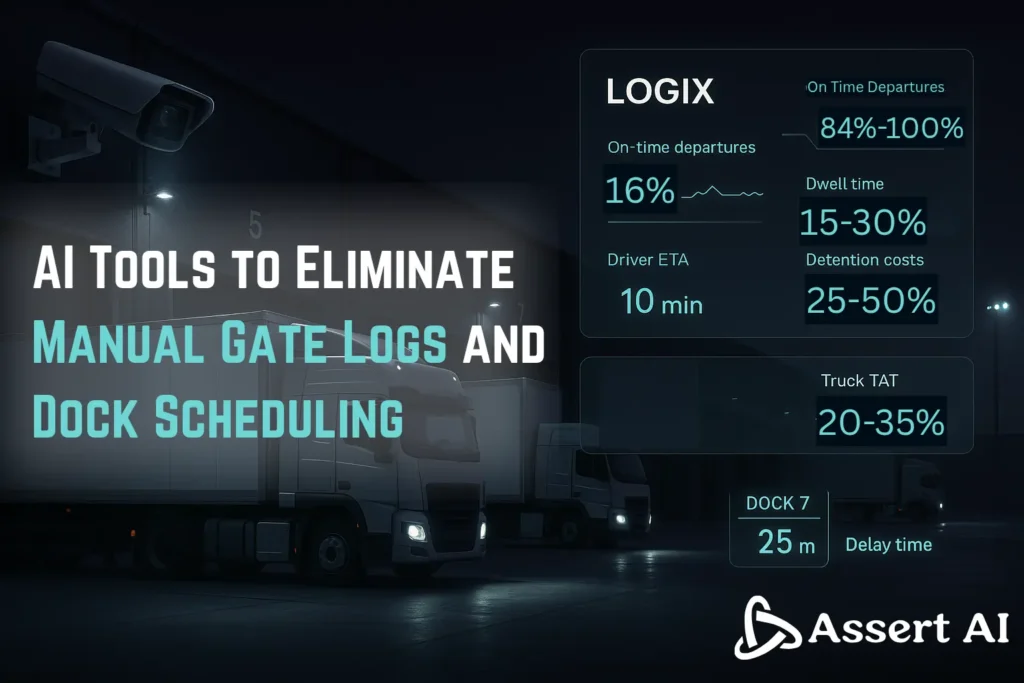

How Assert AI automates truck entry/exit logs, dwell time, and dock assignments with AI Productivity tool LOGIX

Warehouses don’t lose time in hours. They lose it in seconds that stack up- a driver waiting for a guard to type a plate number, a dock held because the last trailer wasn’t released in the system, a forklift circling because a door assignment changed on paper but not in reality. Multiply that across shifts and sites, and you’ve got a silent tax on throughput.

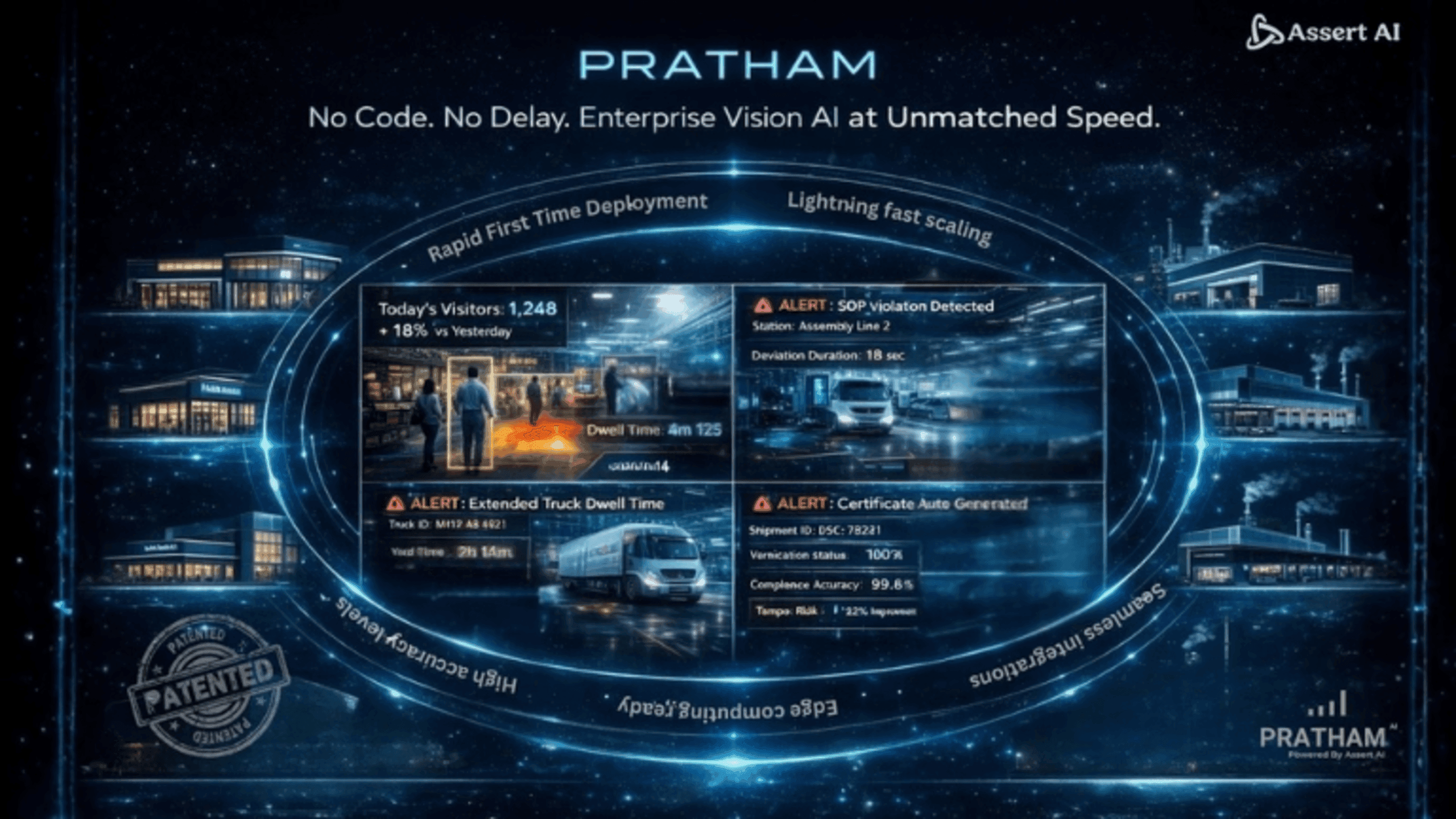

This guide unpacks how computer vision (CV) and AI-driven yard orchestration retire clipboards for good through auto-logging gate events, calculating dwell in real time, and assigning docks dynamically. We’ll anchor the discussion around LOGIX, Assert AI’s one of the AI productivity tools for real-time yard and dock visibility.

The cost of manual yard operations (and why it’s still a thing)

- In a yard management survey 22% of respondents still ran gate processes on paper. FourKites

- ATRI found that 94.5% of fleets levy detention fees. Trucking Research

- Driver dwell time at each pickup/drop is ~119 minutes on average. FreightWaves+1

- Detention often runs $50–$100 per hour once the free window expires. Velostics

Meanwhile, the dock & yard management systems market is scaling fast (from $2.34B in 2024 toward $7.27B by 2033, 13.6% CAGR), reflecting the industry’s pivot to real-time control as per Grand View Research.

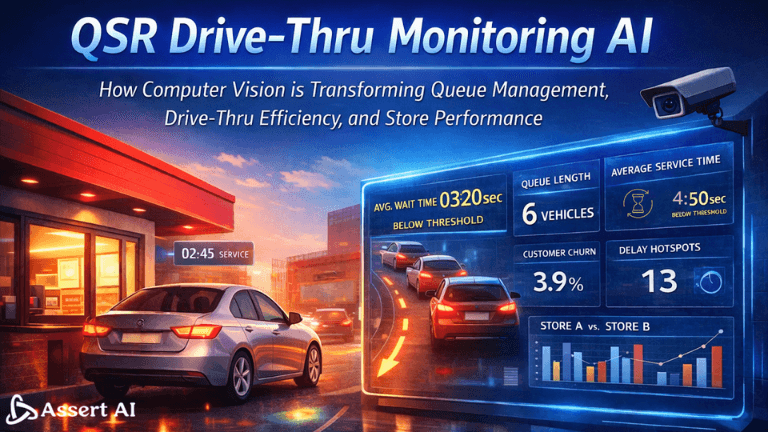

What “CV-powered yard orchestration” actually means

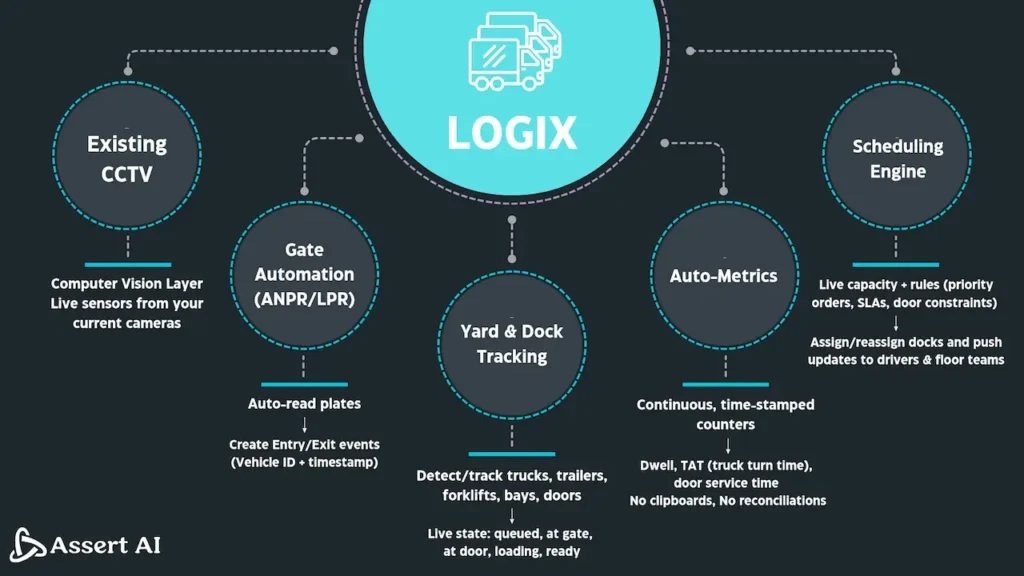

Computer vision turns your existing CCTV into a live sensor:

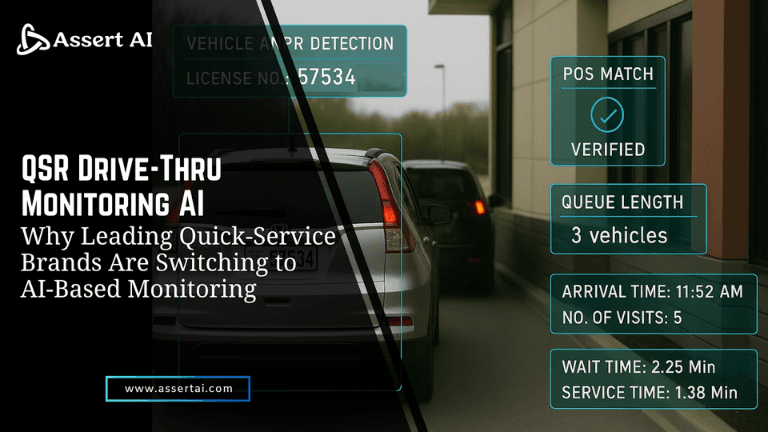

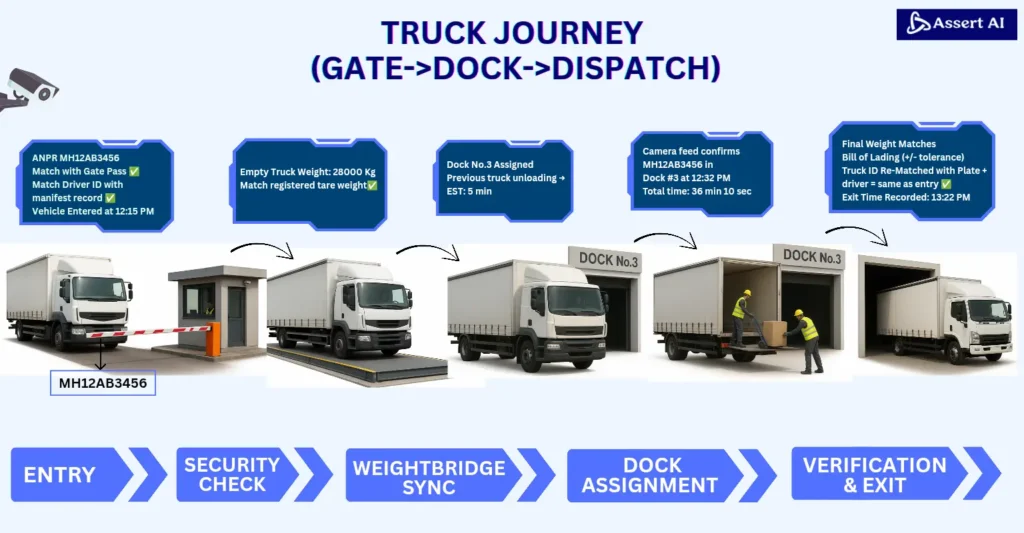

- ANPR/LPR reads plates automatically at the gate for precise entry/exit events tied to a vehicle ID.

- CV detects and tracks trucks, trailers, forklifts, bays, and dock doors to compute location and state (queued, at gate, at door, loading, ready to depart).

- With time-stamped events, the system calculates dwell, TAT (truck turn time), and door service times continuously- no clipboards, no reconciliations.

- A scheduling engine uses live capacity + rules (priority orders, carrier SLAs, door constraints) to assign/reassign docks and push updates to drivers and floor teams.

Why now? Beyond tech maturity, the Scheduling Standards Consortium (SSC) is pushing interoperable APIs for appointment data, reducing swivel-chair work across WMS/TMS/YMS.

LOGIX by Assert AI- What it does (and why your yard finally breathes easy)

LOGIX is a real-time situational awareness + decision layer for your yard. It watches every vehicle’s journey, proves what happened, and nudges the flow so SLAs don’t die in traffic.

Live visibility & proof (no more “who said what”)

Auto gate logs (ANPR/LPR): Instant in/out with plate read, timestamp, lane, and camera source.

Last known vehicle position (map view): Yard map with real-time dots per truck/trailer, coded by state (queued, at gate, at door, loading, ready to depart).

Challenging scenario solved: “Phantom truck” that supposedly waited 2 hours? LOGIX shows it actually parked offsite for 48 minutes between gate and dock.

Camera evidence for compliance: Auto-linked clips for milestones (arrived gate, reached door, chocks applied, loading start/stop).

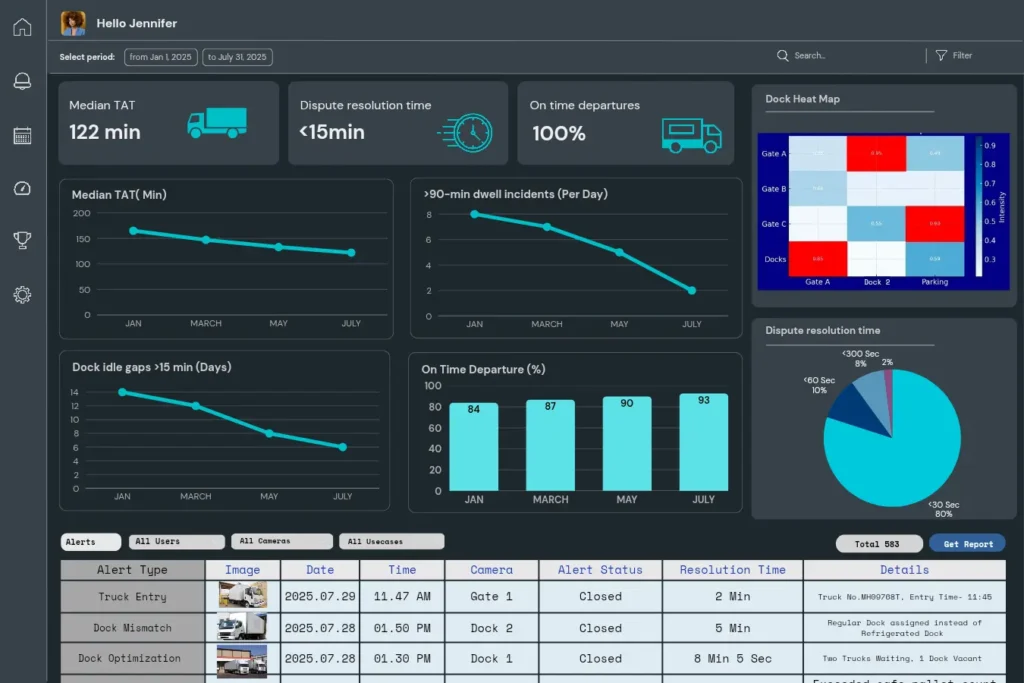

Yards typically save 20–40 minutes per dispute by sending a permalink instead of assembling ad-hoc screenshots.

Smart scheduling & orchestration (adaptive, not reactive)

- Dynamic dock assignments: Uses live capacity + rules (door type, staffing, equipment, product constraints, temperature control) to pick the right door, not just the nearest one.

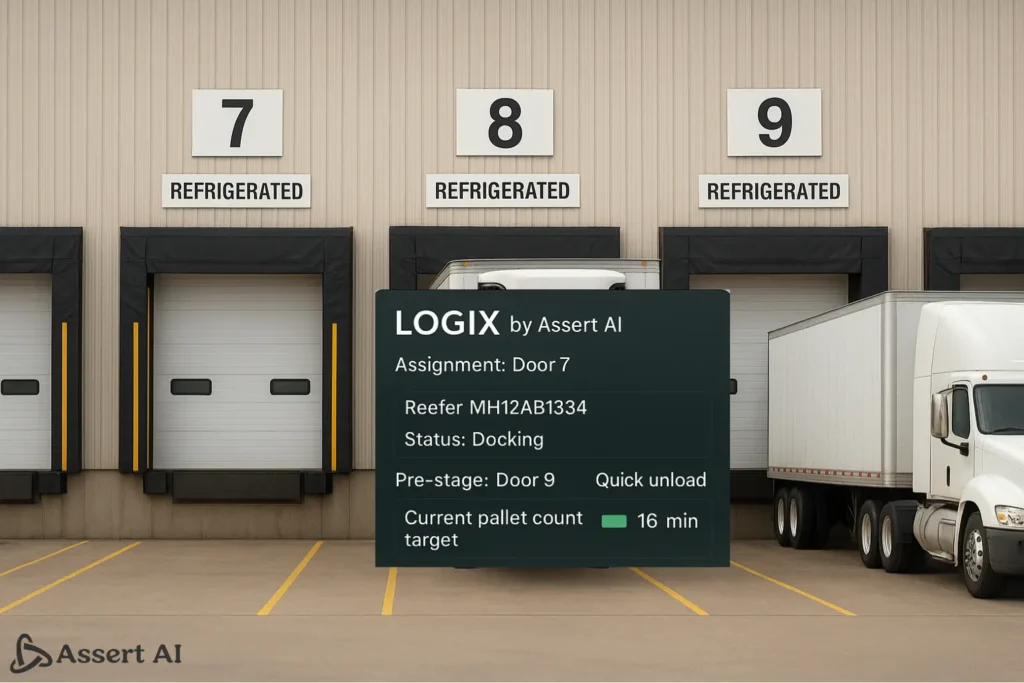

Challenging scenario solved: Two reefers show up; only one refrigerated door is free. LOGIX assigns Door 7 to the earlier arrival and pre-stages Door 9 by signaling a quick unload on the current pallet-count target.

- Queue & dwell control: Real-time dwell counters; SLA-at-risk loads get a quiet priority bump.

Example metric: Carriers breaching 90-min dwell drop by 25–35% after week 2 of rollout.

Exception automation: Automatic triggers for overstay, no-dock-assigned, weight mismatch, wrong door, missed appointment, double-booked door.

Challenging scenario solved: A 32-ton outbound shows weight mismatch vs manifest → LOGIX flags scale cam + bay cam, halts gate pass, and routes to re-check before detention starts ticking.

The messy yard problems LOGIX quietly fixes

- Two trucks, one door, zero patience

The scene is familiar: two trucks roll in, but only one dock is open. The radios crackle, the ground team scrambles, and drivers grow restless. Instead of messy reshuffles, LOGIX immediately spots the overlap, scans for compatible doors, and reassigns based on SLA priority and travel distance. Drivers see the new bay on their screen or phone instantly. What used to be a 10–15 minute standstill dissolves before it even builds.

- Wrong door, wrong product

A chilled bay suddenly gets an ambient load; thats a classic case of “wrong truck, wrong door.” Left unchecked, it means forklifts have to pull everything out and start again. LOGIX prevents the headache by cross-checking door rules with the arriving truck’s plate context. The mismatch is flagged before unloading begins, the door screen locks, and the system reroutes. A full restage cycle- often 30-40 minutes- is saved without anyone breaking a sweat.

- Ghost dwell

Carriers sometimes report more site time than your gate logs suggest. In one case, a driver claimed 2.5 hours on site, but the system showed only 1.6. LOGIX stitches together the camera trail and ANPR gaps, exposing the real story: a 50-minute offsite break. Instead of disputes and back-and-forth phone calls, managers close the case with one shared link and evidence.

- Weighbridge roulette

Few things drain productivity like catching an overweight load at the exit scale. The truck has to circle back, docks must be freed, and loaders are pulled off schedule. LOGIX steps in early, flagging potential overweight loads as soon as the scale reading appears, while tying the event to service times and loader shifts. Patterns emerge- for example, “Mondays, Shift B” enabling targeted retraining. In practice, overweight incidents drop by more than 40%.

- Missed appointment pile-ups

Every yard has seen it: the clock hits noon, and suddenly the parking lot is gridlocked. LOGIX’s predictive queue notices the crunch forming at 11:40, sends nudges to carriers, promotes early arrivals, and pushes less urgent loads past lunch. The result? Peak-hour gate congestion falls by nearly a quarter, and yard flow stays intact.

How LOGIX Works

1) Ingest & perception

- Video ingest from existing CCTV (RTSP/ONVIF).

- ANPR/LPR models (OCR + plate detection) at gate lanes.

- Object detection + multi-object tracking for trucks/trailers/forklifts, with zone geofences for gates, staging, lanes, docks.

- Edge inference (GPU box on-prem) keeps latency low; metadata only goes to cloud if you want — helping with privacy and cost.

2) Event graph & metrics

- Each crossing creates events (Entered Yard, At Staging, At Door 12, Departed).

- A state machine safely infers dwell, service time, door idle/blocked, queue length, and TAT.

- Confidence thresholds + evidence snapshots link every metric to underlying video.

3) Scheduling & control

- Slot model per door (capacity by hour, constraints), predictive ETA from historical gate→door times, and heuristics/ML to recommend the next best door.

- API connectors to WMS/TMS/ERP and SSC-aligned appointment APIs where supported.

- Human-in-the-loop: supervisors can override with reason codes, which feed continuous improvement.

4) Security & governance

- Role-based access (guard, yard supervisor, planner, carrier).

- Audit trails for every change or override.

- Evidence vault for carrier/customer disputes and compliance.

Turning Blind Spots into Live Signals with AI productivity tools

Paper gate logs → trusted digital trail

ANPR-based timestamps tie arrivals/departures to a verifiable ID, eliminating manual entry errors and back-and-forth on detention disputes.

“First-come first-served” chaos → appointment reality

Where facilities still operate FCFS (with no paper trail), LOGIX layers live capacity, priorities, and constraints to sequence doors intelligently.

Unknown dwell → quantified dwell

Continuous counters and heatmaps expose bottlenecks (e.g., door 7 is a chronic slow spot on Mondays 10–12). Industry context: ~119 minutes average dwell, with extreme over-4-hour cases still present.

Carrier chargebacks & detention → fewer disputes

With synchronized gate and door evidence, who-waited-for-whom becomes a report, not an argument. Detention fees $50–$100/hr concentrate stakeholders’ attention.

Static schedules → dynamic orchestration

When a door goes down or staffing shifts, LOGIX rebalances doors and alerts drivers early, to avoid yard pile-ups.

Expected Outcomes

Every site starts at a different baseline, but these are practical, defensible targets many operations model when implementing AI productivity tools like CV-powered yard orchestration:

- Dwell time: ↓ 15–30% average within 8–12 weeks

- Truck TAT: ↓ 20–35% through gate/D2D cycle time reductions

- Detention costs: ↓ 25–50% via better slotting + evidence-backed decisions (and fewer unpaid hours)

- Door throughput: ↑ 10–20% from dynamic reassignments and earlier prep

- Manual effort at gate: ↓ 60–80% (data entry, reconciliations, call/email churn)

- Dispute time: ↓ 50–70% (evidence links directly to events)

Note: ranges above are planning targets, not guarantees; real results depend on baseline processes, door constraints, staffing, and carrier compliance.

Why these AI productivity tools are future-proof

- Standards momentum: Appointment data is moving to API-based, interoperable exchanges (SSC), trimming manual touchpoints.

- Commodity hardware, smart software: Use the CCTV you already have; add edge compute where needed.

- Defensible evidence: Time-stamped video + machine events create a chain of custody for every claim.

- Market validation: Vendors and customers are investing: the dock & yard software market growth underscores durable demand.

Sources & further reading

- Vector — State of Yard Management eBook 2023: multi-site YMS adoption gaps.

- ATRI (American Transportation Research Institute) — Detention payment rates and impact. Trucking Research

Grand View Research — Dock & Yard Management Systems market size/CAGR.

Also Read: Beyond the WMS: Why AI in Warehouse Management Is Now Mission-Critical

Ready to see your yard in real time?

If your operation still leans on periodic checks and static logs, you’re flying blind between updates. LOGIX brings live gate events, true dwell, and dynamic dock scheduling onto one screen, with the evidence to back every decision.

Let Assert AI show you how to stop the leaks and safeguard your bottom line. Get in touch with us today.