Wind energy is celebrated as the clean future. Gigantic turbines dot coastlines and farmlands, silently generating carbon-free power. But behind the impressive silhouettes is a growing problem: wind turbine blade waste.

While nearly 94% of a wind turbine is recyclable from steel towers to copper wiring the blades remain the stubborn exception. Built from advanced composite materials for strength and lightness, they’re also nearly impossible to recycle at scale. This gap in wind turbine blade recycling is threatening to undermine the entire industry’s sustainability promise.

Read: The looming 840,000 ton waste problem that isn’t single-use plastics

The Scale of the Wind Turbine Blade Waste Problem is Accelerating Faster than Most Projections Anticipated

Massive Landfill Loads

According to Chemical & Engineering News, by 2050, up to 43 million metric tons of blade waste could pile up in landfills if recycling technologies don’t mature quickly. To put that in perspective, that’s the equivalent weight of 430,000 fully loaded Boeing 747 aircrafts lying useless in landfills instead of fueling the green transition.

Annual Waste Growth

The problem isn’t distant, it’s accelerating. Global blade waste is already 100,000 tonnes per year, and studies predict it could double to 200,000 tonnes annually by 2030 (ScienceDirect, 2025). Every year, thousands of decommissioned or rejected blades add to the waste mountain.

The Wind Turbine Blade Waste Problem

Blades are primarily built from fiberglass-reinforced composites with resin bonding. These materials are designed for durability, flexibility, and resistance to fatigue but those very qualities make them hard to break down or recycle using current infrastructure. Unlike steel or aluminum, there’s no simple “scrap and melt” pathway. This growing pile of composite blade waste has no scalable recycling pathway today.

Environmental Risks

Disposing of composite materials is particularly challenging because of the long-lasting durability of the resins and fibers that make them. These materials can take hundreds, even thousands, of years to degrade. If not managed properly, composite waste may release harmful substances into the soil and groundwater, creating serious environmental hazards and endangering the health of nearby communities.

GE Vernova has indicated that a “manufacturing deviation” likely caused the Vineyard Wind blade failure. According to the GE Vernova spokesperson, the preliminary investigation suggests the issue stemmed from insufficient bonding– a flaw that should have been detected by modern wind blade quality control systems.

Why Wind Blade Manufacturing Generates So Much Scrap

Manufacturing Defects in Wind Blade Manufacturing

A significant share of blades never even reach the wind farm. Subtle flaws such as voids, delamination, or resin-rich areas can render blades structurally unsound. Once identified late in production, these blades are scrapped wholesale. Many wind blade manufacturing defects originate during layup and resin infusion but surface far too late.

Destructive Testing

Blades undergo full-scale destructive testing to validate safety. While necessary, this process generates massive waste pieces blades that can’t be repurposed or repaired.

End-of-Life Gaps

Wind farms typically retire blades after 20–25 years. While pilot recycling solutions exist such as cutting blades for cement co-processing the processes remain expensive, energy-intensive, and limited in scale. Most retired blades still end up in landfills.

Without stronger prevention strategies, the wind industry risks creating a legacy of landfill mountains, undercutting the very sustainability mission it champions.

Why Does Blade Waste Matter?

This is about landfill space—but also about sustainability in wind energy and long-term credibility.

Read: Wind Blades that Cannot be recycled are piling up the landfill

ESG Pressures: Investors and regulators now demand proof of circular economy practices. Blade waste threatens compliance with these goals.

Public Perception: Headlines about “wind turbine blades filling landfills” erode public trust in renewable energy.

Hidden Carbon Footprint: Manufacturing and scrapping a blade wastes enormous embodied energy negating much of the carbon savings turbines generate.

The industry cannot afford this contradiction promising clean energy while leaving dirty waste behind.

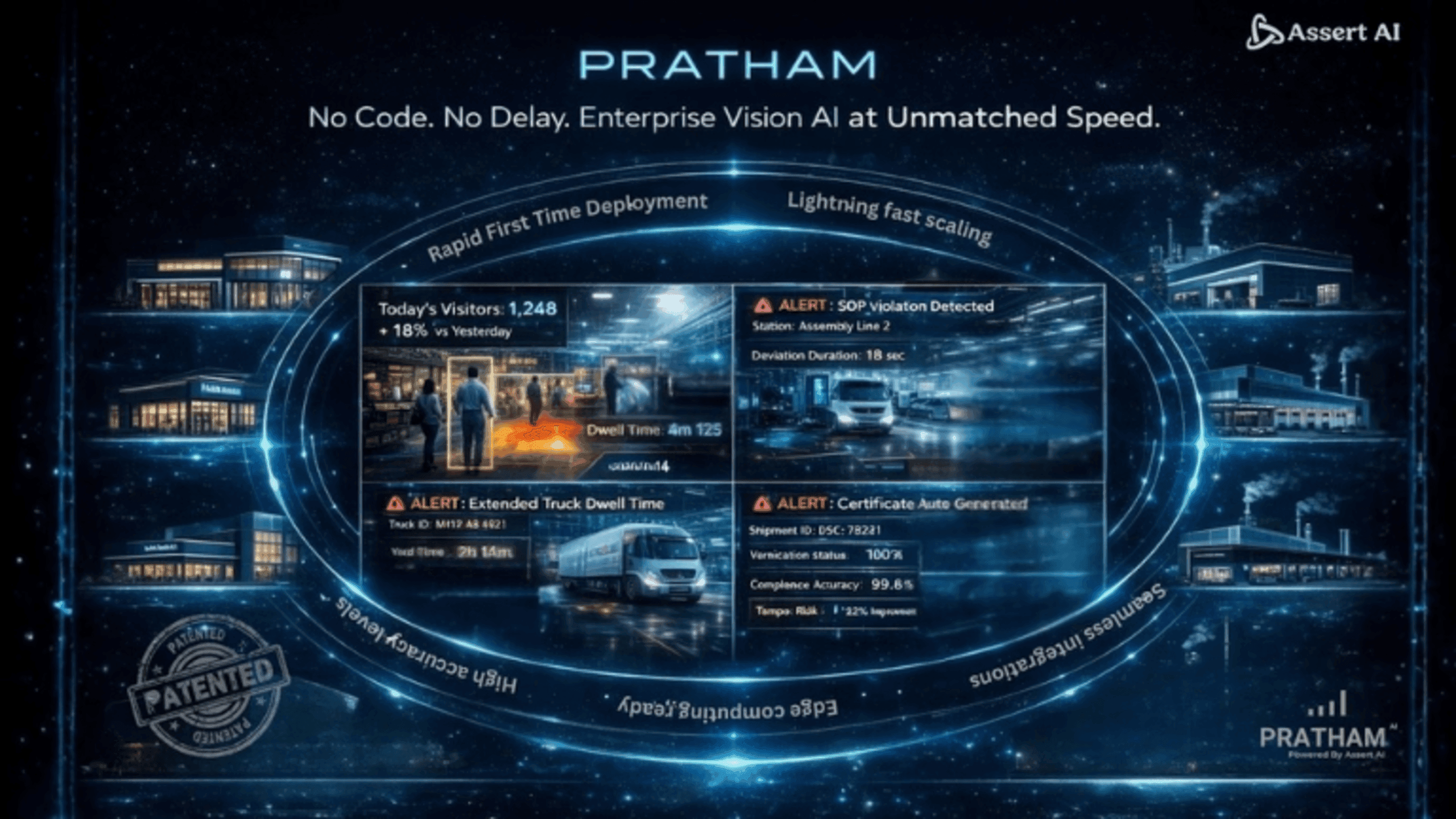

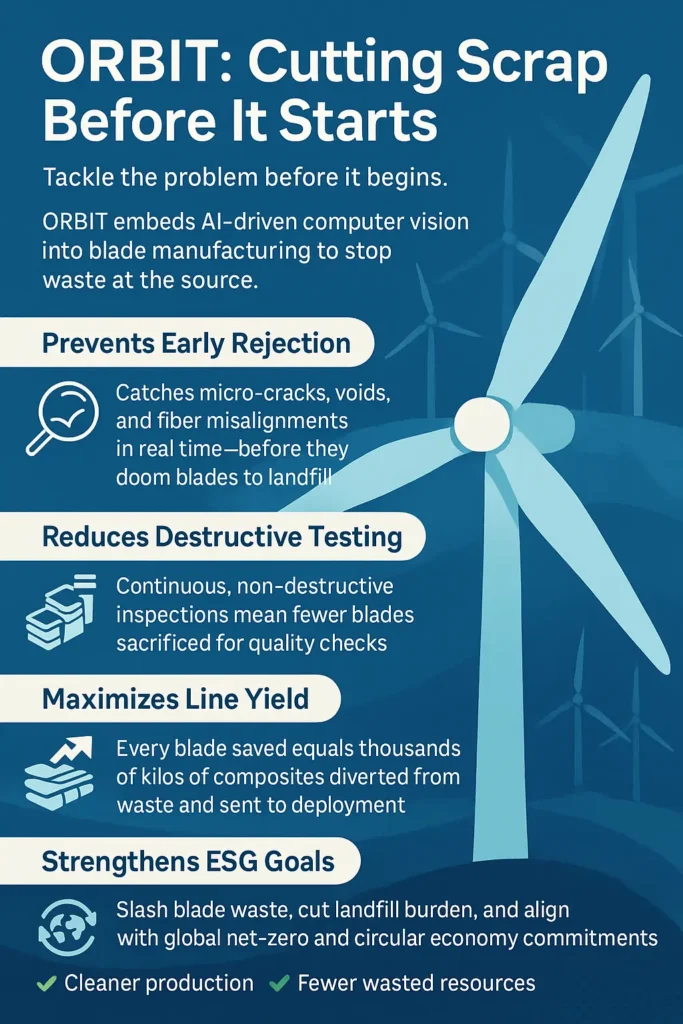

ORBIT: Cutting Scrap Before It Starts

So how can manufacturers tackle the problem before it even begins? That’s where ORBIT (Optimized Real-time Blade Inspection and Tracking by Assert AI) changes the game. By embedding computer vision in wind blade manufacturing, ORBIT reduces waste at the source.

- Prevents Early Rejection

Most scrapped blades are rejected because hidden defects surface too late in production. Optimized real-time inspection catches micro-cracks, voids, or fiber misalignments in real time during manufacturing, before they doom the blade to landfill. ORBIT shifts blade production towards in-process quality control instead of post-failure inspection.

- Reduces Destructive Testing Dependency

Today, destructive testing is often the only reliable way to ensure structural integrity. AI based blade manufacturing monitoring provides continuous, non-destructive inspections, reducing the number of blades that must be sacrificed in testing.

- Maximizes Yield from Each Production Line

Every blade saved equals thousands of kilograms of composite material diverted from landfill. With Real-time inspection and tracking, manufacturers can push more blades through to deployment, increasing yield without increasing scrap rates. Continuous real-time blade inspection improves yield without increasing scrap.

- Strengthens ESG and Sustainability Goals

Global wind leaders are under immense pressure to demonstrate progress toward net-zero and circular economy commitments. By slashing blade waste, ORBIT enables manufacturers to align operations with their ESG promises and improve their sustainability credibility.

The result? Cleaner production, fewer wasted resources, and stronger reputations.

From Blade Waste to a Sustainable Wind Energy Future

The wind industry is on track for explosive growth. That means more turbines, more blades and if unchecked, more waste.

The industry stands at a crossroads. Continue on the current path, and blade waste becomes the Achilles’ heel of clean energy. But adopt solutions like ORBIT, and manufacturers can transform blade production into a closed-loop system that matches the industry’s green promise with green practice.

When a Wind Blade Fails: The Hidden Six-Figure Toll You Never Saw Coming

The Hidden Weakness: Defective Layups Are Time Bombs in Blade Quality

The Cost of Inaction

Every blade saved reduces wind turbine blade waste and strengthens the industry’s sustainability credibility.

With Optimized Real-Time Blade Inspection & Tracking(ORBIT), manufacturers can reduce defects & they even protect profits, preserve resources, and safeguard the industry’s reputation.

Every blade saved from landfill is a step toward authentic clean energy. ORBIT helps bridge the gap between “green promise” and “green practice.”