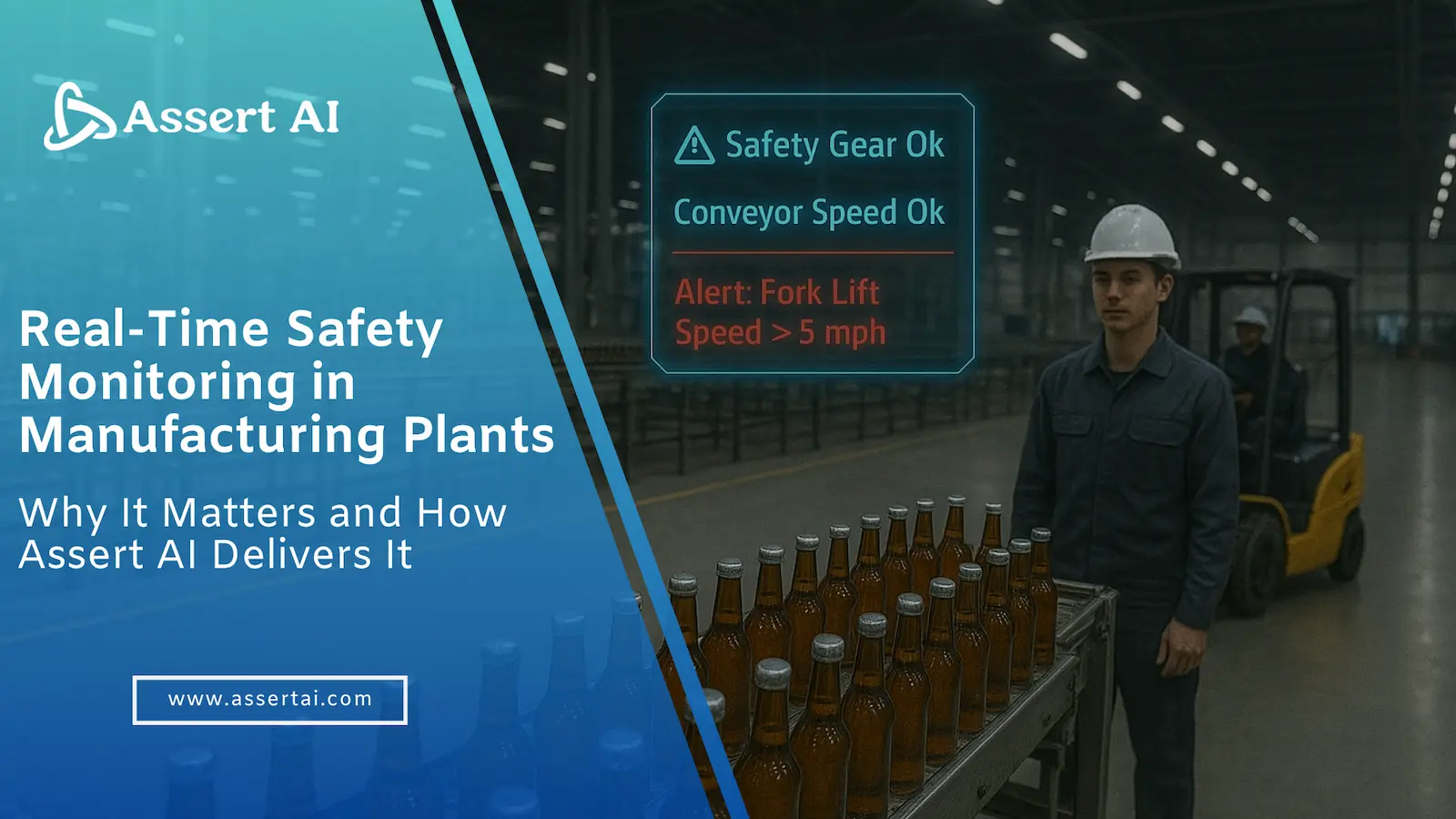

Why Safety Can’t Wait in Manufacturing

Manufacturing plants operate in high-risk, high-output environments where safety lapses can trigger severe accidents, costly downtime, and reputational damage. Despite CCTV deployments across facilities, traditional systems are reactive, they only help after an incident has already occurred.

This is where real-time safety monitoring with AI comes in. By combining existing CCTV infrastructure with computer vision, manufacturers can automatically detect unsafe acts, near misses, and compliance breaches as they happen, not after. Assert AI’s safety solution transforms workplace surveillance into an active shield for employees, machinery, and operations.

Why Real-Time Safety Monitoring is a Game Changer

1. Proactive Accident Prevention

Instead of relying on manual checks or delayed reviews, computer vision identifies risks like missing PPE, unsafe proximity to forklifts, or pathway obstructions instantly. Alerts reach supervisors in real time, enabling immediate corrective action.

2. Improved Compliance and Audit Readiness

Factories face stringent regulatory standards. AI-powered monitoring ensures that PPE rules, emergency exits, fire hose access, and zebra crossing compliance are continuously observed. Compliance data is logged and made audit-ready without manual intervention.

3. Cost Reduction Through Early Detection

Accidents are expensive- not only in human terms but also due to downtime, insurance costs, and supply chain disruptions. Automated safety monitoring reduces the likelihood of these events, preserving both workforce health and business continuity.

4. Scalable Across Facilities

Assert AI’s solution adapts to 500+ cameras across multiple plant facilities, monitoring dozens of use cases simultaneously- from fire detection to intrusion alerts, without increasing manpower costs.

How Assert AI’s Safety Solution Works

At its core, Assert AI transforms passive CCTV networks into an active real-time safety monitoring system that constantly watches for risks, unsafe behavior, and operational anomalies. Here’s how it works in practice:

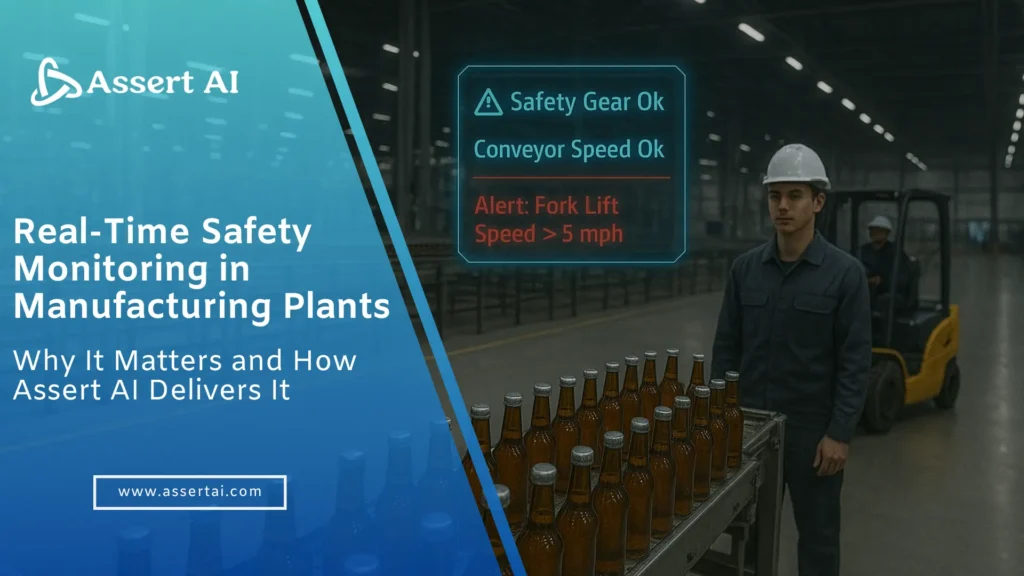

1. Vehicle Safety Monitoring with AI

Manufacturing plants have a high density of trucks, forklifts, and even two-wheelers. Without automation, even vigilant security staff can miss violations. Assert AI introduces:

Automatic Number Plate Recognition (ANPR)

Every vehicle entering or exiting is automatically logged. For instance, if an unauthorized vehicle tries to access restricted areas, the system instantly flags it.

Helmet Compliance for Bikers

If workers or visitors leave the premises without helmets, the system sends an alert to security to prevent injuries on public roads.

Speed Limit Enforcement

If a truck exceeds 20 km/h (or custom threshold) inside plant premises, the system triggers real-time alerts, helping avoid collisions.

Forklift Proximity Alerts

People or two forklifts coming too close (within 5–10 ft) are flagged. In one deployment, this feature prevented multiple near-miss accidents in loading bays.

Ambulance Tracking

Entry and exit of ambulances are timestamped automatically, creating a clear response-time record for safety audits.

2. Worker Safety and PPE Compliance

PPE Detection

Cameras check continuously for helmets, gloves, goggles, and safety vests. For example, if a worker begins unloading chemicals without gloves, supervisors are alerted within seconds.

Pathway Compliance

AI ensures employees walk only on zebra crossings or designated footpaths. Unsafe shortcuts through heavy machinery zones trigger anomaly alerts.

Lone Working Risk Detection

If an operator is spotted alone near boilers or ETP areas, an alert is triggered. Lone working risks are especially critical for emergency response planning.

Conveyor Safety

A serious hazard like workers passing under conveyors are immediately detected and flagged.

3. Facility and Emergency Preparedness

Fire and Smoke Detection

Cameras trained on flames or smoke detect anomalies faster than the human eye. For example, smoke over 30 cm tall visible for more than 5 seconds automatically generates a high-priority alert.

Blocked Fire Hose and Exits

If pallets or machinery block a fire hose or exit for over threshold time (example >3 minutes), the system records it and alerts facility managers.

Emergency Door Use

Any door opened for over 5 seconds outside of drills is logged to ensure no unauthorized escapes or misuse.

Pump Stoppage Alerts

By monitoring red/green indicator lights, AI flags pump downtime instantly, helping maintenance crews respond before operations stall.

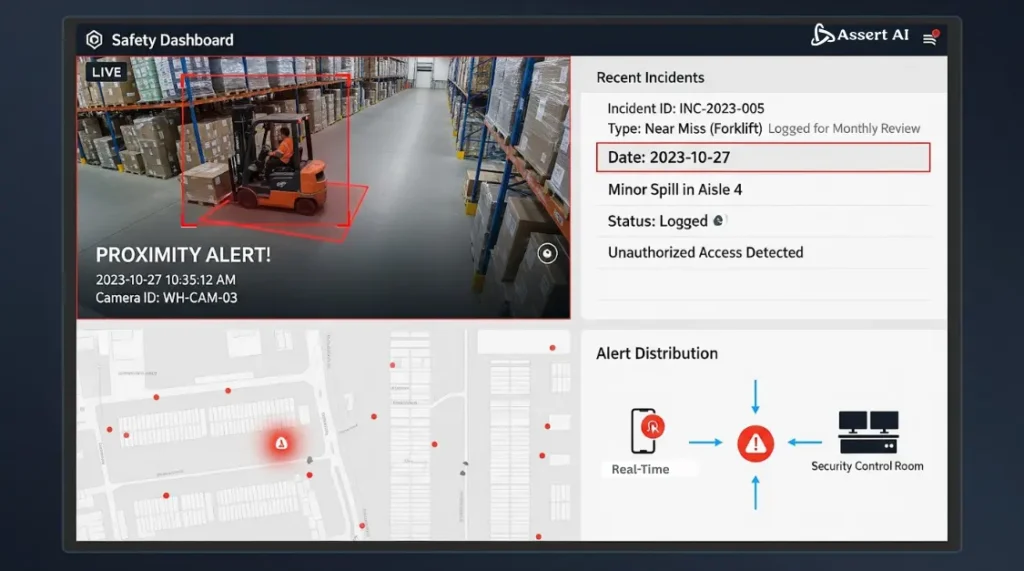

4. Monitoring and Reporting Made Simple

All alerts are centralized into a real-time safety dashboard accessible to supervisors. For example:

- A forklift proximity alert appears on the dashboard with timestamp and camera ID.

- The same incident is logged automatically for monthly safety reviews.

- Alerts can also be pushed to managers’ phones or security control rooms, ensuring fast response no matter where they are.

This holistic approach ensures manufacturing plants are always a step ahead of accidents, making AI-driven safety monitoring not just preventative but also operationally efficient.

Why Assert AI: The Differentiator

- Hardware agnostic: Works with any existing CCTV setup.

- Edge computing for low latency: Ensures no video leaves site, protecting data security while delivering near-instant alerts.

- Customizable use cases: Configurable per facility based on specific risks and compliance standards.

- Proven scalability: From single-plant setups to global rollouts.

Safety as a Strategic Advantage

Every safety lapse in a manufacturing plant comes with a price tag, and it’s rarely small. A forklift accident can halt production for hours, a blocked fire exit can turn into a catastrophic liability, and non-compliance with PPE rules can invite regulatory penalties. Beyond the immediate financial hit, such incidents damage trust with employees, erode brand reputation, and disrupt supply chains.

Relying on traditional CCTV or manual checks means risks are often spotted too late- after injuries, losses, or downtime have already occurred. Real-time safety monitoring powered by Assert AI changes that equation. By detecting hazards the moment they emerge, our solution prevents near misses from becoming accidents and small violations from escalating into million-dollar losses.

Safety is not just compliance anymore; protecting your people, your productivity, and your profitability with Assert AI will help you gain a proactive shield against preventable losses, ensuring that operations remain safe, efficient, and resilient.

FAQs on Real-Time Safety Monitoring in Manufacturing

Q1. What is real-time safety monitoring in manufacturing?

It is the continuous AI-based analysis of workplace video feeds to detect safety hazards like missing PPE, unsafe forklift operation, or blocked emergency exits instantly- allowing supervisors to act before an accident occurs.

Q2. How does AI safety monitoring differ from traditional safety audits?

Safety audits are periodic and manual, often catching risks only after the fact. AI safety monitoring is continuous, automated, and proactive, reducing downtime and preventing accidents in real time.

Q3. Can Assert AI’s system integrate with existing CCTV infrastructure?

Yes. The solution is hardware-agnostic, meaning manufacturers don’t need new cameras. Existing CCTV feeds are leveraged, reducing cost and deployment time.

Q4. What are the most common use cases of computer vision for safety in factories?

Top use cases include helmet and PPE detection, forklift proximity alerts, vehicle speed monitoring, intrusion detection, fire and smoke alerts, lone working risk detection, and blocked emergency exits.

Q5. Is the data from real-time safety monitoring secure?

Yes. Assert AI uses edge computing, meaning all video is processed locally inside the plant. This ensures data privacy while still delivering instant alerts.

Q6. Can real-time safety monitoring help in compliance reporting?

Absolutely. Every alert is logged with video evidence and timestamps, creating a transparent digital record for audits, insurance claims, and regulatory compliance.

Q7. How scalable is the solution across global operations?

The system has been designed to manage 500+ cameras across multiple plants simultaneously. For large enterprises with facilities in different countries, dashboards can consolidate safety insights globally.