The Problem with Traditional WMS: Blind Spots in the Warehouse

For decades, Warehouse Management Systems (WMS) have been the backbone of distribution and inventory control. These systems track the movement of goods, optimize picking routes, and update stock levels based on human inputs barcode scans, RF guns, and manual log entries. However, without AI-powered warehouse analytics, these traditional systems still leave critical blind spots, limiting real-time decision-making and operational agility. But here’s the core issue: traditional WMS platforms only know what they are told.

If a worker mis-scans a pallet, forgets to scan at all, or inputs incorrect data, the WMS blindly accepts it. This “garbage in, garbage out” model creates fragile operations dependent on perfect execution which, in the real world of high turnover, fatigue, and complexity, is rarely achieved.

According to a study by the Georgia Institute of Technology, 60% of warehouse inventory errors can be traced back to manual processes and human error.

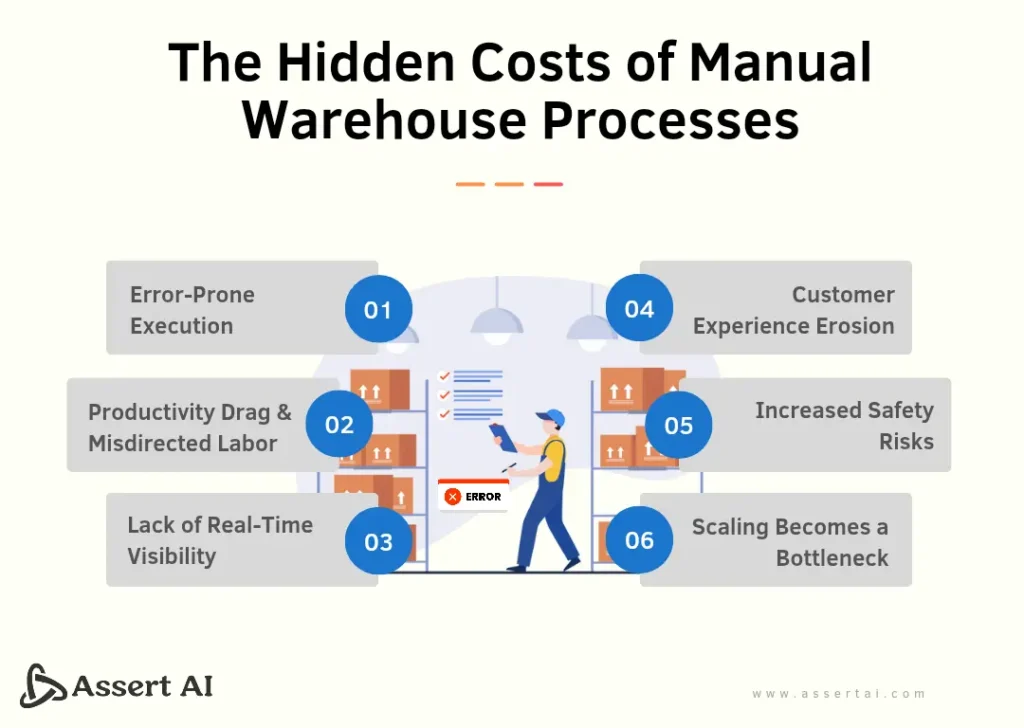

The Hidden Costs of Manual Warehouse Processes

While many warehouses still rely on manual scans, paper logs, and operator input, these processes introduce significant operational risks that compound as the business scales. Here’s what traditional methods are really costing your operation:

🧯 Error-Prone Execution

Manual tasks from scanning and labeling to entering data are inherently vulnerable to human error. A mistyped SKU or misplaced pallet can create a chain reaction of delays, incorrect shipments, and lost productivity. These seemingly small mistakes lead to massive inventory inaccuracies.

🐢 Productivity Drag & Misdirected Labor

When systems are running on inaccurate or outdated data, workers are routinely dispatched to pick from empty shelves or hunt for inventory that’s been incorrectly placed. The result: wasted labor hours, reduced pick rates, and mounting frustration on the warehouse floor.

🔍 Lack of Real-Time Visibility

Without continuous, automated validation, you don’t actually know where items are at any given moment; you only know where the WMS thinks they are. This disconnect leads to mispicks, delayed order fulfillment, and a reactive operations culture.

💥 Customer Experience Erosion

Stock inaccuracies and fulfillment delays quickly surface downstream directly impacting the customer. Missed orders, late deliveries, and stockouts increase the likelihood of failed SLAs, backorders, and ultimately lost trust in your brand.

⚠️ Increased Safety Risks

Manual handling of heavy or high-frequency tasks increases the risk of injury. As staff work around outdated processes or inefficient layouts, they’re more likely to cut corners or take unsafe shortcuts under pressure.

🧱 Scaling Becomes a Bottleneck

As volume grows, manual processes become unsustainable. Hiring more staff isn’t always viable and scaling without visibility compounds the chaos. What worked in a 10,000 sq. ft. warehouse quickly breaks down in a 100,000 sq. ft. operation.

✅ The Solution: Augmenting Your WMS with AI in Warehouse Management

Every one of these challenges- accuracy, speed, safety, and scalability ties back to visibility. And visibility doesn’t come from reports or dashboards alone. It comes from real-time, AI in Warehouse Management drives verification of what’s actually happening on the warehouse floor.

A report by Deloitte found that 79% of supply chain leaders cited lack of real-time inventory visibility as a top challenge impacting decision-making and operational efficiency.

The AI Layer: Turning a WMS into a Real-Time Truth Engine

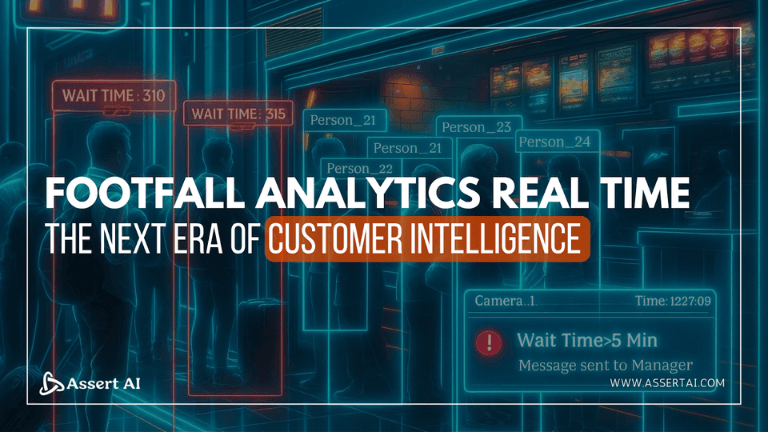

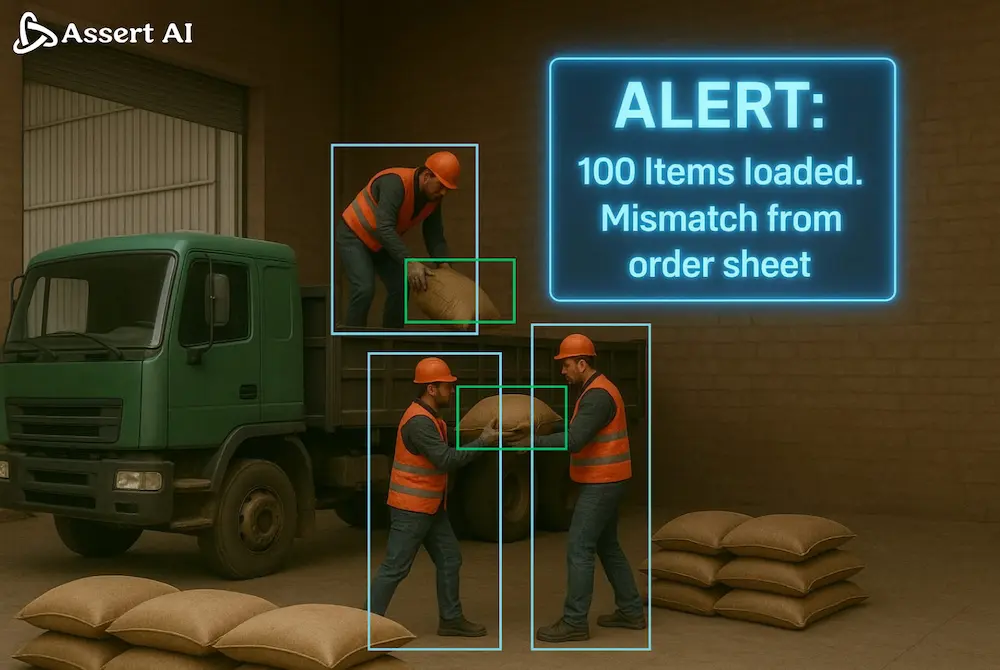

AI isn’t replacing your WMS, it’s making it smarter. Specifically, computer vision and machine learning create a “visual verification layer” that sees what’s really happening in your warehouse.

This vision-based layer continuously monitors loading docks, staging areas, and storage locations using smart cameras and edge AI. It verifies pallet placements, counts, and movements and flags discrepancies in real time, not during a weekly audit.

Here’s how AI in Warehouse Management augments your WMS:

✅ Verifies that scanned items actually match what was picked or placed

✅ Detects missing or misrouted inventory automatically

✅ Validates actions (e.g., loading, putaway) against WMS records

✅ Feeds accurate data back into your WMS without extra labor

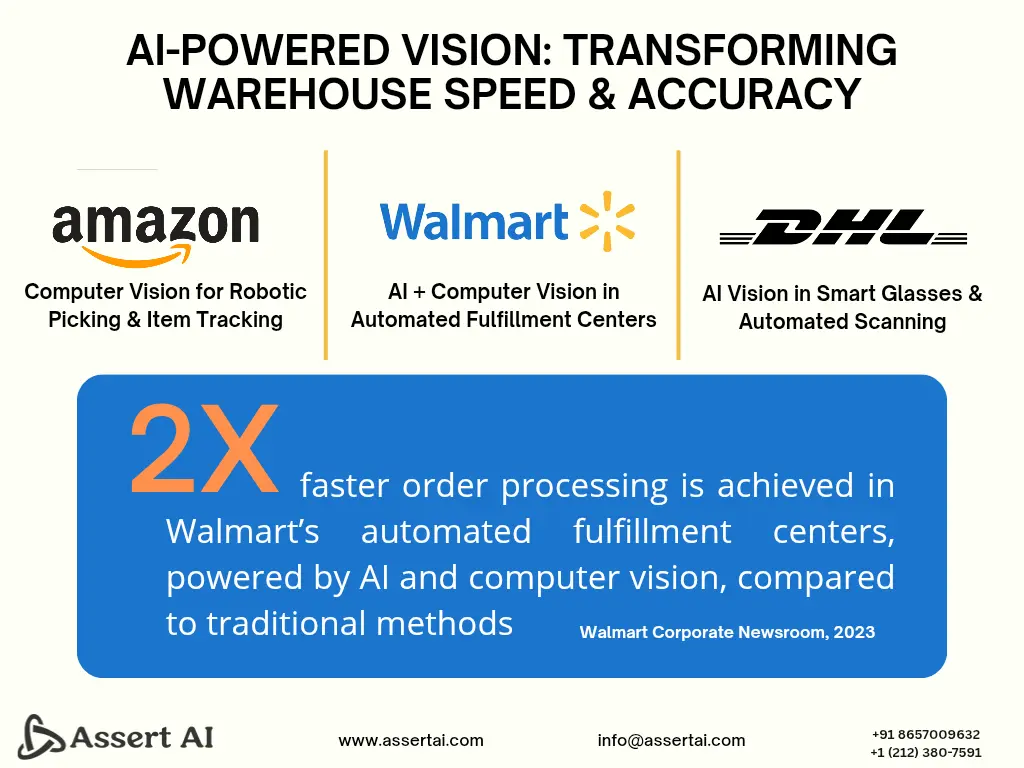

Companies like Walmart, Amazon, and DHL Supply Chain are already using AI-powered vision systems to transform warehouse operations. Walmart’s automated fulfillment centers, powered by AI and computer vision, process orders up to 2× faster than traditional methods (Walmart Corporate Newsroom, 2023).

Real-Time Visibility ≠ Real-Time Dashboards

Many WMS providers advertise “real-time dashboards” but those are only as real-time as the data fed into them. If you’re still relying on barcode scans and human input, you’re watching a delayed, potentially incorrect version of reality.

True real-time visibility means your system has eyes and those eyes are powered by AI:

- Live object detection

- Event-driven alerts (e.g., a pallet skipped QA)

- Autonomous discrepancy detection

- Continuous validation against WMS data

By 2027, 50% of companies with warehouse operations will leverage AI-enabled vision systems to replace traditional scanning-based cycle-counting processes, according to Gartner, Inc.

Also Read: 7 Common Retail Chargeback Mistakes Suppliers Make (and How Computer Vision Can Solve Them)

WMS Alone Is No Longer a Competitive Advantage

Your WMS is a necessary foundation but it’s not a source of truth. Without AI in Warehouse Management there is no enhanced visibility, and you’re running blind in a high-stakes environment.

In today’s ultra-fast supply chains, you need systems that can see, think, and act, not just record.

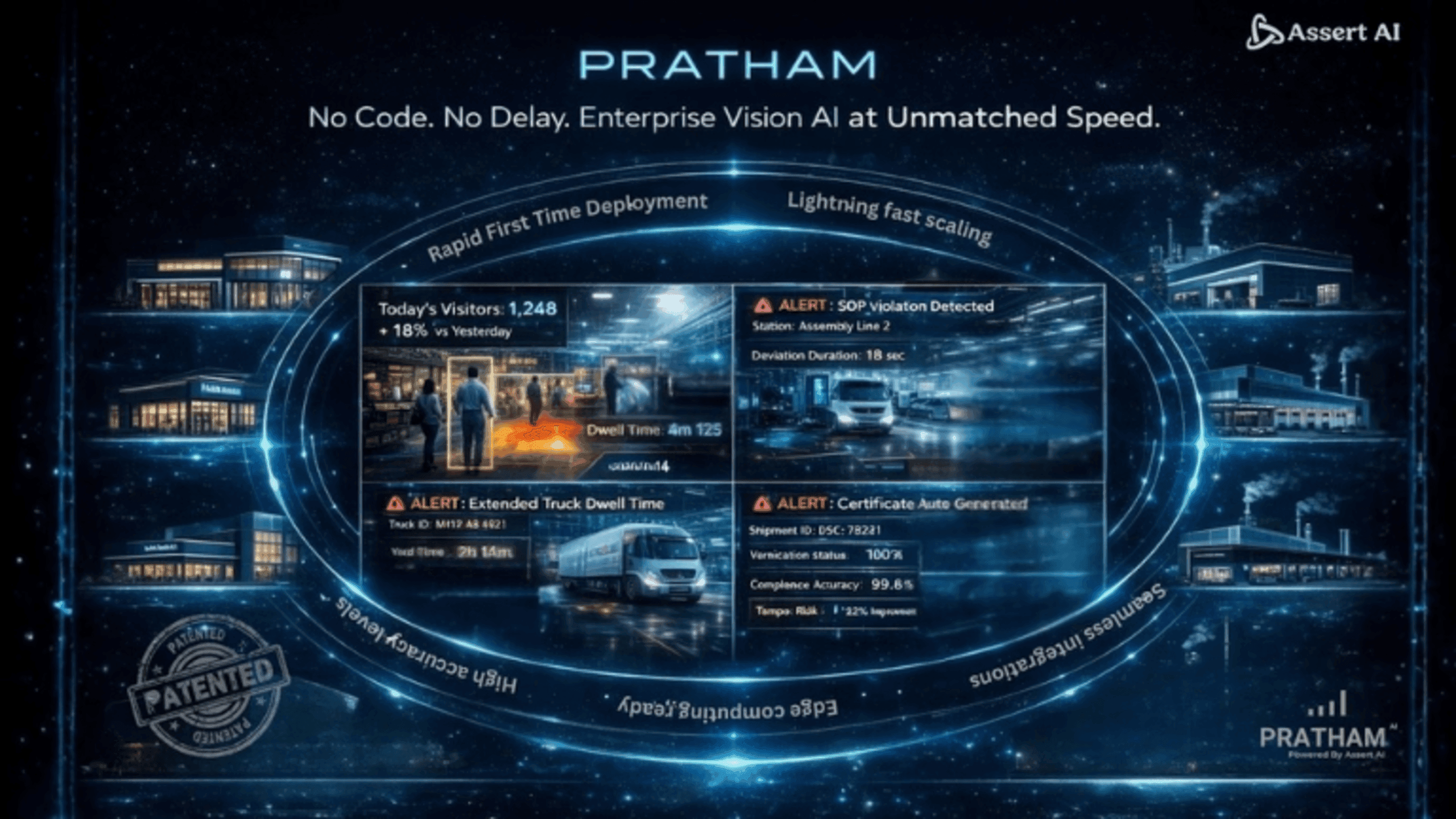

🚀 The Assert AI Advantage

Assert AI equips warehouses with cutting-edge computer vision solutions that work seamlessly alongside your WMS delivering real-time truth, reducing errors, improving safety, and unlocking operational agility. With deployments across India, USA, KSA, and UAE, and trusted by industry leaders, we turn your warehouse into a visibility powerhouse.

Don’t just manage your warehouse see it in action.

📩 Talk to our experts today and discover how Assert AI can make your warehouse faster, safer, and smarter in real time.