A Closer Look at AI Safety Management

At its core, AI safety management is about moving from reactive to proactive safety strategies. Traditional methods like manual inspections, random audits, or post-incident investigations are limited by human oversight and time constraints. They often catch risks only after they’ve already escalated. AI flips this model by enabling continuous, intelligent, and real-time monitoring of workplaces, ensuring risks are identified and managed before they can cause harm.

Here’s how it works in detail:

1. Detecting Unsafe Worker Behavior

One of the most common causes of workplace accidents is non-compliance with basic safety protocols, such as not wearing personal protective equipment (PPE). With AI safety management, computer vision systems integrated into existing CCTV cameras can automatically detect when workers skip helmets, gloves, reflective vests, or safety harnesses.

- Example: If an employee enters a restricted area without a hard hat, the AI system can instantly flag the violation and notify supervisors. Some setups can even lock machinery until compliance is restored.

- Impact: This reduces dependency on manual monitoring, ensures consistent enforcement, and fosters a safety-first culture.

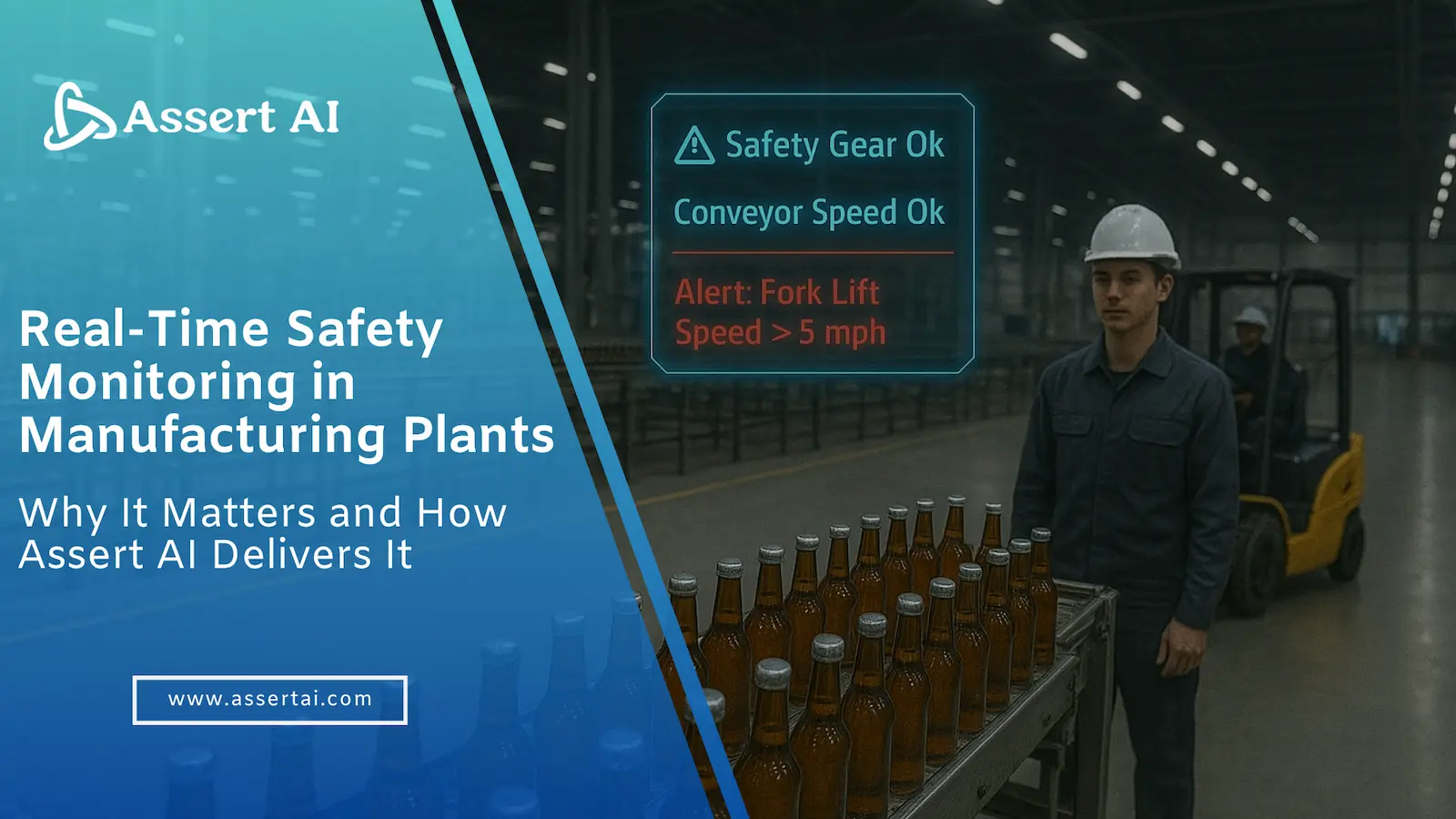

2. Monitoring Equipment and Vehicles

Industrial environments are filled with moving machinery and vehicles, forklifts, trucks, cranes, each posing a safety risk if misused. AI safety management uses sensors and video analytics to track their speed, route compliance, and proper functioning.

- Example: If a forklift exceeds the speed limit inside a warehouse, the system can alert operators or even slow it down via integration with IoT controls.

- Impact: This prevents collisions, minimizes equipment wear, and ensures compliance with operational safety rules.

3. Identifying Potential Hazards in Real Time

Hazards aren’t always the result of human error. They can be environmental or situational too. AI safety management identifies anomalies that could create unsafe conditions.

- Examples of Detected Hazards:

- Obstructions on walkways and evacuation paths.

- Spillage of liquids or chemicals in production areas.

- Overcrowding in restricted zones such as chemical storage areas or assembly lines.

- Obstructions on walkways and evacuation paths.

- Impact: By identifying these hazards as they appear, AI systems allow immediate corrective action, preventing accidents and operational slowdowns.

4. Predicting Risks Before They Escalate

The true power of AI safety management lies in its predictive analytics. By analyzing historical safety data and ongoing patterns, AI can forecast where risks are likely to occur.

- Example: If data shows that a particular machine tends to overheat after a certain number of hours, the system can recommend preventive maintenance before a breakdown or fire hazard occurs.

- Another Case: By studying worker movement data, AI can predict where congestion will build up in a plant, helping managers redesign workflows to reduce accidents.

- Impact: Predictive insights save both lives and costs, moving safety management from firefighting mode to a strategy of risk anticipation and prevention.

Why This Matters

Unlike reactive measures, safety management automation creates a safety net that’s always active, unbiased, and adaptive. It doesn’t get tired, overlook small details, or delay interventions. Instead, it continuously protects workers, machinery, and assets while giving managers actionable insights to refine processes.

Why Businesses Cannot Ignore AI Safety Management

1. Human Safety is Non-Negotiable

Industrial accidents cost lives and tarnish reputations. With AI based safety, companies can create real-time layers of protection, identifying unsafe practices before they escalate.

2. Financial Impact of Safety Lapses

Every accident comes with medical costs, insurance claims, equipment damage, and downtime. Proactive AI safety management reduces these financial risks by preventing accidents from happening in the first place.

3. Regulatory Compliance Made Easier

Governments and regulators worldwide are tightening safety requirements. AI systems provide audit trails, automated documentation, and compliance reporting that make life easier for managers and safety officers.

4. Boosting Productivity Alongside Safety

Safe environments are productive environments. When workers feel secure, efficiency rises. AI safety management ensures that safety protocols enhance, not hinder, workflow.

How AI Safety Management Works in Real Time

AI safety management combines three core components:

- Computer Vision: Cameras and sensors feed live data, detecting unsafe behaviors such as speeding forklifts or missing helmets.

- Machine Learning Models: Algorithms learn from historical data, flagging patterns that suggest potential hazards.

- Alerts and Interventions: When deviations occur, AI can trigger alarms, send notifications to supervisors, or even stop machinery until issues are resolved.

Example: In a manufacturing plant, if a worker enters a restricted area without a helmet, the AI system can instantly alert supervisors or pause nearby machinery. That real-time intervention prevents accidents before they occur.

Where Can AI Safety Management Be Applied?

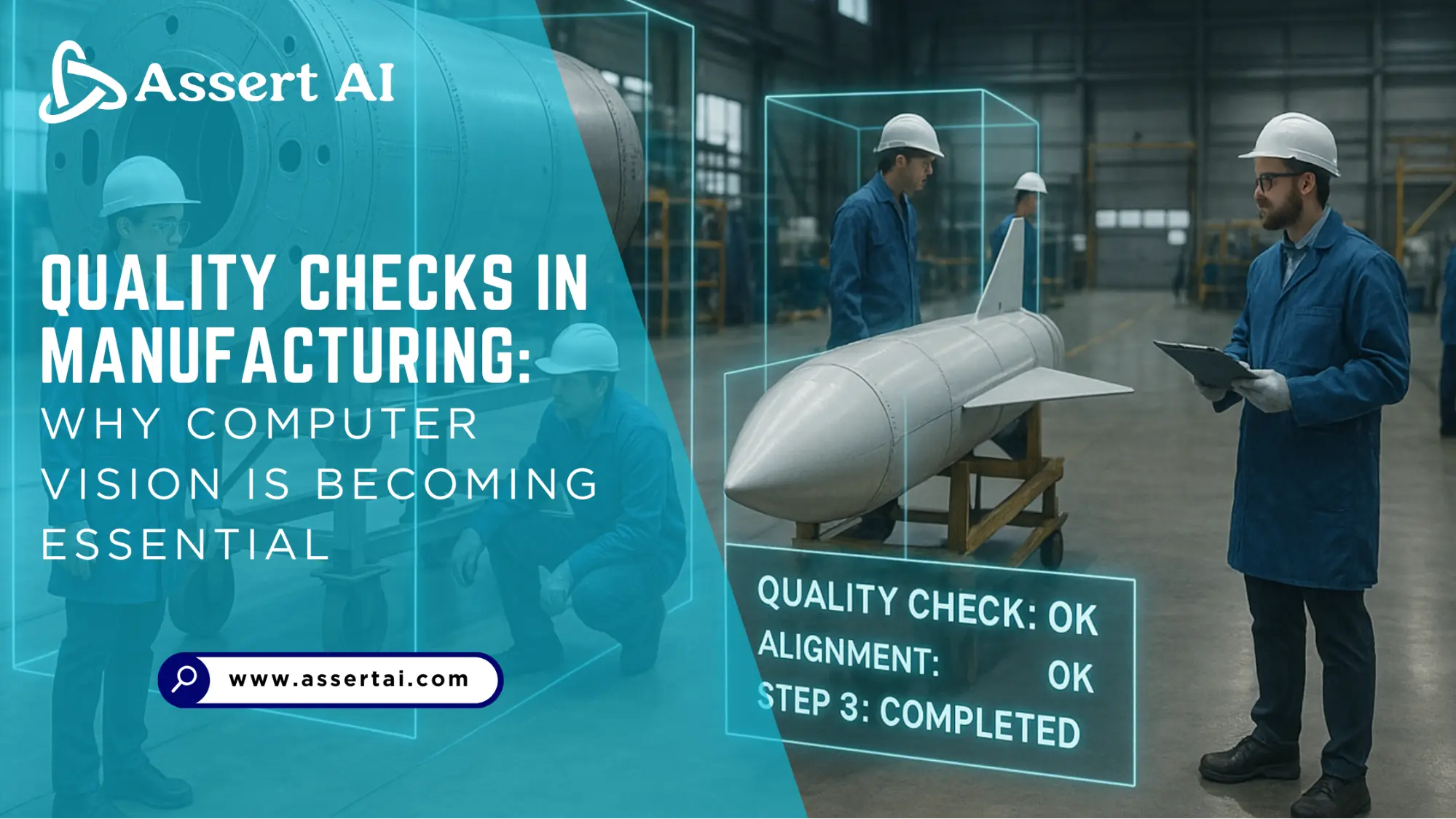

- Manufacturing Plants: Detect unsafe handling of heavy equipment, improper storage of materials, and missed SOPs.

- Warehouses and Logistics: Monitor forklift speeds, vehicle entry/exit, and pathway obstructions.

- Construction Sites: Track PPE compliance and prevent entry into high-risk zones.

- Chemical and Energy Industries: Identify leakages, equipment malfunctions, or unsafe handling of hazardous materials.

Common Questions About AI Safety Management

Q1: Is AI reliable enough to handle workplace safety?

Yes. Modern AI models have high accuracy rates and continuously improve as they process more data, making them reliable partners in safety monitoring.

Q2: Will implementing AI safety management require replacing existing infrastructure?

Not necessarily. Most AI solutions can integrate with existing CCTV and monitoring systems, making adoption cost-effective.

Q3: Does AI replace human safety officers?

No. AI safety management enhances human decision-making by handling repetitive monitoring tasks, freeing safety officers to focus on strategic improvements.

Q4: Can small and medium enterprises afford AI safety management?

Yes. Scalable, edge-based AI solutions now allow SMEs to adopt AI safety tools without massive upfront investments.

The Future is Built on AI Safety Management

In a world where every second of downtime and every safety lapse can lead to staggering losses, businesses can no longer afford to leave safety to chance. AI safety management offers a future-ready solution that doesn’t just reduce risks but actively drives efficiency, compliance, and trust.Organizations that embrace AI safety management today will not only protect their people but also position themselves as leaders in innovation and responsibility tomorrow.