Why the “quiet crisis” in logistics deserves attention

In a typical large facility, you are dealing with towers of crates, trucks lumbering in, paperwork flapping in the wind, site staff running between ramps and ramps again. In enterprises with high throughput, be it chemicals, heavy manufacturing, logistics hubs, this kind of visual is more the norm than exception.

As supply chains stretch across geographies and customer expectations tighten, AI in logistics has become imperative for maintaining real-time control, cost efficiency, and operational predictability.

Let’s pull out some hard numbers to ground this:

- According to a recent report on AI in logistics, the sector includes 25+ distinct use cases from routing optimization to dock scheduling, yet many systems remain stuck in pilot mode.

- For dock and yard operations, using computer vision can unlock “real-time visibility into trailer arrivals and departures” which directly affects throughput, utilisation and cost.

- A white-paper on control towers notes that many organisations struggle to answer the basic question: “Where is my shipment? When will it arrive? What’s causing the delay?”

When you have uncontrolled vehicle arrivals, undocumented handoffs, manual GRNs, disconnected ramps and inconsistent bay usage, each is a weak link. Multiply this across multiple sites, multiple lines and multiple shifts, and you get logistics that look modern, but are functionally operating at analog speed in a digital world.

For a manufacturing/logistics leader, that means:

- Idle trucks waiting at gates (wasted money)

- Under-utilised docks (lost capacity)

- Fragmented data flows (paper → SAP → rekey)

- Limited actionable visibility for operations, quality and finance

This isn’t one of those headline-grabbing problems where an AI swoops in and saves the day overnight. It’s quieter and more dangerous- like a slow leak in a giant pipe. The impact shows up not as one big failure, but as a chain of tiny inefficiencies: trucks queuing longer than they should, forms going missing, mismatched entries creeping into SAP, SLAs slipping by a few hours here and there. Add those “little” delays across a few hundred trips a month, and suddenly your costs are spiraling, your productivity graphs are sagging, and your operations team is constantly playing catch-up.

The Problem Statement: Where the pain resides

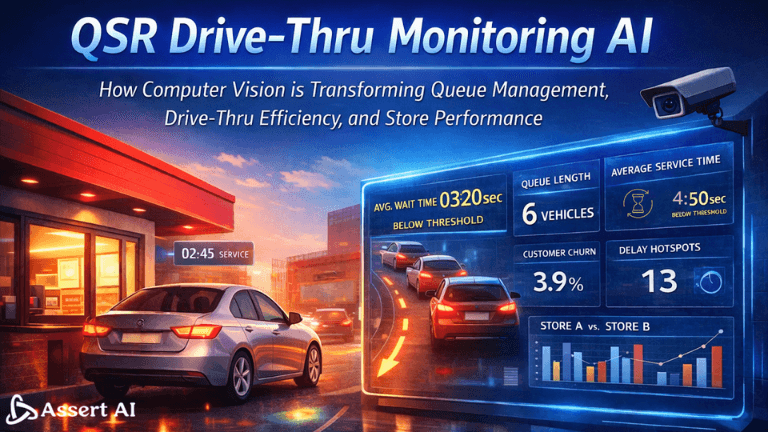

Let’s break down the pain points that AI-powered yard management targets:

- Unplanned and uncontrolled vehicle arrivals at gate – Vehicles sometimes show up early, sometimes late, sometimes without proper PO matching. Manual gate logs result in delays and lack of traceability.

- Manual paper-based checklists & GRN creation – Every receipt of goods, every dispatch, still involves humans walking tyresome steps, writing notes, then keying data into ERP. That introduces latency and risks.

- Offload / load operations without real-time monitoring – Who is on which ramp, how long did unloading take, was there congestion? Without monitoring, you cannot optimise bay utilisation or throughput.

- Lack of integration between physical operations and enterprise systems – The disconnect between handoff, checklist, photo-evidence, GRN in SAP, invoice reconciliation means higher cost of poor quality, missing audit trail, non-standard practices.

- Siloed dashboards and little proactive alerts – Site managers rely on legacy spreadsheets, weekly reports. When something goes off track, it’s already too late.

So operations are handicapped by visibility gaps, manual handoffs and system-fragmentation. This is exactly the kind of problem that AI vision + edge computing + systems integration can tackle.

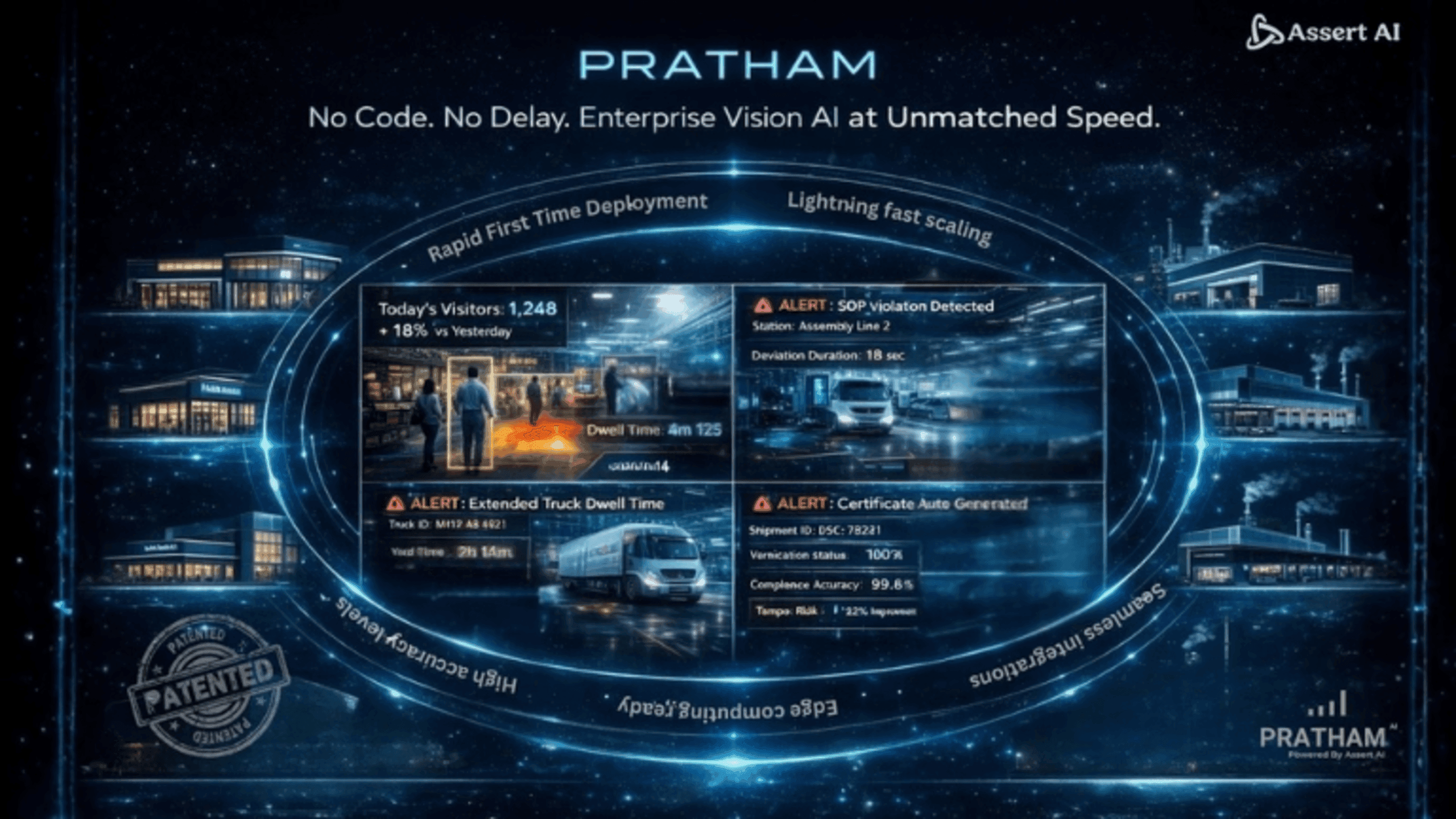

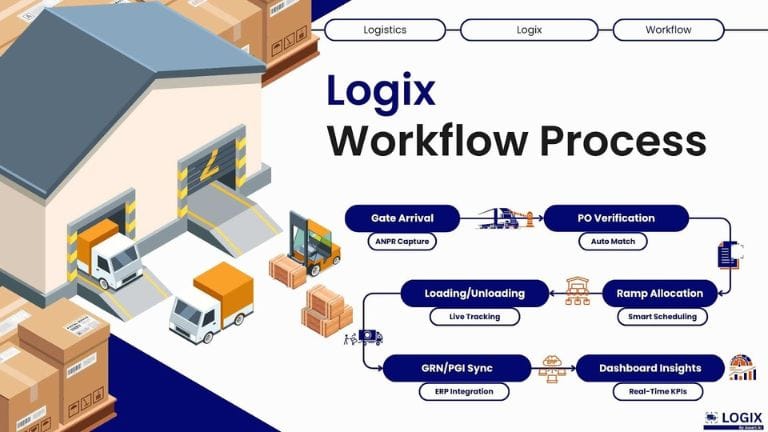

The Solution: Digitising Logistics with Assert AI’s LOGIX Platform

Assert AI’s LOGIX transforms chaotic yards into intelligent ecosystems. By fusing computer vision, edge analytics, and ERP integration, it delivers real-time visibility of every truck, bay, and operation. The platform automates gate entries, tracks load and offload cycles, syncs data directly with enterprise systems, and generates actionable insights; turning hours of manual coordination into seconds of intelligent automation.

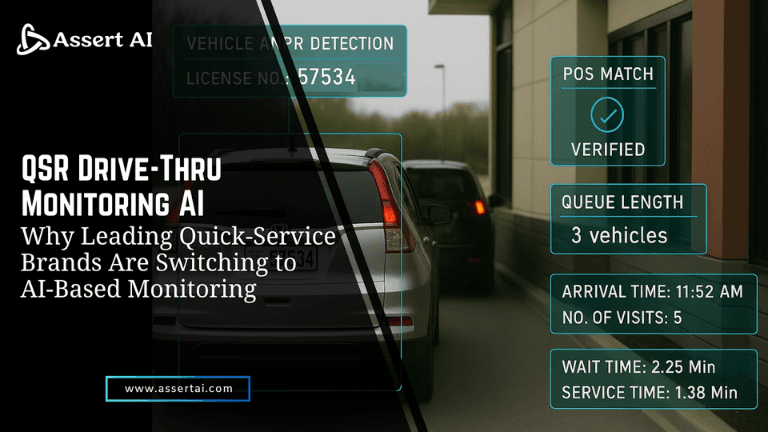

Inbound Delivery & Gate Entry: Pre-booked, pre-verified, digitally tracked

When every inbound vehicle enters the facility with a QR-tagged delivery ID (synchronised with SAP PO). As soon as the truck arrives, the number-plate is captured via ANPR, the inbound ID is verified, the docking ramp allocated automatically. No paper. No “wait until the clerk checks”.

Key benefits:

- Instead of trucks idling at the gate, dwell time reduces significantly (80% reduction in number-plate verification time reported in a similar flow)

- The system ties gate-entry to SAP PO instantly; meaning operations are always aligned with purchase order, no mismatch surprises.

- Ownership and accountability become visible: who verified what, when and where.

Logix by Assert AI delivers real-time visibility and optimisation of dock door scheduling.

Off-loading Workflow: Tablets, Photos, Ramp-Metrics

Once the truck is inside, the action moves to the ramp. A handheld tablet guides the operator: scan the shipment, capture vehicle & product photos, record ramp number, operator ID, offload start time and finish time. Every action is timestamped, geo-tagged, digitally stored.

Why this matters:

- The move from “someone scribbles notes” to “every activity is captured” means traceability and analytics become possible.

- Ramp utilisation metrics emerge: how long a bay sat idle, which ramp is overloaded, where process bottlenecks are persisting.

- Visual proof (photos and short video clips) mitigate disputes/claims and provide audit trail for quality and invoice teams.

Also Read: AI Productivity Tool to Eliminate Manual Gate Logs and Dock Scheduling

Goods Receipt & SAP Integration: One flow, no re-keying, audit-ready

As soon as the offload checklist is validated, the GRN (Goods Receipt Note) is auto-generated in SAP. If the industry requires a Certificate of Analysis (COA) (common in chemical, pharma, food industry), that too becomes auto-linked.

What this gives you:

- Dramatically lower manual errors and mismatch between physical receipt and ERP ledger.

- Transparent audit trail: inbound truck → photo proof → offload checklist → GRN → invoice.

- Faster financial close-out, fewer hold-ups from invoice/quality reconciliation.

Real-time visibility and integrated GRN workflows are core to modern supply-chain control-tower architectures.

Also Read: Beyond the WMS: Why AI in Warehouse Management Is Now Mission-Critical

Outbound Delivery & Loading: Reverse of inbound but with same level of control

It’s one thing to manage inbound; outbound has its own riff: shipping, vehicle loading, dispatch audit, gate-exit. The platform enables: mobile app checklists for outbound pick-pack, photo capture of vehicle loading, instant generation of Post Goods Issue (PGI) in SAP, automatic gate-pass.

Operational payoff:

- Checks and balances built into the outbound process: if a truck tries to leave without checklist completion, the system flags the deviation and exit gate pass is not issued.

- Faster turnaround for outbound trucks, better slot/ramp planning, fewer last-minute scramble for transport teams.

- Visibility of dispatch events for logistics, operations and finance.

Also Read: Minimize Detention and Dock Delays Through Real-Time Warehouse Tracking

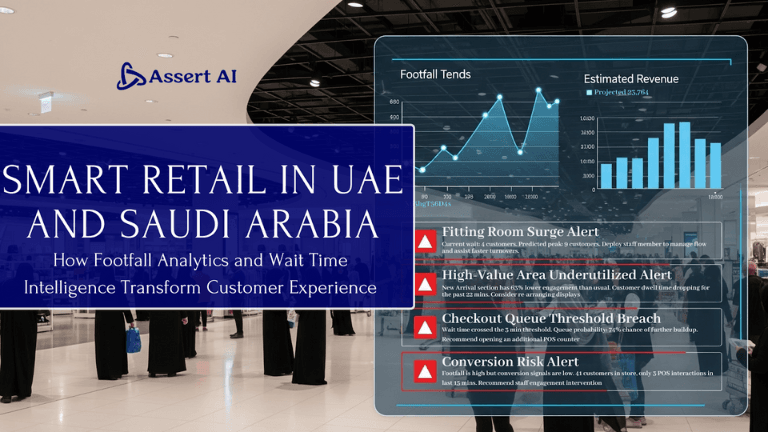

Control-Tower Dashboards, Real-Time Alerts & Analytics: The nerve-centre

The hero’s control room: dashboards that show, site-by-site, the KPIs you care about: truck arrival timeline, average turn-around time (TAT), offload/load durations, ramp utilisation, idle bay percentage, exceptions flagged. Real-time alerts ensure you’re reacting to the red zone before it becomes a crisis.

Metrics-driven value:

- Organisations using AI-enabled control towers report major improvements in decision-making speed and visibility.

- When visibility moves from weekly reports to live dashboards, the cost of errors drops (fewer disputes, fewer manual escalations).

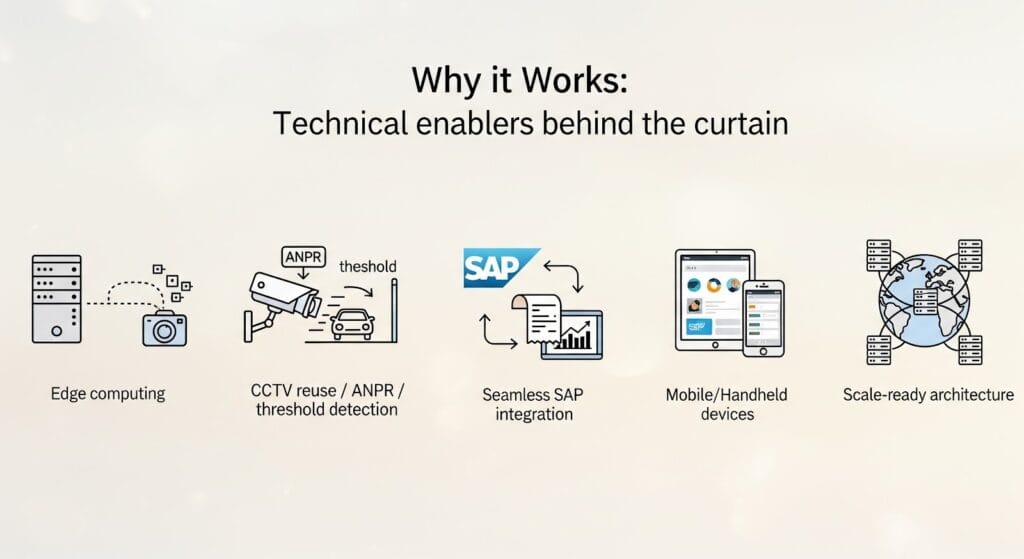

Why it Works: Technical enablers behind the curtain

- Edge computing: The system runs analytics close to the camera/ramp (rather than sending every frame to the cloud). This improves latency, preserves bandwidth, and enables near-real-time decisioning.

- CCTV reuse / ANPR / threshold detection: Rather than deploying massive new hardware, it taps existing infrastructure (where feasible), which means faster roll-out and lower cost of change.

- Seamless SAP integration: Because operations and finance live in the same ecosystem, the hand-over from physical receipt to ERP posting is smooth, audit-ready and scalable.

- Mobile/Handheld devices: With tablets and mobile apps guiding users, the process is standardised, enforced and consistent across sites.

- Scale-ready architecture: Whether you run 1 site or 100 sites across geographies, the platform supports centralised dashboards, regional clusters and local autonomy.

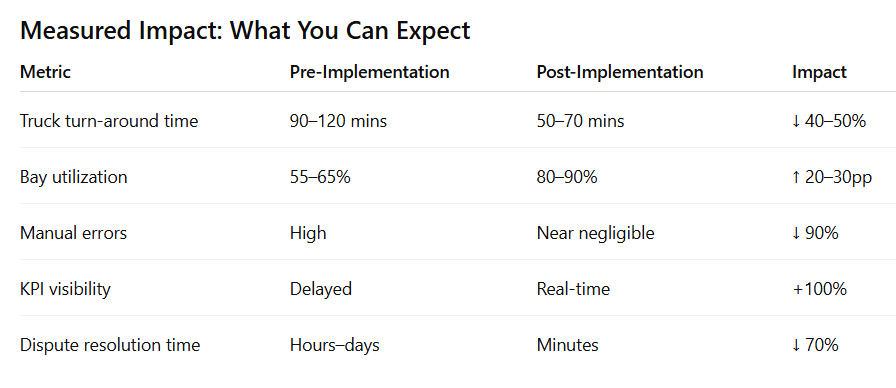

Measured Impact: What You Can Expect

Putting the solution into place is the easy part; the value comes when you start tracking outcomes. Here are typical impact bands you can expect, and these are based on benchmarks and the underlying logic of our platform:

Who Gains and Why It Matters

Operations Leadership

Gain end-to-end logistics visibility from gate entry to dock dispatch and multi-site warehouse monitoring. With AI-powered analytics and real-time data, operations managers can shift from reactive firefighting to predictive planning, improving throughput and on-ground coordination.

Logistics Teams

Experience fewer disruptions, smoother handovers, and reduced turnaround times. With AI vision–driven yard management, ramp idle time decreases, truck queue lengths shorten, and loading–unloading schedules become data-backed and precise.

Finance & ERP Teams

Automated Goods Receipt Note (GRN) to invoice validation ensures higher accuracy. Every transaction is traceable with a verifiable digital audit trail, minimizing manual errors and reducing invoice disputes through seamless ERP integration.

Quality & Compliance Teams

Get digital photo logs, video-based process validation, and traceability reports, making documentation effortless and regulatory compliance consistent. Every step of your dock and warehouse operation is recorded for transparency and audit readiness.

Business Leadership

When logistics directly impacts cost, customer experience, and operational risk, AI and edge computing in yard logistics become a strategic differentiator. Deploying computer vision analytics helps leadership gain real-time control, efficiency insights, and strategic agility across the supply chain.

The shift to AI-enabled logistics operations isn’t optional, it’s imperative if you are managing high-volume facilities, complex inbound/outbound flows, multi-site operations across geographies and tight SLAs.

Your chance is to take what appears to be an operational cost centre and turn it into a performance differentiator. So you have less wait time for trucks, fewer errors, enhanced throughput, tighter alignment between operations and ERP, and real-time control.

From reactive to real-time: that’s the leap LOGIX enables.

If your operations are still defined by clipboards, gate queues, and manual reconciliations, it’s time to hit reset. With Vision AI and edge computing, logistics doesn’t have to be a daily juggle; it can be a data-driven advantage.

👉 Start your yard’s transformation today.. because visibility is profitability.