Businesses across India, North America, and the Middle East are increasingly turning to Assert AI’s solutions to transform how they operate, safeguard their workforce, and deliver superior outcomes. From warehouses to factory floors, and from retail spaces to drive-thru counters, Assert AI is helping organizations monitor, analyze, and optimize operations in real time- all from a single, integrated platform.

Driving Measurable Impact Across Industries

Assert AI has emerged as a trusted partner to organizations in warehousing and logistics, manufacturing, retail, QSRs, and drive-thrus, where efficiency, safety, and customer experience directly influence profitability. The company’s AI computer vision solutions are designed not as add-ons, but as core enablers of transformation- bringing measurable benefits that clients can track on the ground:

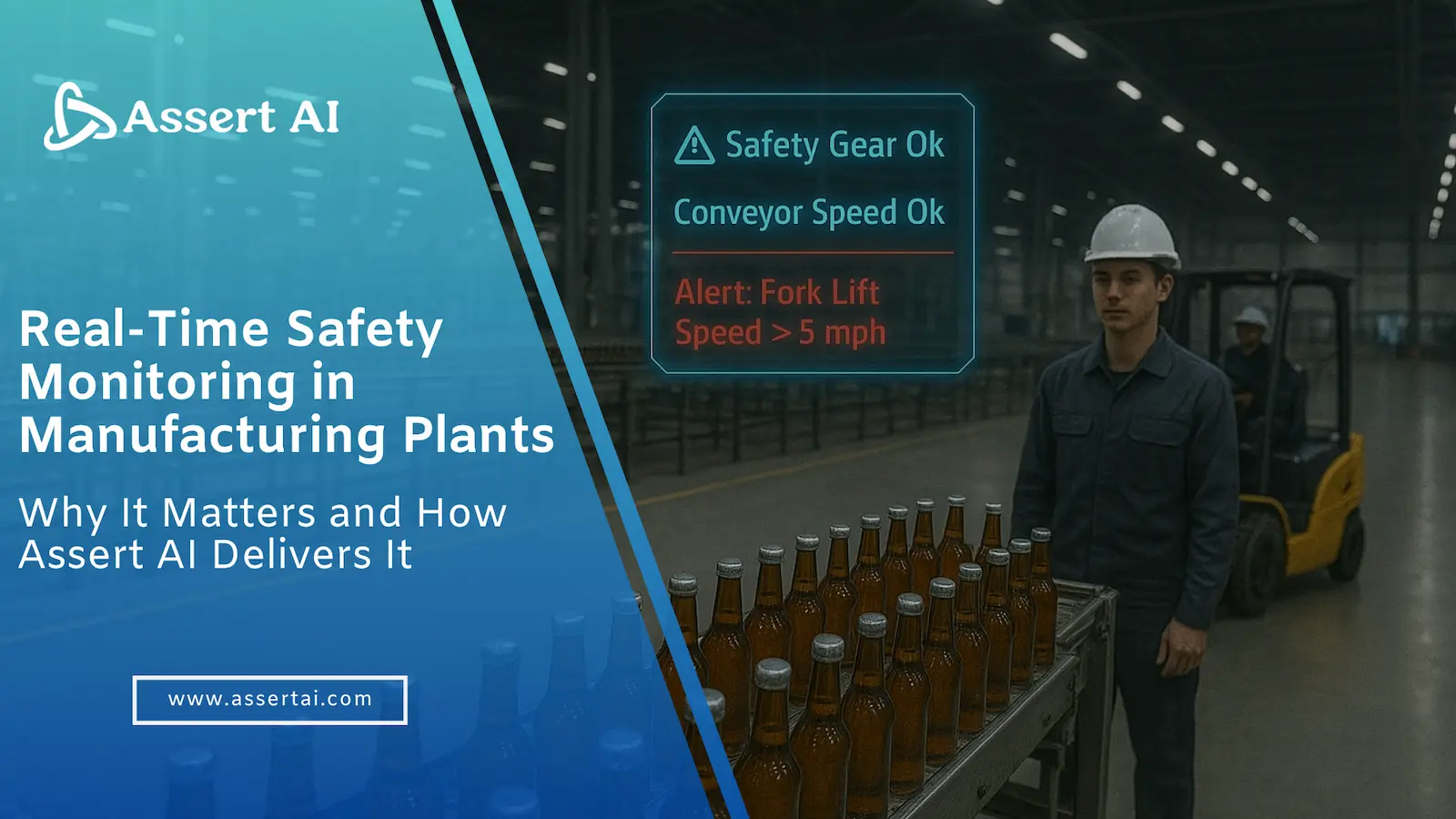

Occupational Health and Safety

Workplace safety is a universal priority, yet manual monitoring often leaves critical blind spots. With Assert AI’s technology, plants and warehouses can automatically detect whether workers are wearing the right PPE, ensure safe forklift operations, and identify obstructions in aisles or restricted zones. The system also flags overcrowding, unsafe vehicle movements, or near-miss events in real time. This proactive approach helps enterprises prevent accidents before they occur, reducing both human risk and corporate liability while fostering a culture of accountability.

By providing live alerts, the system helps prevent incidents before they escalate.

- Clients have reported up to 40% fewer workplace incidents within the first six months of deployment.

- Insurance premiums and safety compliance costs have also decreased, improving the bottom line while creating safer workplaces.

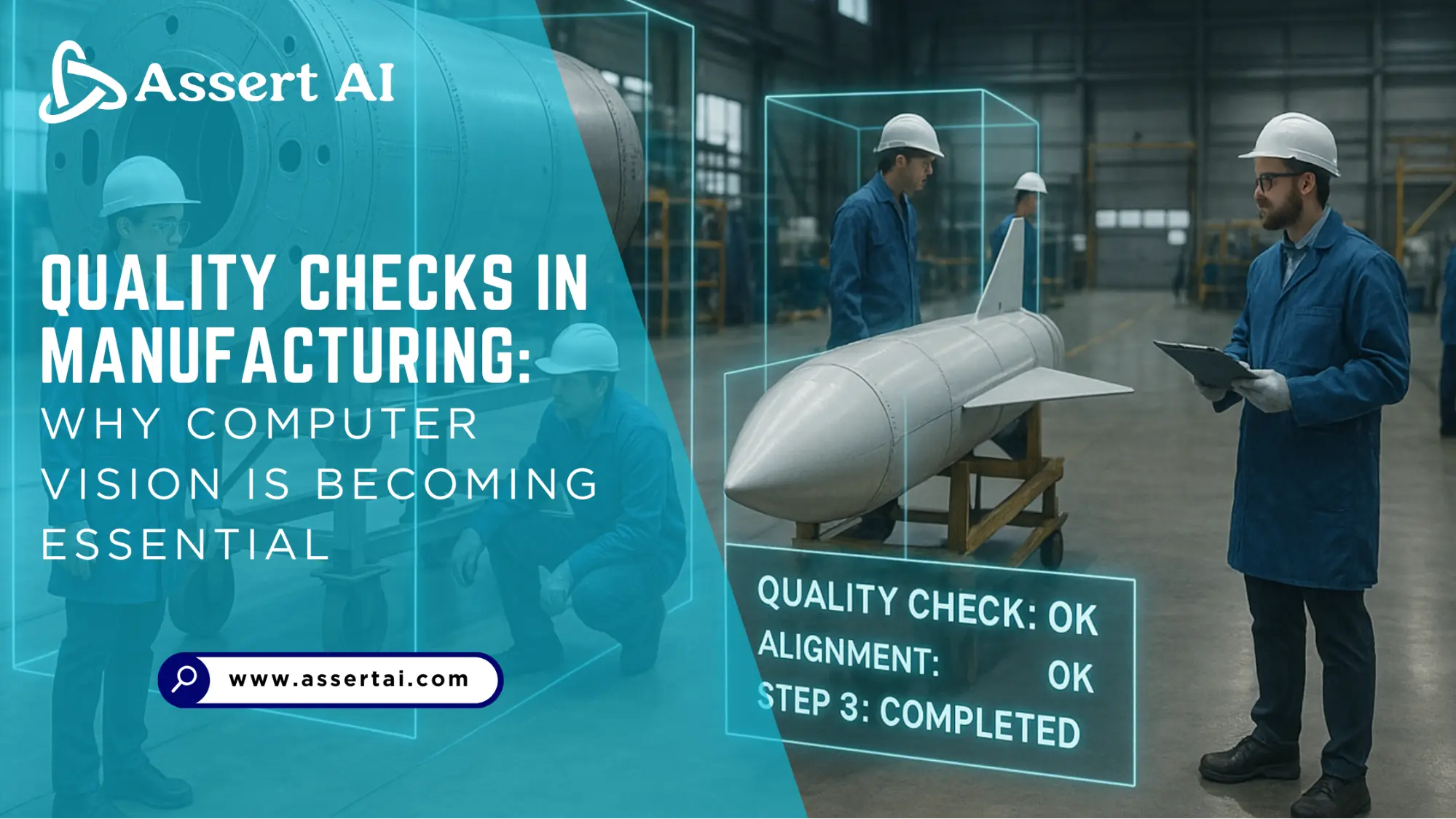

First Pass Yield Improvement

In industries where even a small defect can lead to costly recalls or wasted material, first pass yield (FPY) is a vital metric. Assert AI integrates directly into production lines to monitor every stage of assembly or layup. For example, in composite manufacturing, the platform validates whether each ply is laid correctly before allowing the process to move forward. This ensures products meet specifications the first time, minimizing rework cycles and material scrap. This results in higher production efficiency, reduced costs, and consistent quality standards.

- Plants using the system have achieved 20–30% improvement in first pass yield (FPY).

- Rework cycles have been cut by nearly 25%, saving time, manpower, and materials.

Customer Experience and NPS Improvement

Retail and QSR operators know that today’s customer values speed and convenience as much as product quality. Assert AI enables outlets to track customer queues, wait times at POS counters, and drive-thru throughput in real time. Alerts are triggered if counters are unmanned or service lags behind benchmarks. This not only streamlines service but also translates directly into higher Net Promoter Scores (NPS) and repeat business. By aligning staff deployment with live demand, businesses can maximize both customer satisfaction and revenue.

- Drive-thrus have reported 15–20% faster service times, reducing average wait per customer.

- NPS scores improved by up to 12 points, reflecting better customer satisfaction and repeat visits.

One Intelligent Dashboard, Complete Control

What sets Assert AI apart is its umbrella approach– integrating these diverse capabilities into a single, intelligent dashboard. This gives decision-makers a live, panoramic view of operations across sites and geographies. Every detection, every alert, and every metric is consolidated into one platform, allowing enterprises to monitor everything in real time with granular detail. From strategic planning to on-the-floor interventions, leaders gain unmatched visibility and control, ensuring their operations run safely, smoothly, and profitably.

Spotlight on Windergy 2025

Assert AI is set to participate in Windergy India 2025, to be held in Chennai from October 29–31, 2025. At Hall H7, Booth A109, the company will showcase ORBIT—its latest innovation designed specifically for the wind energy sector.

ORBIT (Optimized Real-Time Blade Inspection and Tracking) ensures flawless wind blade manufacturing by validating every ply layup against SOP requirements. Compatible with leading laser projection systems like LAP and Virtek, ORBIT has already been deployed at one of the largest wind blade manufacturing plants in India.

The results are undeniable:

- $200,000+ annual savings in scrap and rework costs.

- Near-zero defects in inspected blades.

- Faster cycle times without compromising quality.

With a proven ROI, ORBIT demonstrates how Assert AI is reshaping advanced manufacturing with AI computer vision solutions purpose-built for high-value industries.

For more details or to explore how Assert AI can support your organization, contact info@assertai.com