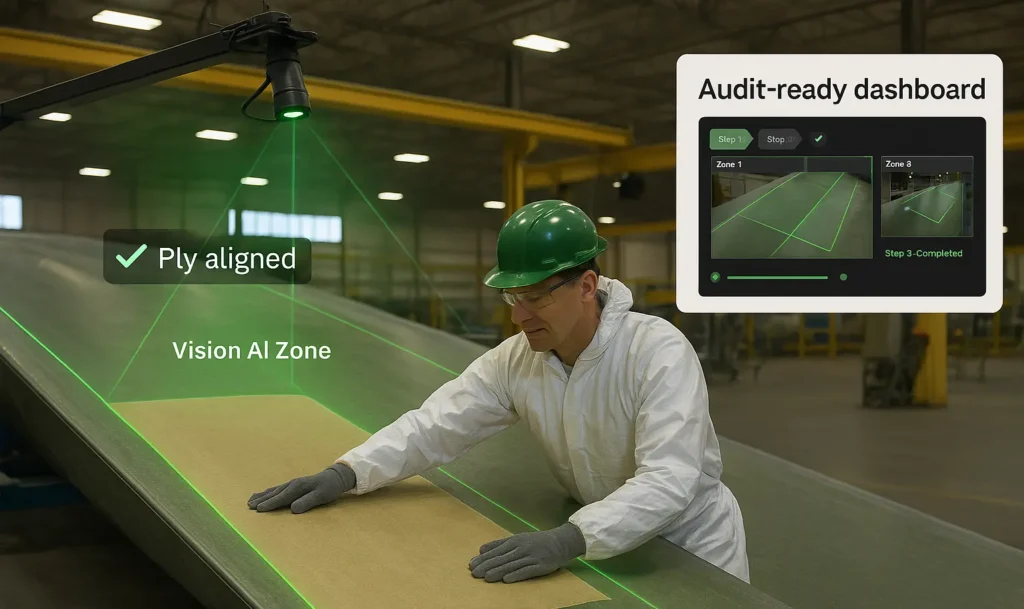

Assert AI’s computer vision solution is engineered for precision and scalability. Key features include:

- Visual SOP enforcement through laser-guided projections

- Real-time monitoring of resin flow, curing conditions, and vacuum sealing

- AI-powered defect detection: air pockets, fiber misalignments, and delaminations

- Digitally searchable QA documentation with traceable image records

These tools enable manufacturers to catch and resolve issues before they escalate, reducing scrap and safeguarding quality.

Built for Mission-Critical Environments

One of our deployments in a blade facility features over 30 cameras and laser projectors across a single production line. The AI ensures step-by-step compliance, backed by timestamped image logs for each operation. Operators are guided clearly, and managers gain reliable visibility into every stage.

Industry Applications Beyond Wind Energy

Assert AI’s AI Vision technology supports industries where precision and accountability are non-negotiable:

- Aerospace: Monitors layup and autoclave prep to prevent grounding defects

- Marine: Identifies voids and alignment issues in hulls and pressure components

- Automotive: Ensures consistent bonding and finishing in carbon fiber panels

- Gas & Pressure Vessels: Tracks filament winding and tensioning for pre-load compliance

The Economics of Errors

According to the Journal of Composite Materials, defect rates in pre-preg composites range between 5% and 15%, depending on manufacturing discipline and environmental controls.

- Blade rework costs: Up to $30,000 (Wind Energy – Wiley)

- New blade costs: ~$200,000

- FAA and NTSB have linked composite defects to aircraft recalls (NTSB, FAA, Business Insider)

As composite usage grows, so does the risk of waste. By 2050, the wind and aviation industries alone may generate over 840,000 tonnes of carbon fiber-reinforced plastic waste (JETCAM).

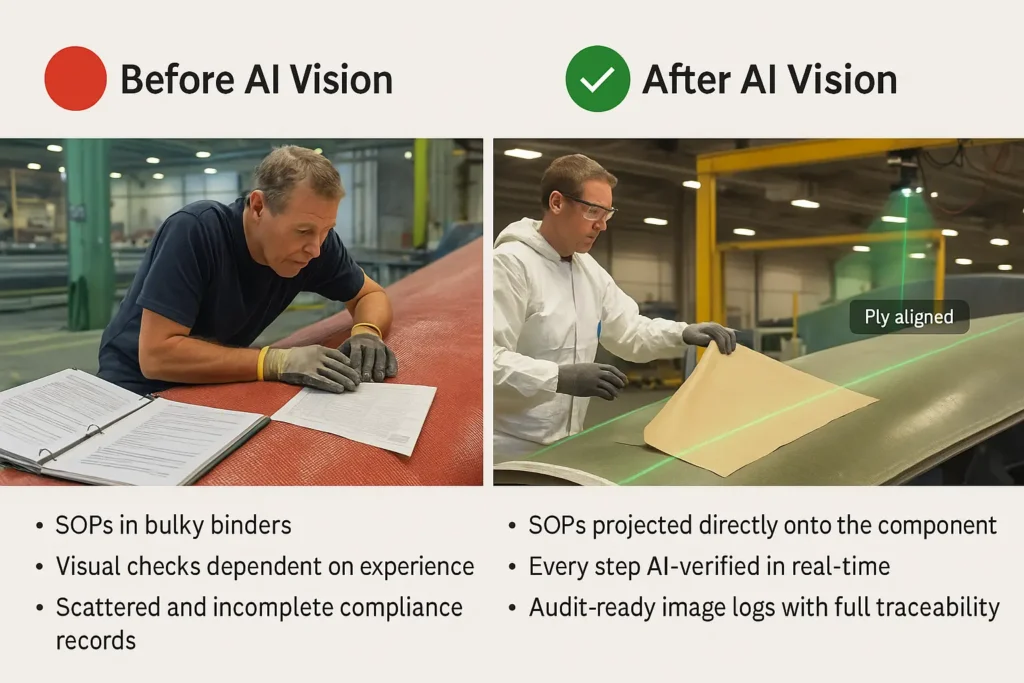

From Paper SOPs to Smart Projections

From Reactive to Preventive

In composite manufacturing, the cost of imperfection is too high to ignore. AI Vision makes quality assurance proactive, not reactive, detecting anomalies during production rather than after delivery. For industries operating at the edge of innovation and safety, Assert AI offers the clarity, control, and confidence needed to scale without compromise.

Explore how Assert AI can help you drive quality at every step

Contact Us or Visit our LinkedIn Page to learn more.