From Gut-Feel to Ground Truth with AI for Time Management

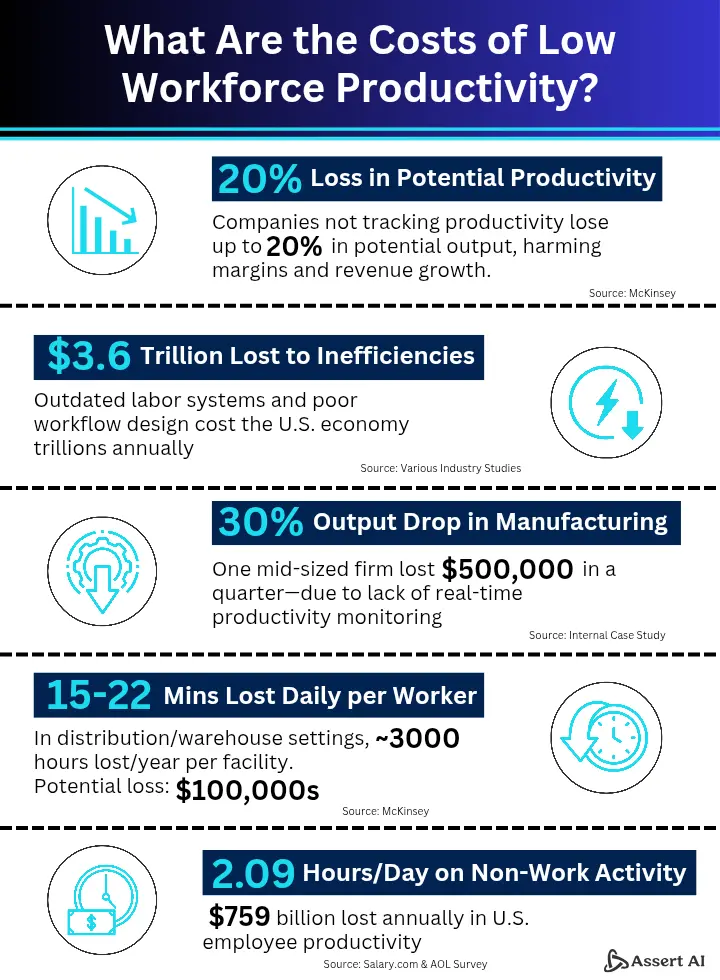

The difference between a profitable line and a struggling one often lies in how well time and throughput are managed on the shop floor. But even today, manufacturers are forced to rely on manual tracking, subjective observations, or siloed digital systems to answer basic operational questions: How long did a workstation stay idle? Was assembly work happening during that shift? Did we meet target output or fall behind?

That’s where AI for time management steps in: bringing data-backed visibility, automation, and real-time clarity to every second spent on the floor.

When Visibility Is Missing, So Is Control

In a typical manufacturing plant, everything looks fine, until it isn’t. A line falls behind schedule. A workstation sits quiet longer than it should. Materials seem to appear late, or worse, go unnoticed when missing. The issue isn’t always the process itself, sometimes it’s the lack of real-time visibility into what’s actually happening on the floor.

Take, for instance, operator presence. If there’s no live view into whether a station is manned or not, you may never know if a delay was due to labor unavailability or a misaligned schedule. Over time, such blind spots add up, leading to uneven workloads and productivity dips that appear inexplicable on paper.

Similarly, material flow is often assumed rather than verified. Without knowing whether components have actually arrived at a work table on time, managers are left guessing when cycle times start slipping. Delays in material readiness silently chip away at output, causing schedule overruns and cost escalations that go untraced.

Even more elusive is the difference between looking busy and actually working. Manual observation can’t always tell if assembly work is genuinely in progress or if a station is functionally idle. This disconnect between perceived and actual productivity can skew performance metrics, masking deeper inefficiencies.

And then there are the unsung heroes of production: the material carts. These mobile carriers often determine whether a task starts on time or is stuck in limbo. One missing cart during a shift change can trigger a domino effect across multiple stations, yet without proper tracking, the root cause remains buried.

In all these cases, the common thread isn’t human error, it’s the absence of reliable, real-time data. When critical events on the shop floor go unseen or unlogged, decision-making becomes reactive instead of proactive. Delays become routine, daily stand-ups become guessing games, and managers are left putting out fires instead of improving throughput.

Assert AI’s vision-driven insights aim to change that narrative.

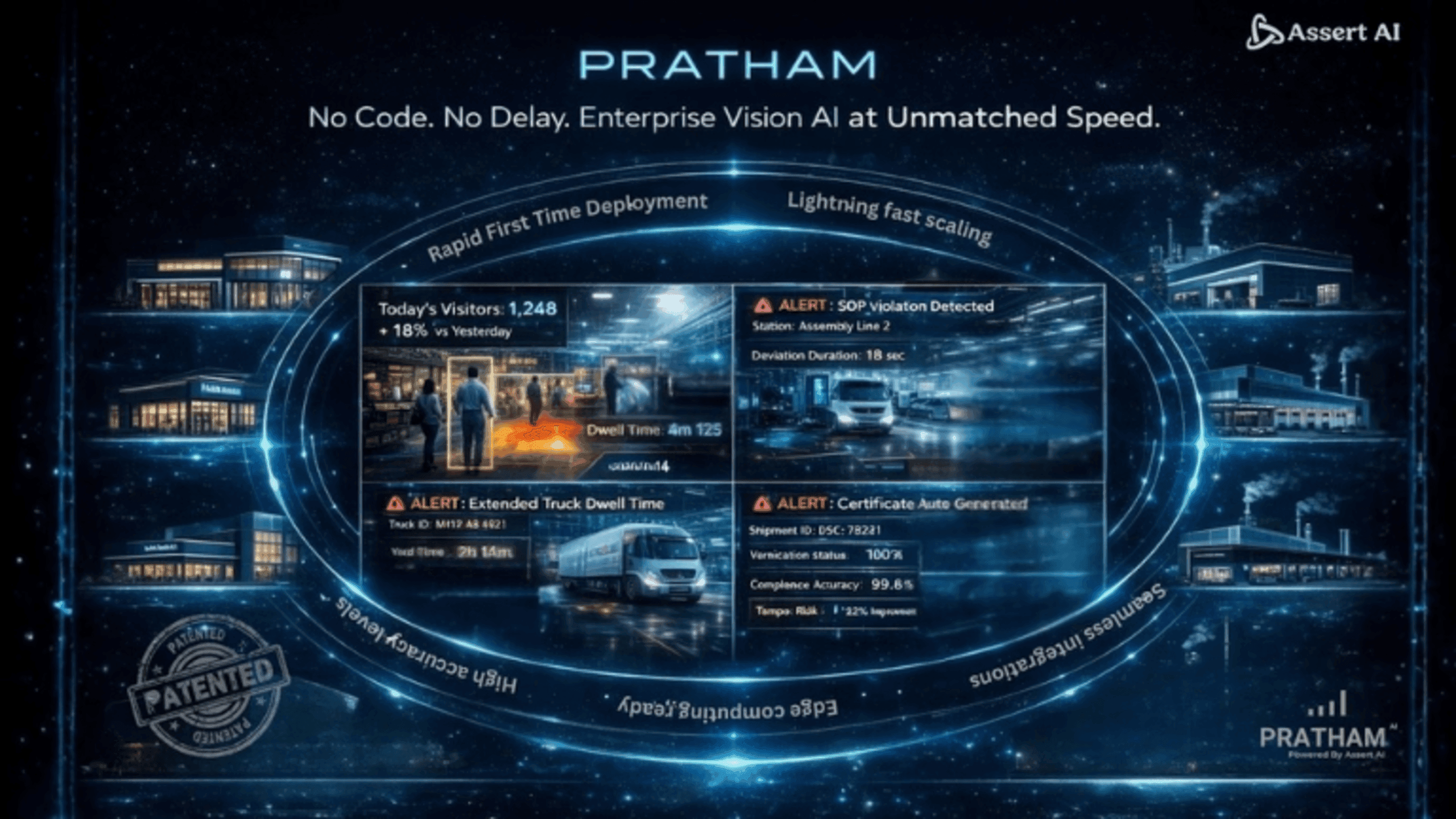

By turning existing camera infrastructure into intelligent observers, Assert AI enables manufacturers to unlock ground truth from every corner of their shop floor. Our platform brings together AI for time management and AI productivity tools into one seamless ecosystem, giving teams real-time answers to questions that previously took days (or never surfaced at all).

What Gets Measured, Gets Improved – And Scaled

Modern manufacturing thrives on data. Assert AI’s computer vision platform transforms everyday video feeds into powerful productivity intelligence- non-intrusively, across multiple factory floors. These metrics not only paint a clear picture, they expose the invisible bottlenecks, highlight top performing zones, and bring operational clarity in real time.

🔍 High-Impact Metrics That Drive Smart Decisions

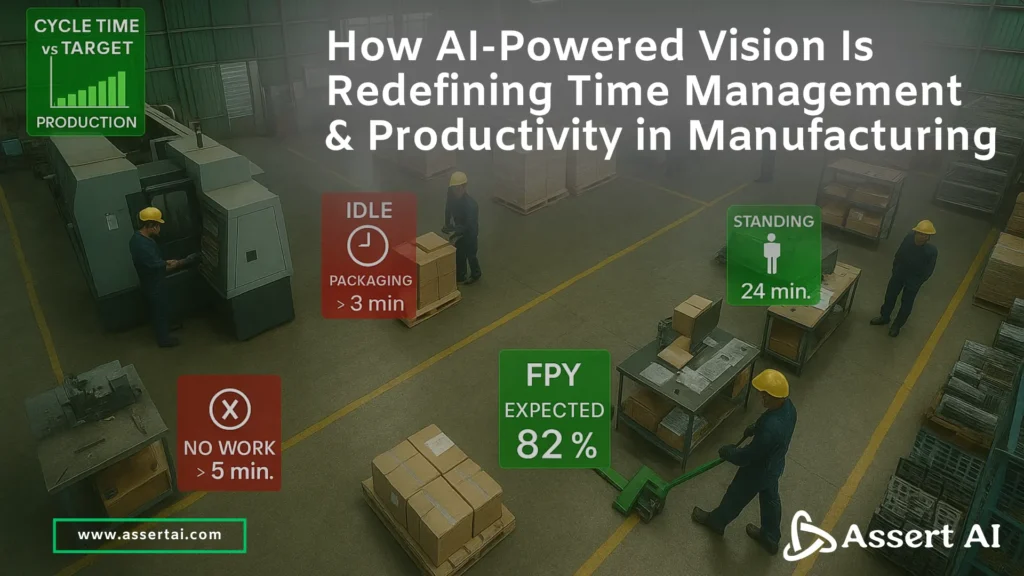

1. Work Cell Status (Active / Idle / Blocked)

Go beyond assumptions. Know exactly when a station is productive, waiting, or stuck. This helps allocate resources and redesign workflows intelligently.

2. Part Count Output

Precision part-counting from camera feeds with no manual counting, no under- or over-reporting. Just consistent, objective output monitoring.

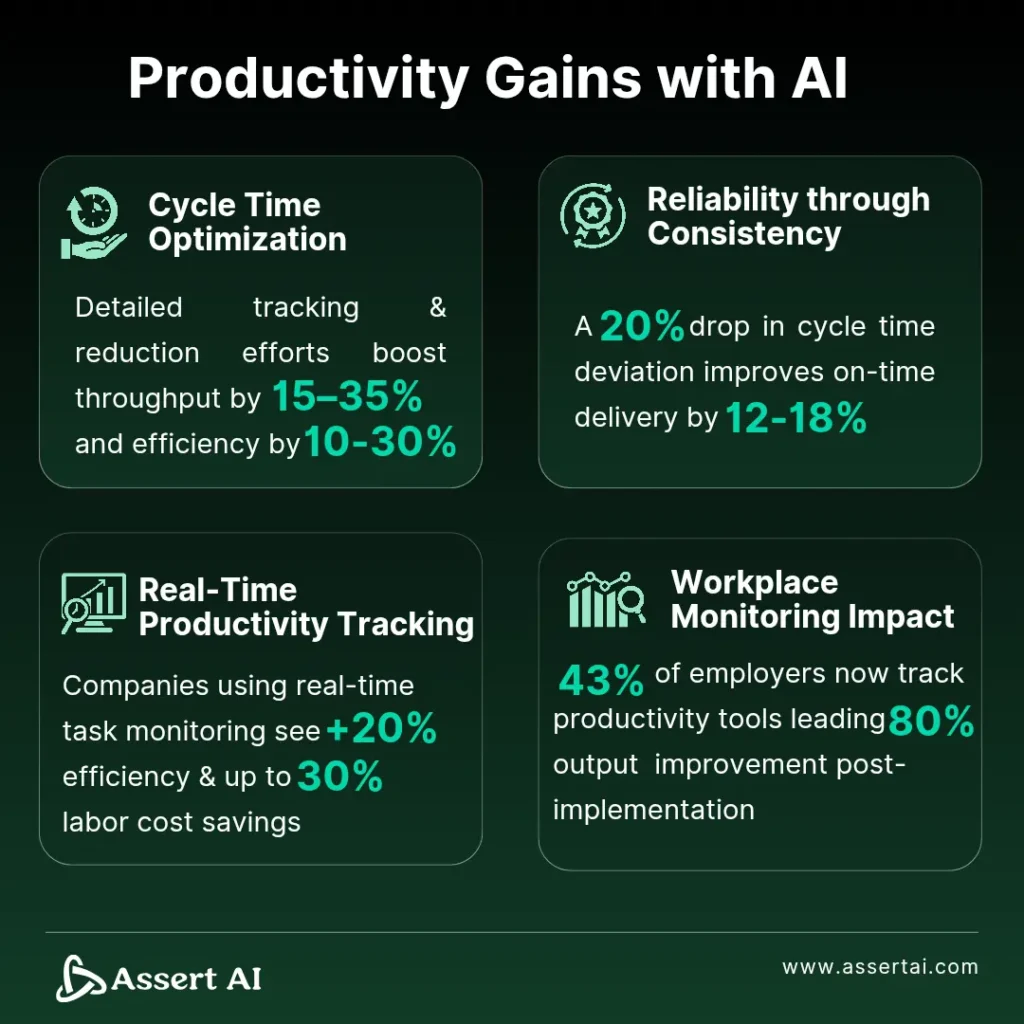

3. Cycle Time & Variance Analysis

Track standard cycle durations and flag when operations begin trending longer. Granular variance breakdown shows whether delays stem from material issues, manpower, or station overload.

4. Station Readiness Index

Capture indicators like material availability and operator presence to quantify how “ready” a workstation is before it even starts a job.

5. Micro-Stoppage Tracking

Short halts (5-30 seconds) often go unrecorded. We log them precisely, revealing hidden inefficiencies that traditional systems ignore.

6. First Pass Yield Estimates

By correlating station activity with downstream quality checks, gain predictive insights into FPY without waiting for final QA reports.

7. Multi-Site Benchmarking Dashboard

Compare productivity across locations. Uniform visual data from all facilities flows into a centralized, intuitive dashboard; allowing plant managers and leadership to track, benchmark, and scale best practices globally.

8. Operator Engagement Patterns

Non-invasively measure active engagement time and transitions without ever needing facial recognition or personal tracking. Respect for privacy is baked into the system’s design.

9. Historical Trend Charts & Root-Cause Snapshots

Understand “what changed and when.” With timeline-based video-backed analytics, you get clear causality, not just data trails. Ideal for production reviews, quality audits, and continuous improvement programs.

Integrated. Intelligent. Immediate.

What makes Assert AI’s solution truly next-gen is not just the insights, but how easily we integrate with existing MES, ERP, and OT systems. We’re built to plug into your current architecture; whether you’re using SAP, Oracle, or a custom dashboard. Our APIs, video cue logs, and real-time alerts are designed to enrich, not replace, your current processes.

The result? Data that flows into your central command system, creating a feedback loop where SOPs, manpower planning, maintenance scheduling, and shift performance reviews are all grounded in evidence, not assumptions.

Industries That Benefit from Vision-Led Productivity Insights

From furniture and fixture manufacturing, to automotive component assembly, consumer appliance production, and even specialized equipment fabrication, vision-based productivity tracking offers a transformative edge. Plants with high human-machine interaction, semi-automated lines, or dynamic workstations stand to gain the most.

Operators feel less micromanaged and more supported. Supervisors get clarity without chasing paperwork. Leaders gain strategic visibility to benchmark across plants, lines, or even geographies.

And here’s the best part- the same camera infrastructure can also be used to deploy our AI Quality Monitoring modules, helping improve First Pass Yield without requiring additional sensors or manual QA overhead. One system. Multiple solutions. Maximum return.

It’s Time to Rethink Time

Time management in manufacturing can no longer be left to spreadsheets, static reports, or anecdotal feedback. With AI for time management powered by vision, Assert AI delivers unmatched visibility into how time, people, and materials move through your shop floor.

We help you not just see delays, but understand them. Not just track productivity, but improve it. And ultimately, build a plant that works as smart as your team does.

If you’re ready to make every minute count, it’s time to bring vision to your operations.

🔍 Ready to See Where Your Time Really Goes?

Book a quick demo to discover how Assert AI’s Vision-Powered Time Management can transform your shop floor into a smarter, faster, and more efficient operation.👉 Schedule Your Demo Now