When a wind turbine blade fails, the consequences ripple far beyond the factory floor. Production schedules derail, multimillion-dollar assets are lost, and the credibility of renewable energy projects comes under scrutiny. AI in quality assurance is increasingly being recognized as a crucial safeguard against such costly failures. In 2024, a GE Vernova blade at the Vineyard Wind project off Massachusetts shattered due to insufficient bonding, triggering investigations and beach closures. That same year, a 72-meter Siemens Gamesa blade weighing 22 tonnes snapped off a turbine in Norway’s Odal Vind farm, adding to mounting safety concerns. In March 2025, a Nordex turbine at the Frontier Windpower II project in Oklahoma collapsed without warning, despite calm weather, baffling both engineers and locals. Just six months later, in September 2025, all three blades of an EWT turbine at Aviva’s Perth, Scotland site tore away in a catastrophic failure, narrowly avoiding injuries.

These incidents underscore a harsh truth: even the most advanced turbine designs and manufacturing methods remain vulnerable to hidden defects or weaknesses that are often invisible to the naked eye. Preventing such failures not only protect billion-dollar infrastructure, it also safeguards communities, ecosystems, and the public’s trust in renewable energy.

The Hidden Threat of Insufficient Bonding

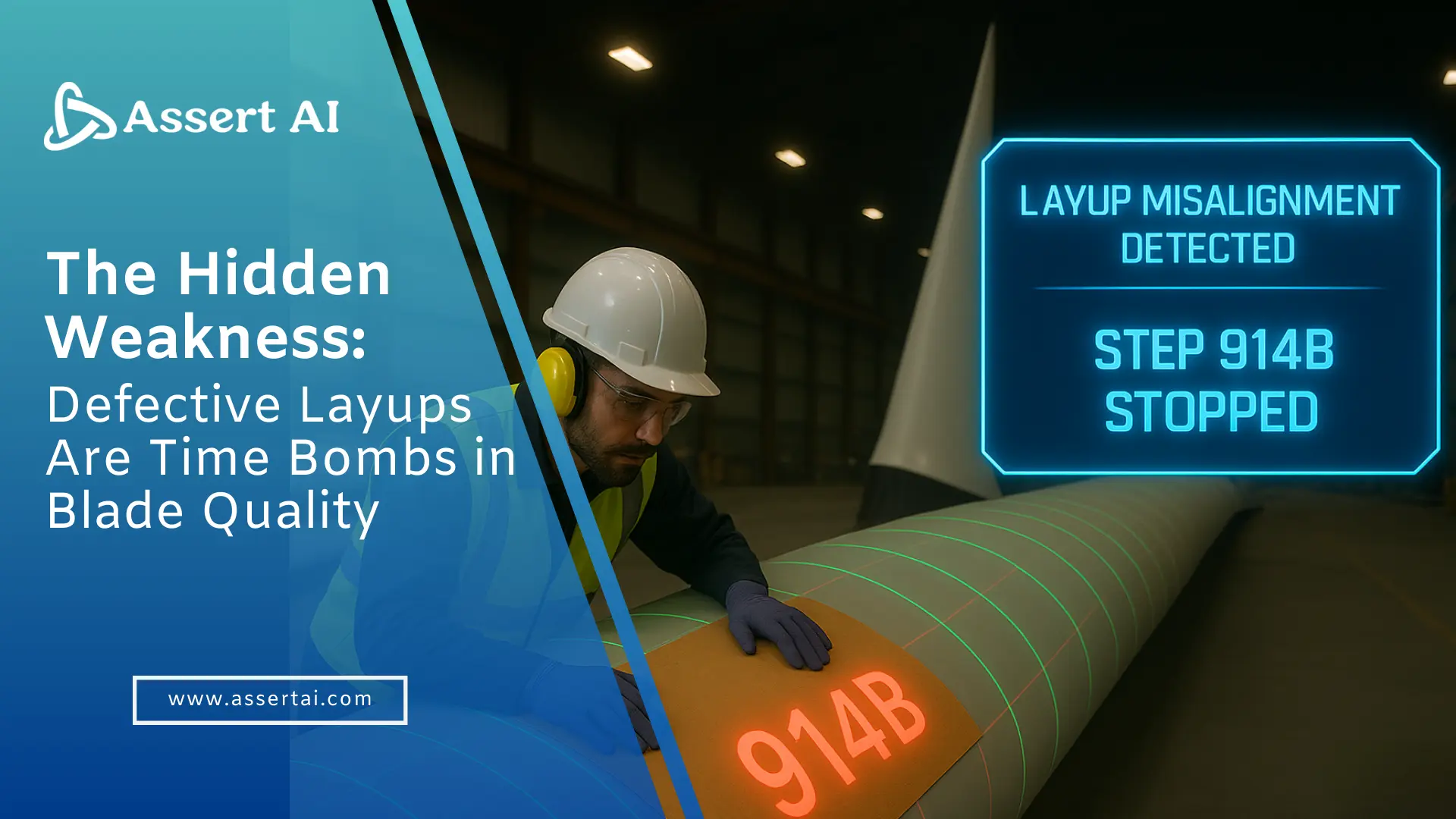

Wind turbine blades are massive composite structures, often stretching more than 100 meters in length. Their strength relies on perfect bonding between fiber layers and complete resin infusion. Yet in practice, several challenges can compromise structural integrity:

- Dry patches during resin infusion that create weak spots.

- Uneven resin distribution, leading to resin-rich or resin-poor regions.

- Incomplete bonding between layers, resulting in delamination under stress.

Even small voids or unbonded areas can propagate cracks, causing premature failure in the field. As the Vineyard Wind incident highlighted, these failures can be catastrophic, not only financially but also reputationally for renewable energy providers.

For a deeper look at the financial implications of defects like insufficient bonding, read The Cost of Poor Quality in Composite Manufacturing and How AI in Quality Assurance Can Help.

Why Traditional Quality Checks Fall Short

Historically, quality assurance in blade manufacturing has relied on:

- Manual inspections: Visual checks by skilled technicians.

- Ultrasonic testing or thermography at later stages.

- Process logs from infusion machines.

While necessary, these methods have limitations:

- Human inspectors can miss subtle defects, especially in large, complex blades.

- Post-production checks detect problems too late- often after hours of labor and material investment.

- Manual valve operation during resin infusion introduces the risk of premature closure, which can trap air pockets and cause voids.

These challenges create a clear need for a more reliable, real-time monitoring solution.

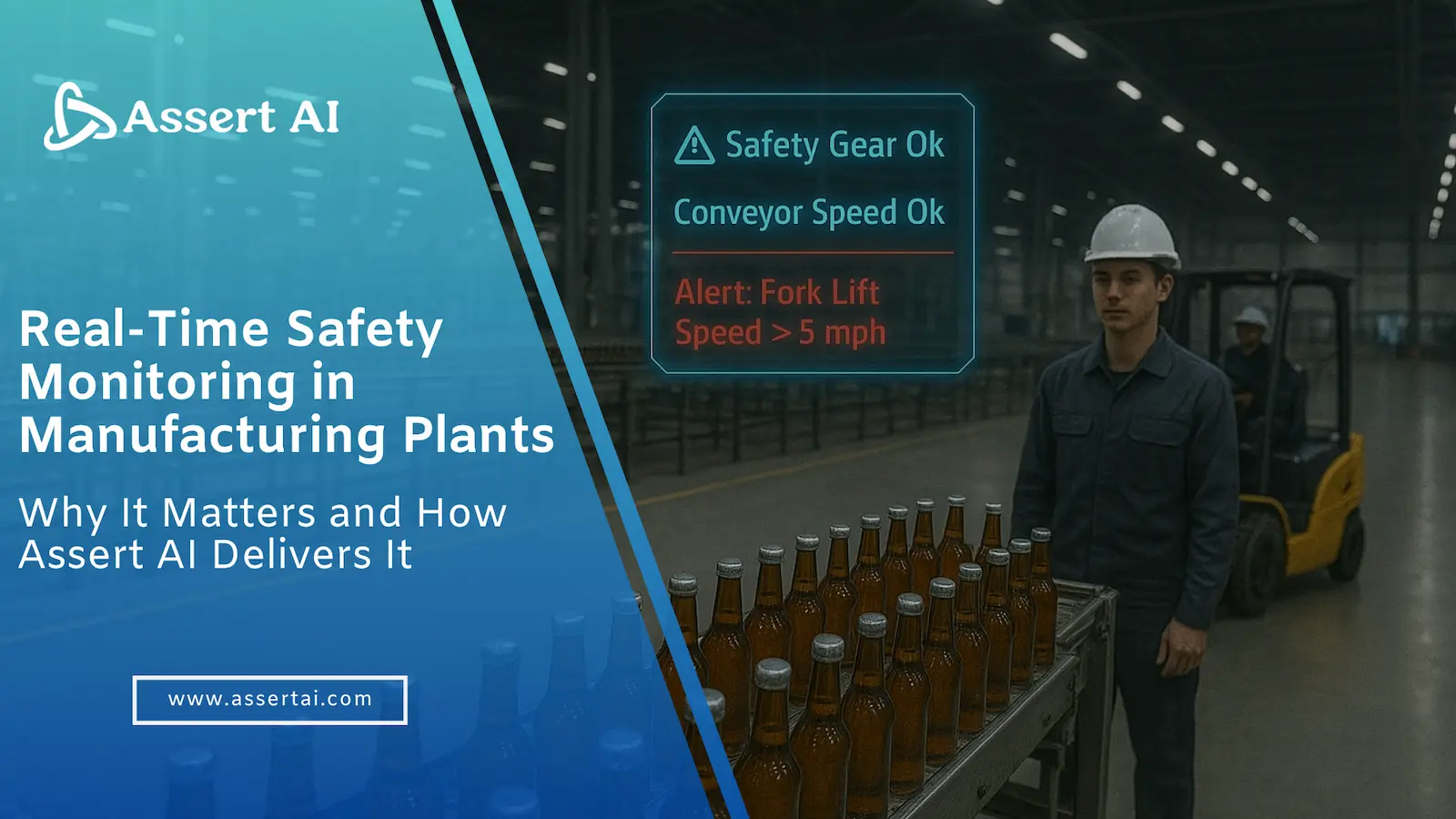

Computer Vision in Resin Infusion Monitoring

Advances in computer vision (CV) and AI-driven quality assurance are transforming composite manufacturing. By deploying cameras and AI models on the production line, manufacturers can achieve:

- Real-time resin flow tracking: Detecting incomplete wet-out or dry patches as they happen, not hours later.

- Automated defect detection: Identifying potential bonding issues, resin starvation, or trapped air bubbles that would otherwise go unnoticed.

- Data-driven quality records: Creating digital audit trails for compliance, customer transparency, and continuous process improvement.

For a comprehensive overview of how CV is changing manufacturing, read Quality Checks in Manufacturing: Why Computer Vision Is Becoming Essential.

Closing the Loop with Smart Valve Control

One of the most powerful applications of computer vision in blade production is automated valve management during resin infusion. Traditionally, technicians manually decide when to open or close valves, which can lead to human error and uneven resin flow. By integrating ai in quality assurance with the resin infusion system:

- Valves remain open until AI detects full and even resin saturation.

- Automated closure occurs only when bonding is verified, reducing the risk of dry patches.

- Operators receive real-time alerts and visual confirmation dashboards, enabling quick interventions.

This closed-loop system ensures that bonding integrity is validated as the process unfolds, preventing defects before they occur, instead of discovering them during costly rework or after a catastrophic failure in the field.

Building a Stronger Future for Wind Energy

The renewable energy sector is under immense pressure to deliver reliable, sustainable solutions at scale. Preventing avoidable failures like insufficient blade bonding is critical not only for project economics but also for public trust.

By adopting AI-powered computer vision systems and integrating them directly with resin infusion valves, manufacturers can set a new standard for quality assurance: one that minimizes risk, reduces waste, and accelerates the clean energy transition.At Assert AI, we’re committed to helping manufacturers lead this shift. Our Quality Checks in Manufacturing framework and our insights on the Cost of Poor Quality in Composites outline proven strategies to make wind energy safer, more efficient, and more sustainable.

The future of wind energy depends on invisible bonds. With computer vision and AI-driven monitoring, we can make sure those bonds hold – literally and figuratively.