“If you don’t have time to do it right, when will you have time to do it over?”

– John Wooden

Manufacturers across industries understand that quality checks in manufacturing go beyond catching defects; they play a critical role in preserving brand reputation, ensuring customer satisfaction, and protecting profit margins.

But here’s the catch: Manual inspections, even with the best-trained eyes, aren’t enough anymore. Modern assembly lines are faster, more complex, and often serve customers with zero tolerance for errors.

And the numbers back this up: According to the American Society for Quality (ASQ), the cost of poor quality (COPQ) for manufacturers can range from 5% to 30% of gross sales. In industries like automotive and aerospace, one misassembled kit can cost thousands of dollars in rework or warranty claims.

(Source: ASQ, Manufacturing Quality Report)

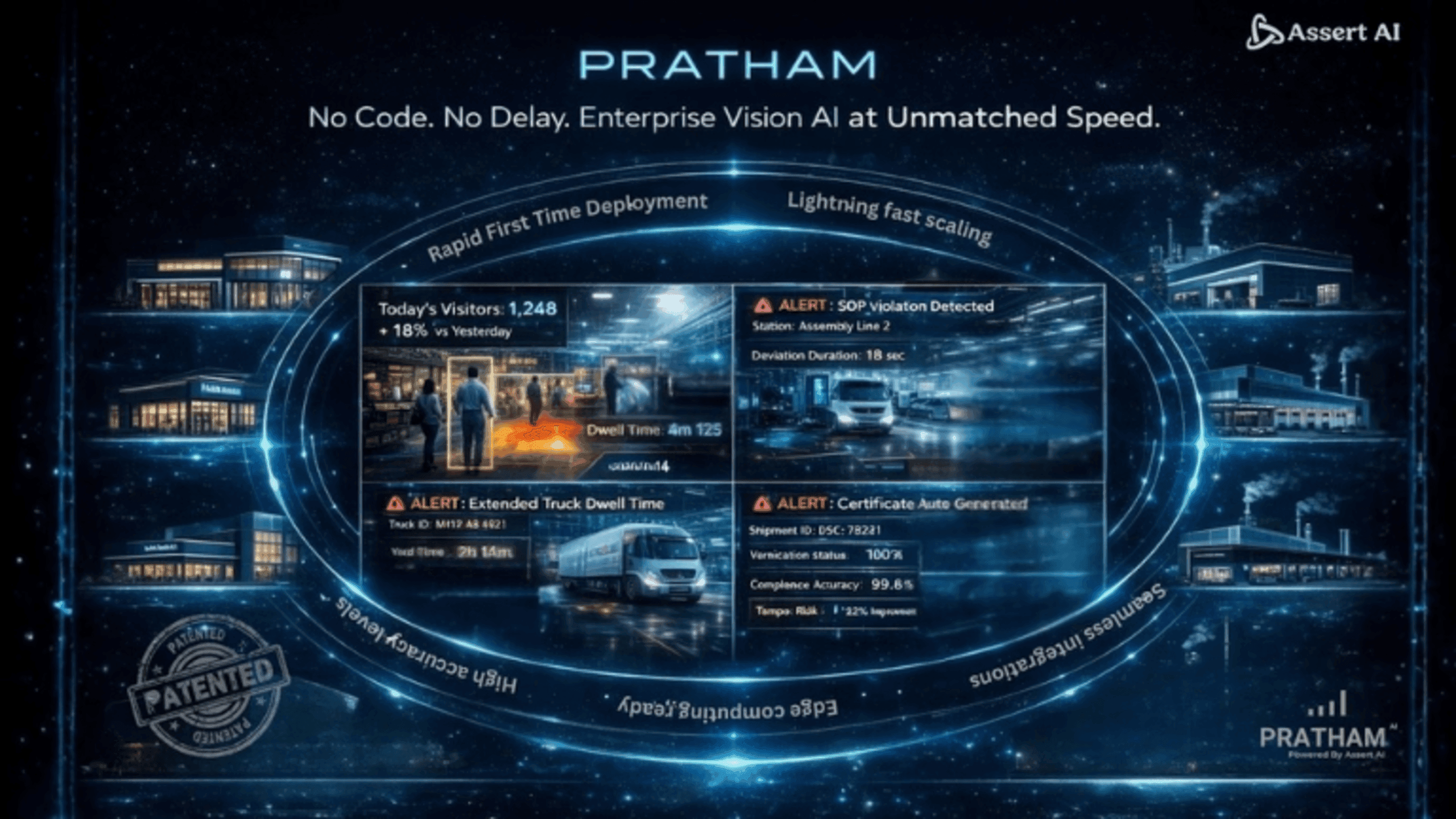

A McKinsey study estimates that AI-driven quality control can reduce manufacturing costs by up to 20%, translating to billions in savings globally. Meanwhile, global investment in AI for manufacturing is expected to reach $16.7 billion by 2026, with quality control being a major application area (Source: IDC, 2021).

No matter what you manufacture- from turbine blades to foam panels, plumbing kits to electronic assemblies- product quality checks can no longer be an afterthought.

Here’s how computer vision is changing the game.

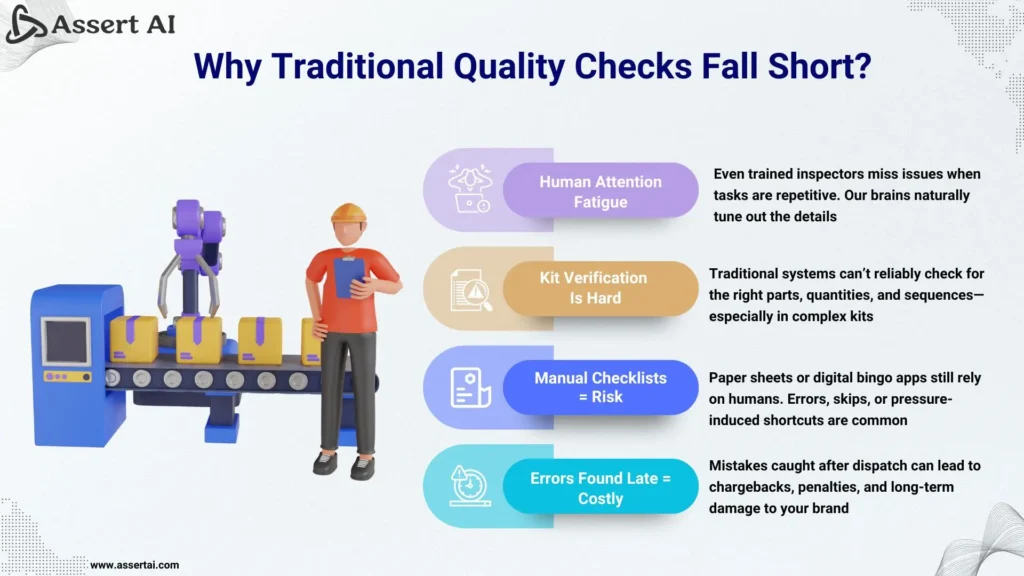

Why Traditional Quality Checks Fall Short

Even the most experienced inspectors can fall prey to the monotony of repetition. Day after day, part after part- when your eyes see the same thing over and over, your brain starts to blur the lines. It’s not a lack of skill, it’s human nature. That’s how a defective product slips by, or how a kit, meant to have say 15 specific components goes out the door missing two critical parts.

In factories around the world, especially those assembling kits or products, the system is often built to spot what’s wrong– a crack, a dent, a missing label. But what about checking what’s right? Verifying that every piece is present, in the right quantity, and in the right sequence? That’s where traditional systems and human attention start to break down.

Many manufacturers still trust paper-based checklists or “bingo sheets” to confirm kit contents. But these can be misread, skipped, or even manipulated under time pressure. Even digital apps that replace paper forms, while better, are still vulnerable to human oversight or error.

And when an issue is found after dispatch? The damage isn’t financial alone. Chargebacks, penalties, and retail deductions- it’s reputational. One faulty shipment can cost far more than money. It costs trust.

Manufacturers are waking up to this reality. According to a PwC survey, 27% have already integrated AI in quality control, and another 37% are planning to follow suit within the next three years. Because the cost of not catching mistakes in time is one most companies can’t afford to keep paying.

Real-Time Assembly Guidance: Making Manufacturing Smarter

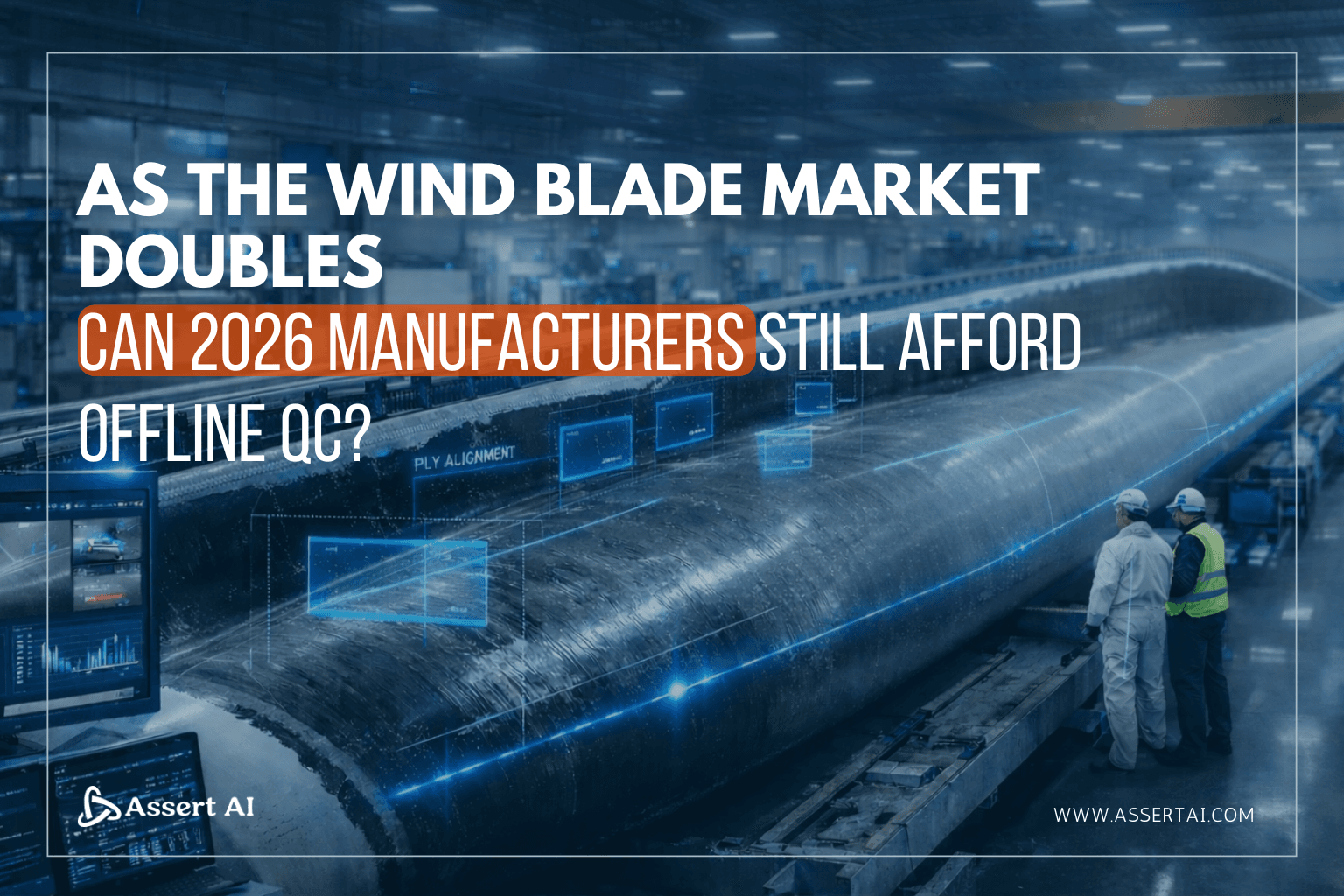

In industries like aerospace and composites manufacturing, precision is everything. One misplaced ply, one incorrect component, and an entire structure can fail inspection or, worse, fail in real-world operation.

A leading composite manufacturer has implemented laser projections combined with computer vision to guide operators during ply placements. Using OCR, the system identifies the right ply based on printed labels, ensuring accurate selection from a large set. Cameras verify in real time that the correct number of plies are used, that each ply is positioned in alignment with tolerances, and that operators are following sequence as per PQPR (Product Quantity Process Routing), which doubles as a quality control checklist for manufacturing.

The results speak for themselves. Scrap reduction improved by 20-30%, while compliance with industry standards has become more predictable and consistent. What’s more, the combination of laser guidance and visual monitoring ensures proof-of-process for regulatory and customer audits, building long-term confidence in the manufacturing operation.

Precision Kitting: No Missing Parts, No Extra Costs

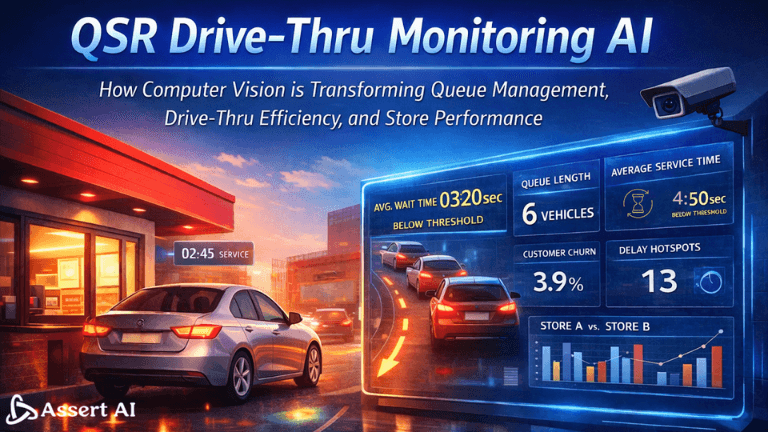

Whether it’s foam panels for wind turbines or plumbing assemblies, kitting errors result in production delays downstream. Missing parts mean entire assembly lines at the customer’s site can grind to a halt.

For instance, in the composite material industry, manufacturers kit foam panel sets for delivery to global OEMs. Traditionally, a manual bingo sheet is used to cross-check parts before shipment. But human fatigue, rushed schedules, and high SKU complexity lead to frequent errors.

With computer vision integrated into the process, cameras monitor the kitting workstation in real-time. Each part is verified automatically against the digital PQPR document or quality control checklist for manufacturing. The moment something’s missing, duplicated, or incorrect, the system generates an immediate alert.

More importantly, the system also generates a Digital Shipping Verification Certification (with video evidence), ensuring that what was packed is exactly what was dispatched. This serves as legal proof against customer disputes, helping manufacturers avoid lawsuits, penalties, and expensive reshipments.

The payoff? Many manufacturers report a 95% reduction in incomplete kit shipments, saving thousands annually on emergency reshipments, penalties, and retail deductions.

Globally, AI-powered visual inspection systems can detect defects with up to 90% accuracy, compared to 50% for traditional methods (Source: McKinsey, 2019).

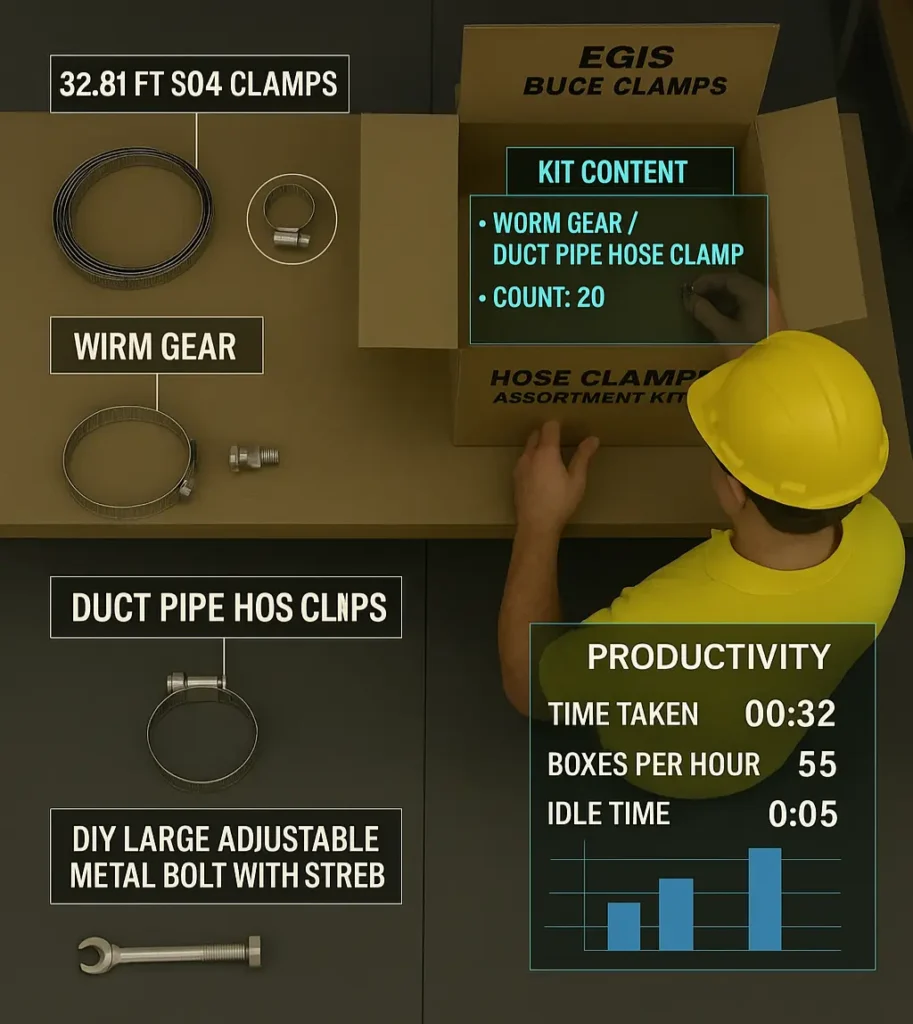

Workstation Monitoring: Boosting Productivity and Accuracy

Manual processes suffer from quality errors and create blind spots in productivity.

Consider the example of a plumbing manufacturer where kits often include dozens of small components. By installing cameras at each workstation, they’re now able to track assembly sequence accuracy, detect if any components are missed or duplicated, and monitor time taken for each kit to be completed.

This visibility is priceless. The data helps operations teams highlight bottlenecks, plan better staffing, and identify training needs. Over time, businesses have seen productivity improvements of 15-20%, and more accurate reporting during audits and reviews.

Additionally, AI can reduce inspection time by up to 80%, freeing up human inspectors for more complex tasks (Source: Capgemini, 2020).

Dispatch Verification: The Last Line of Defense

Mistakes caught before dispatch prevent costly downstream problems. Final camera scans ensure kit contents match shipping and order documents. Generating Digital Shipping Verification Certificates for customer records doesn’t just prevent disputes; it reassures customers and partners that your quality control process is thorough.

For industries like automotive, aerospace, electronics where accuracy matters most, this can be the difference between being a preferred supplier or being cut out of future contracts.

The benefit extends to preventing penalties, chargebacks, or damaged relationships from incorrect deliveries, while reinforcing long-term customer confidence in your operational capability.Moreover, lower production costs resulting from fewer defects and scrap rates can lead to a 10-20% decrease in manufacturing costs (Source: PwC, 2018).

What’s the ROI of Smarter Quality Checks?

Improving inspection and quality control in manufacturing isn’t only about process improvement, it’s about protecting overall profitability.

Global manufacturers lose over $1 trillion annually due to product recalls, rejections, and returns, according to estimates by the World Economic Forum and McKinsey. These losses stem not just from defective products but also from penalties, damaged reputation, and lost future sales.

Across the industry, AI can optimize production processes, leading to a 10-15% increase in throughput (Source: Deloitte, 2019) and a 20-50% improvement in overall product quality (Source: Forbes, 2021).

Beyond this, companies have seen potential 5-8% revenue growth due to improved throughput and fewer product returns or penalties.

Customers notice when you get it right consistently. That translates into more orders, better partnerships, and long-term contracts.

FAQs About Computer Vision for Quality Checks

Will this replace our quality inspectors?

No. Computer vision supports human workers by automating repetitive, error-prone tasks, freeing up inspectors to focus on high-skill, specialized checks.

What if we have highly customized orders?

Computer vision works even better with customization. It tracks specific orders, not just generic templates.

How hard is it to integrate?

Many systems can integrate with existing CCTV setups. Digital PQPRs and shipping records easily sync with modern ERP solutions.

Does this only work for large manufacturers?

No. Even small and mid-sized manufacturers benefit significantly from reducing shipping errors, improving throughput, and cutting operational costs.

What are manufacturers using AI for today?

According to Gartner (2021):

- 60% use it for predictive maintenance

- 50% use it for visual inspection

- 40% use it for process optimization

It’s Time to Make Quality Count

No matter what kind of manufacturing setup you have-

- Manual assembly → risk of human error

- Semi-automated lines → gaps in verification

- Complex kitting → high chances of mismatches

Computer vision fills the gaps. It turns quality checks into proof-based processes, providing both operational reliability and legal protection.

Want to see how it works? Start with a walkthrough or a pilot project tailored to your needs.

Sources:

- ASQ Manufacturing Quality Reports: https://asq.org/quality-resources/cost-of-quality

- Deloitte Smart Factory Study 2023: https://www2.deloitte.com/us/en/pages/manufacturing/articles/the-smart-factory.html

- McKinsey, PwC, IDC, Gartner, Forbes, Capgemini Reports cited above

Related Reads: ➡️ Beyond Destructive Testing: How AI Vision is Reinventing Quality Control in Composite Manufacturing