Whether you are ready for it or not, problems do occur, but you cannot overlook some of the most common warehousing mistakes that affect productivity & increase costs. There is no single way to manage a warehouse. Managing a warehouse is a job that requires a lot of organizing & planning. Managing inventory in a warehouse has always been challenging, and the ever-changing logistics trends make it more difficult. It’s time you get proactive, identify the common problems & learn about their solutions.

To stay updated on how your warehouse should be managed, and ensure that no undue costs are generated in the supply chain, take note of these 8 common warehousing mistakes and also learn ways to identify & avoid them.

Warehousing Mistake #1 – Bad Inventory Management

Storing too much inventory in a little space, or choosing the wrong storage layout for the goods in the warehouse can lead to a very common warehouse problem ‘Bad Inventory Management. If you are spotting some items at the wrong location, realizing that you don’t have sufficient stock, or finding stock after you have already rejected the order, there is definitely some problem with inventory management. Inaccurate inventory records & placing inventory wrongly cause a lot of problems in a warehouse. Storing obsolete inventory in the warehouse is a very common warehouse problem- it just occupies the required space and affects productivity.

Did you know?

Around 43% of small businesses in the United States either don’t track inventory or use a manual system for doing so.

The worldwide cost of inventory distortion is estimated at around $1.1 Trillion, this includes shrinkage, stockouts, and overstocks

But this is unacceptable and needs immediate solutions.

How to Avoid:

Adopting advanced technology can help solve your your common warehousing mistakes concerning stock shortage, excess inventory & obsolete inventory. An advanced AI-based WMS offers visibility into the entire warehouse inventory & helps to avoid any issues related to managing & updating inventory.

AI-based WMS helps to automatically update the status of inventory whenever it is received, stored, or shipped. AI-based systems can read barcodes effectively using OCR technology. This system will help you to track inventory in real-time, and have a clear status of each inventory from putting away, storage, and picking to obsolete inventory.

Choosing the right WMS for your business will help you to maintain proper inventory at any given time, especially for fulfilling seasonal demand hikes. You can even perform cycle & physical counts very efficiently.

Also Read:

Warehousing Mistake #2 – Holding Excess Inventory

We all know reducing inventory & setting a minimum stock threshold limit is a good practice for any warehouse, but storing too much stock is still the most common mistake made by supply chain companies globally.

Are you among those who fall for the trap of volume discounts and end up buying too many units of a single product? But you need to realize reducing inventory levels as much as possible makes your supply chain productive.

Lack of proper inventory track or manual tracking can end up in an excess stocking. Excess inventory often leads to poor quality & degraded goods. If you are maintaining high levels of stock, you will have low inventory turnover. As a result, the excess stock that sits on warehouse shelves for a long deteriorates & perishes. Maintaining excess stock & having too much money tied up in inventory reduces available cash flow. No business wants a cash flow shortfall.

How to avoid:

Inventory optimization using the right technology is the solution to this problem. Having a proper & updated inventory tracking system can help you order only what is required instead of overstocking.

Where the operations are only manual, physical stock audits are required to prevent overstocking, but with an AI-based inventory management system stock audits are done in real-time saving a lot of time, effort & cost.

Warehousing Mistake #3- Poor Warehouse Layout

The most common problem faced by warehouse owners is the lack of space, not because warehouses are small but because of poor optimization of the available space. Efficient use of space is a critical issue in warehousing today. Poorly planned warehouse layout is a cause of plenty of warehouse accidents too. Finding the optimal layout that uses vertical space while leaving enough space for employees is important.

You cannot dismantle an entire warehouse to create a new more efficient layout but what you can do is proper planning & choosing the right solution

How to avoid:

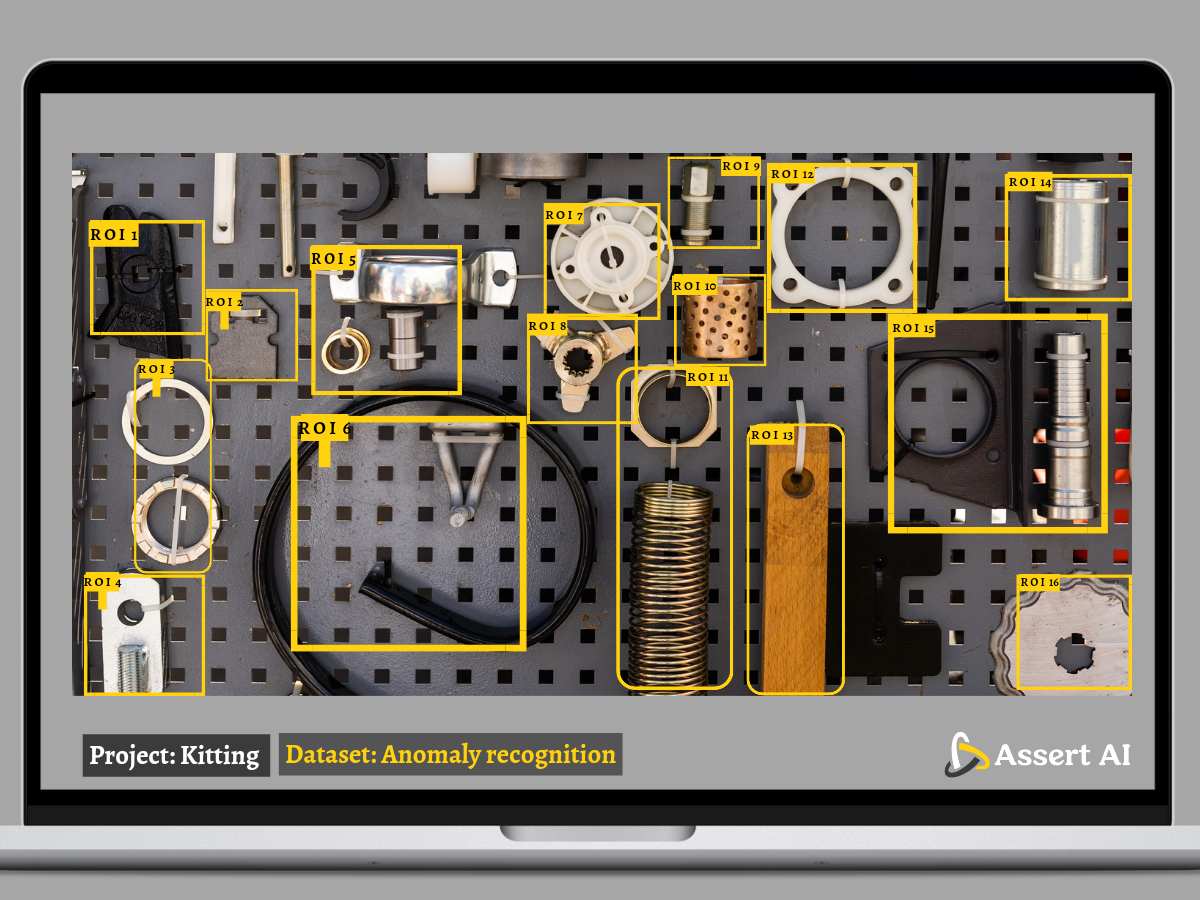

Automated equipment & technology are the solutions. AI-based automated systems like empty space detection show the floor & vertical space available for use. Also, object detection & tracking ensures that the highest-selling inventory is easily accessible. Employing forklifts allows maximum utilization of available space. AI-based systems can do space optimization in real-time, which will reduce labor costs & also categorize the inventory providing proper accessibility.

Warehousing Mistake #4 – Higher Labor Costs

Warehouse managers mostly assume technology is expensive. For them, going for automation is expensive, but hiring more labor is a cheaper option. However, this is not true for long-term business.

Warehouses need employees for different operations but higher labor costs seriously affect business. Warehouse staff range from cleaners, packers, and security guards, to managers & administrators.

It is estimated that labor constitutes around 65% of the total operating budget in most warehouses.

Being a warehouse manager, you obviously want to cut down on this labor cost while maintaining the productivity level.

Read more warehousing related statistics

How to avoid:

The labor-related problems can be addressed with two main strategies-maximizing available labor & replacing labor with automated systems. Although leveraging automated systems does cost money, it helps save money in the long term as well. AI-based systems can replace employees in different tasks like using AI-based security surveillance that helps in 24/7 real-time tracking without any need of a security guard. Using technology for different warehouse operations can help higher-level managers to focus on more important tasks while reducing the need for employees at lower-level operations. Automation will help reduce human errors and improve overall time completion for different processes. Today, all warehouses need to have a proper balance between technology & employees.

Warehousing Mistake #5- Poor Damage Control

There are multiple warehousing mistakes for product damage. Inventory damage & having poor damage control is another critical problem in warehousing. Product damage leads to significant revenue loss. Supply chains can suffer unexpected losses resulting from broken, defective, crushed, and bent goods. Unexpected losses are frustrating for managers who are competing in highly competitive markets. It is likely that you think damaged products are inevitable and part of the cost of doing business, but much of this can be prevented. Accidents can happen, but the rate of workplace mishaps that damage stock or injure workers can be greatly reduced.

Damage control in a warehouse is a high priority for warehouse managers. They need to reduce the business cost by looking at the root cause of an accident where products are damaged. To reduce inventory damage, you know you’ll have to make some changes. Businesses always have room for improvement.

How to avoid:

There is no more effective way to prevent damage than automating your operations. Manual production tracking is very inefficient and prone to human errors. For best damage control, we strongly recommend that you deploy AI-based systems in your warehouse. It helps to keep track of production levels, generate real-time reports & give instant alerts in case of any damage. AI-based video analytic systems can track inventory for any damages during production, picking, packaging & outbound. Alerts triggered for goods mishandling also help big time. Automation can work at a consistent pace for improving the quality of output & reducing accidents due to human errors or fatigue.

Warehousing Mistake #6- Clinging on to Paper Processes

We’re living in a paperless digitalized era, but failing to utilize technology and sticking to inefficient, paper-based processes is a very common warehouse management mistake mostly in small organizations.

Are you still managing your warehouse operations with pen & paper? If yes, you are also making the same management mistake that most of the small warehouses are making.

More than 80% of the warehouses today have no automation whatsoever.

If you are thinking that your business is better with just a few paper processes and doesn’t need any latest technology then you are certainly on the wrong path. This will ultimately bring down productivity & cause delays from lost or misplaced documents.

Common warehousing mistakes like refusing to adopt new technology and not optimizing your data will not only cause inefficiencies but also leave your business less competitive. Manual processes cannot timely respond to changing market trends and shifting customers. What you need is automation.

How to avoid:

Choosing automation and eliminating your paper-based processes will cut costs, improve accuracy & help the environment. But that doesn’t mean that you have to invest in an expensive or complex warehouse management system. Simple tools using AI-based technology like smart dashboards, barcode scanners, intelligent surveillance, and automated data collection can help you digitize your warehouse and automate warehouse operations.

Warehousing Mistake #7- Inadequate Health & Safety Management

A tidy or organized warehouse isn’t necessarily a safe & secure warehouse. Proper safety management includes looking for hazards that may threaten your employees. But mostly the health & safety of employees gets overlooked in many big & busy warehouses. Believing that as long as employees suffer no accidents everything is fine, in a big warehousing mistake.

Are there accidents due to equipment failure in your warehouse? Do you get early alerts in case of any fire or smoke? Are your employees safe from moving forklifts? If yes, then you are certainly making mistakes with your health & safety management. The truth is that warehouses do not focus on the health & safety of workers, and the consequences can be fatal.

Safety Status quo is not good enough- As per OSHA, more than 5000 workers on average die on the job every year.

As per the US Department of Labor, around 20-30% of slip-and-fall accidents at the workplace cause moderate to severe injuries, such as broken bones, head injuries, and spinal cord injuries

How to avoid:

Warehouses have always been a dangerous work environment, so properly analyzing accidents & implementing actions to eliminate them can help reduce costs & save several lives. Using technology for safety is not only important to check warehousing mistakes like not complying with OSHA, but also to reduce accidents & fatalities in the workplace. Adopting AI-based measures for health & safety management can be helpful. AI-based surveillance can help predict, prevent & avoid accidents. With the power of AI-based technology, you can monitor all sites 24/7 without any human intervention. The systems based on AI technology can track the sites in real-time and send instant alerts in case of any dangerous situation for managers to take action proactively. AI can help identify machines & equipment that are not working properly and give the best solutions before any disaster happens.

Warehousing Mistake #8- Failing to Measure the Right Metrics

Most warehouses today fail to measure warehouse performance and establish proper Key Performance Indicators (KPIs). Despite being aware of the need for meaningful KPIs, many companies do not focus on performance measures and that is where they are stuck in the cycle of committing errors.

Are you aware of how much standard warehouse operations like receiving, picking, packing, and shipping cost you? What is the ROI? Who are the productive & unproductive employees? If not, then you then it is high time that you start tracking these important metrics.

If you are not able to differentiate good from bad and fail to understand where and how you can improve, you are definitely making mistakes in warehouse operations. No progress is possible without measuring the performance of your supply chain because you need to know where you are before moving forward.

How to avoid:

Automation & technology today is capable of providing valuable measure down to the minutest details. Tracking these important metrics is not a thing of the future now. The key performance indicators are a treasure of information.

You can customize warehouses using AI solutions as per your business operations to measure data that is meaningful for your company. AI-based solutions come equipped to track & store all the business data & can be easily connected to a smart dashboard to provide analytics in real-time. When you have analytics giving the appropriate KPI, you can have tools that need to correct any mistakes.

Our Final Recommendation

No business can be perfect all the time. Warehousing mistakes are common. Mistakes & failures will happen. But you don’t need to accept things the way they are. There are solutions to every problem. From what we discussed above about the most common warehouse management mistakes & how you can avoid them, we can conclude that answer lies in Warehouse Automation.

If you can avoid or prevent these 8 common warehousing mistakes, you can lead to better warehouse efficiency & productivity along with better customer satisfaction. Specialists at Assert AI know that there is no one solution to every warehouse problem. Our experts take time to understand your business challenges to create appropriate, customized solutions for your business needs.