Wind turbine blades are engineering marvels of massive structures stretching up to 120 meters long and built to withstand decades of extreme wind, rain, hail, and thermal stress. They are among the most sophisticated composite structures ever manufactured. But when they fail, the impact is not just about a broken piece of equipment, it’s about millions lost, months wasted, and reputations damaged.

In a recent incident highlighting the critical importance of blade integrity, a Siemens Gamesa 5.X turbine at a wind farm in Finland suffered a “blade liberation” (i.e., a blade broke off), prompting an ongoing investigation into the cause.

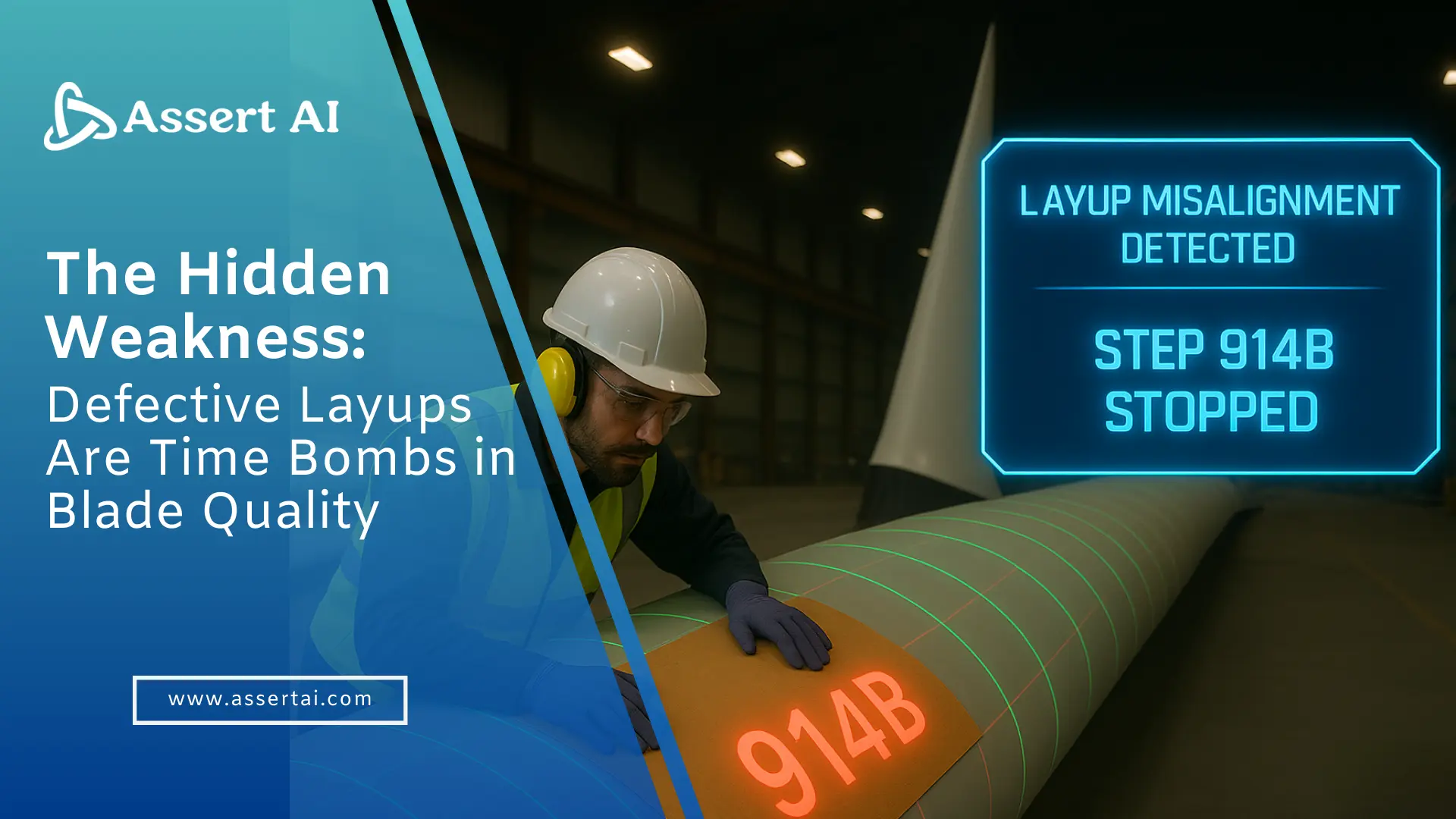

The irony? Most blade failures don’t start with a visible crack tearing through fiberglass. They start with something much smaller: a tiny void, a micro-crack, or a fiber misalignment, often invisible to the human eye during production. Left undetected, these small defects snowball into catastrophic breakdowns that cost far more than manufacturers realize.

The Expensive Problem You Can’t Ignore

Direct Blade Costs

Replacing a single onshore blade averages $200,000 (Wind Watch Report). Offshore replacements are dramatically higher, sometimes $500,000+, when you include transport, cranes, offshore vessels, and installation logistics.

Blade Failures

The study reports an average of 3,800 blade failures per year globally, with offshore turbines experiencing on average 8.3 blade failures per turbine annually (Wind Watch Report).

Escalating Repair Costs

Defects follow a brutal cost curve:

Category 2 defects cost a few thousand dollars to fix early in production.

Category 4 defects are 6× more expensive to repair.

Category 5 defects? 12× costlier, because they often require structural rework, specialized materials, retesting, and production delays.

And here’s the kicker: if a defect escapes into full-scale testing, manufacturers can lose $300,000–$750,000 in wasted blade production, retesting, and lost delivery schedules before the blade ever reaches a wind farm.

The Industry-Wide Scale

Globally, there are an estimated 3,800 blade failures annually (Windpower Monthly). These failures aren’t outliers, they’re systemic, and the global push for renewable energy means the risk is only growing.

Also Read: Cost of Poor Quality in Composite Manufacturing and How AI in Quality Assurance Can Help

Why Failures Keep Happening

Despite high-tech processes, several factors allow failures to slip through:

Human Error: Manual inspections struggle to detect voids, micro-cracks, or subtle adhesive failures. Even experienced inspectors miss defects that later trigger major failures.

Hidden Defects: Many flaws like fiber waviness, resin voids, or delamination occur inside the blade and are invisible until destructive testing or failure in the field.

Late Detection: Traditional quality checks often happen too late in the production cycle, when defects are already baked in. Fixing defects is costly, as it delays entire supply chains.

And in an industry where one blade failure can idle a 4–12 MW turbine, the ripple effect is enormous financially, and also on clean energy targets, grid reliability, and investor confidence.

ORBIT: Turning Blade Failures into Preventable Events

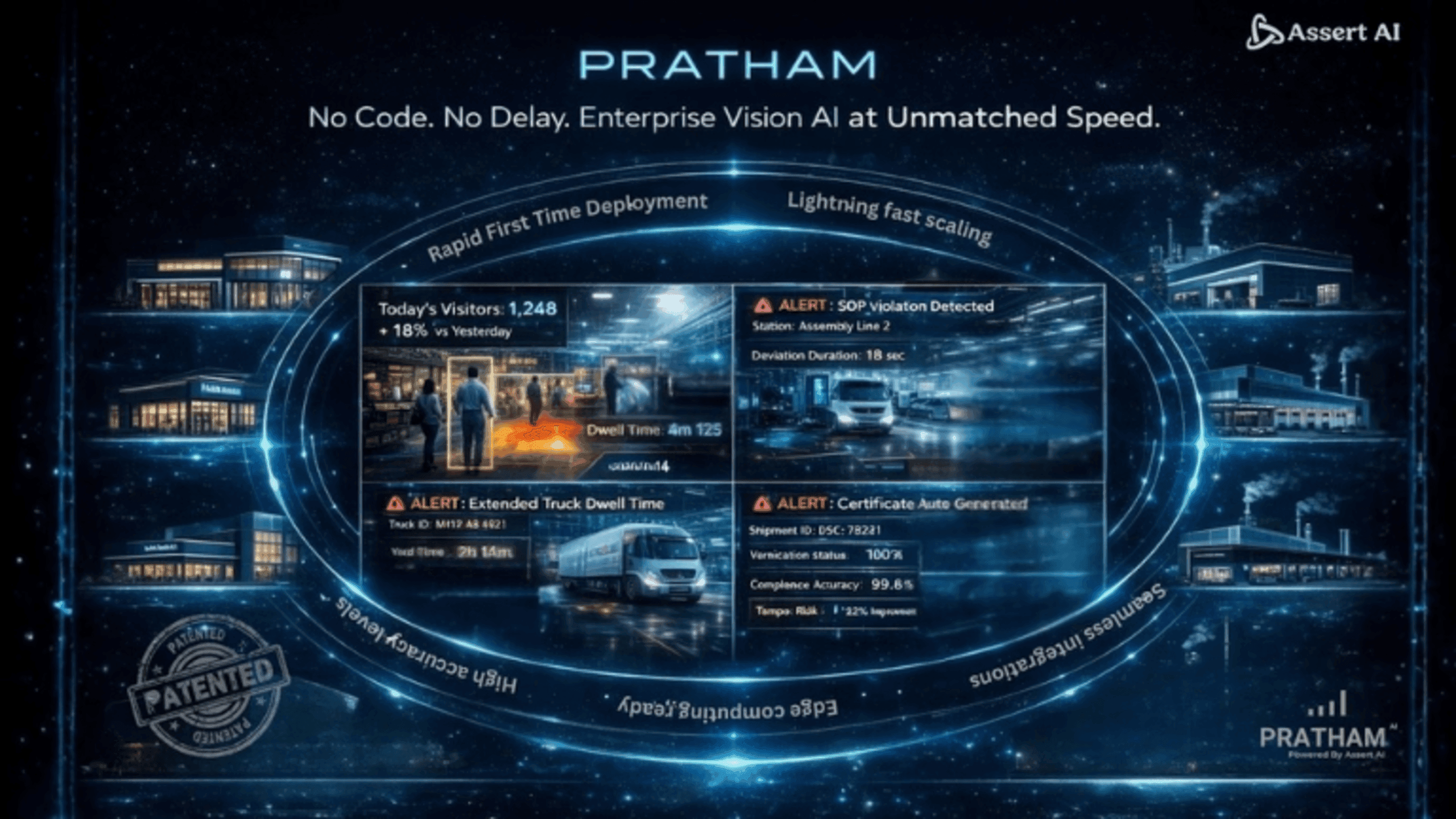

So how do you stop the problem before it spirals? That’s where ORBIT comes in bringing computer vision and AI to blade manufacturing with artificial intelligence in quality control in ways traditional inspections can’t.

Early Detection Where It Matters

ORBIT detects micro-cracks, voids, fiber misalignments, and delamination as they happen long before they evolve into catastrophic defects. What’s invisible to human eyes, ORBIT’s vision models can spot in real time.

Continuous, Not Periodic, Checks

Instead of random spot checks, ORBIT provides continuous monitoring throughout the production cycle. Every square centimeter of the blade is scanned, ensuring no anomaly slips past.

Data-Driven Insights

Each defect is automatically logged, classified, and stored in a database, building a knowledge system of failure patterns. Over time, this enables predictive modeling so manufacturers can catch today’s defects, and prevent tomorrow’s.

Fewer Reworks, Lower Scrap

Catching issues early means avoiding expensive rework or total blade scrapping. For OEMs, that translates to millions saved annually in reduced scrap rates and lower warranty reserves.

Protecting Reputation

A single in-field failure can ripple into warranty claims, legal disputes, damaged customer relationships, and brand erosion. ORBIT’s early intervention ensures blades meet quality standards and helps to build trust with wind farm developers and investors.

Also Read: Quality Checks in Manufacturing: Why Computer Vision Is Becoming Essential

Beyond Cost: The Bigger Picture

The wind industry is projected to grow 60% globally by 2030 (IEA). With such aggressive growth, every delay, scrap, or warranty claim is a financial hit, and a setback in the global race to expand renewable energy.

OEMs and manufacturers face mounting pressure to scale faster, cut costs, and deliver blades with zero tolerance for hidden defects. Traditional inspections cannot keep up with that pace. ORBIT equips manufacturers with the tools to deliver precision, consistency, and reliability at scale.

The Real Environmental Cost: Wind Blade Waste Is Undercutting “Clean Energy”

The Hidden Weakness: Defective Layups Are Time Bombs in Blade Quality

Sealing the Cracks Before They Break You

Blade failures cost money, trust, time, and progress toward renewable energy goals.

With ORBIT, manufacturers can leverage artificial intelligence in quality control by moving from reactive firefighting to proactive prevention. Every blade that leaves the factory floor is backed by AI-driven assurance, protecting margins, timelines, and reputations.

Don’t let invisible defects derail your growth. ORBIT ensures every blade is a shield against hidden losses.